Gear dynamic transmission error measurement method and measurement device

A measuring device and technology of transmission error, applied in the field of measurement of gear dynamic transmission error, can solve the problems of reducing the authenticity of gear transmission accuracy test, difficult to study and control vibration and noise, and inability to truly simulate the working state between gears, etc. The effect of avoiding distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following implementation manners, and all technologies realized based on the contents of the present invention belong to the scope of the present invention.

[0039] Such as Figure 4 As shown in the dynamic transmission error measurement process, the implementation steps of the gear dynamic transmission error measurement are as follows:

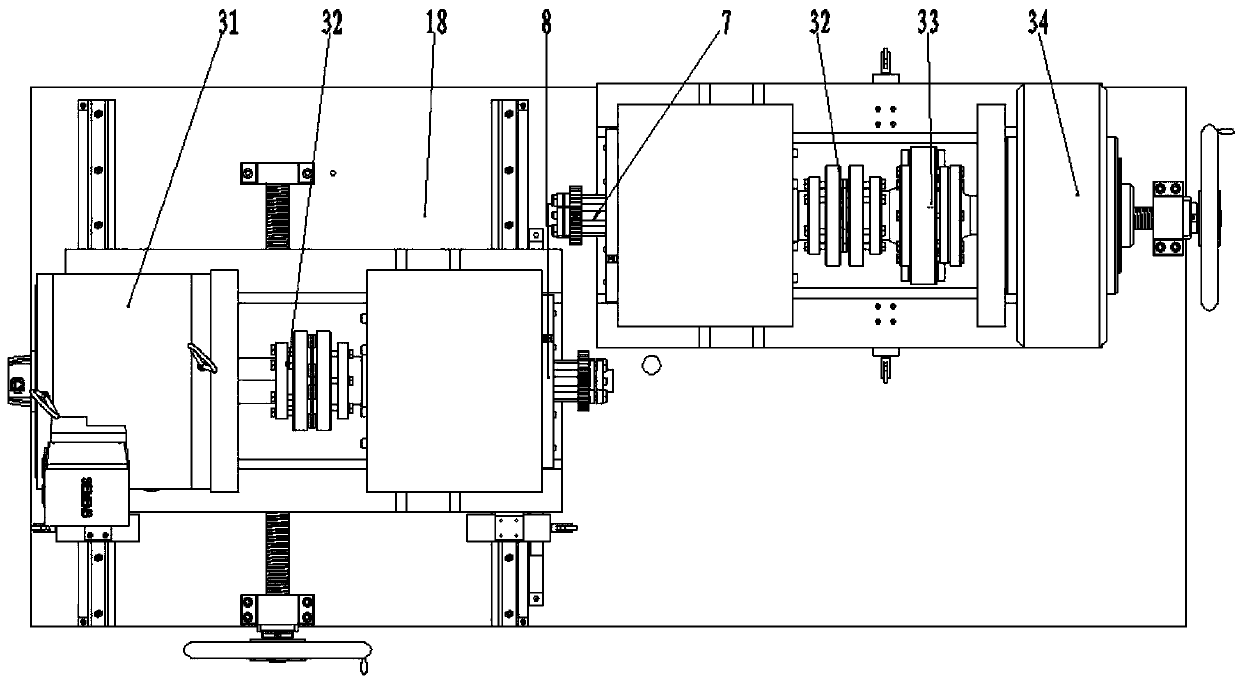

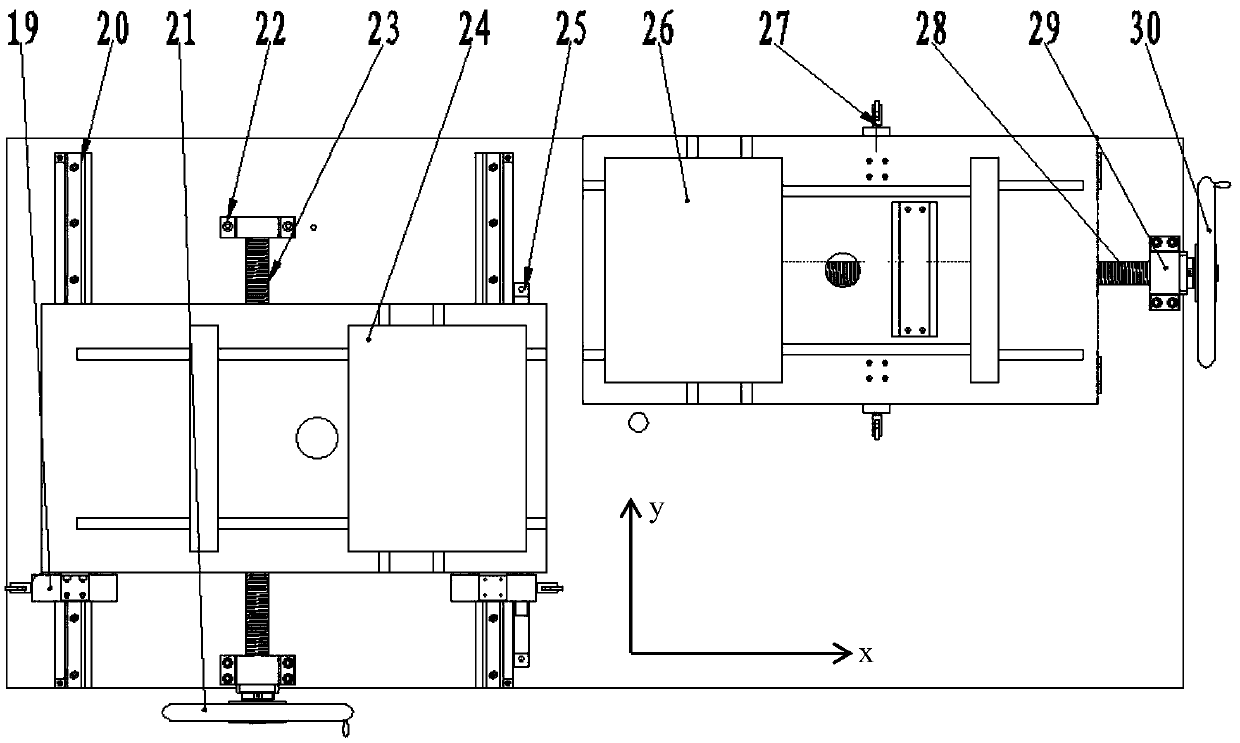

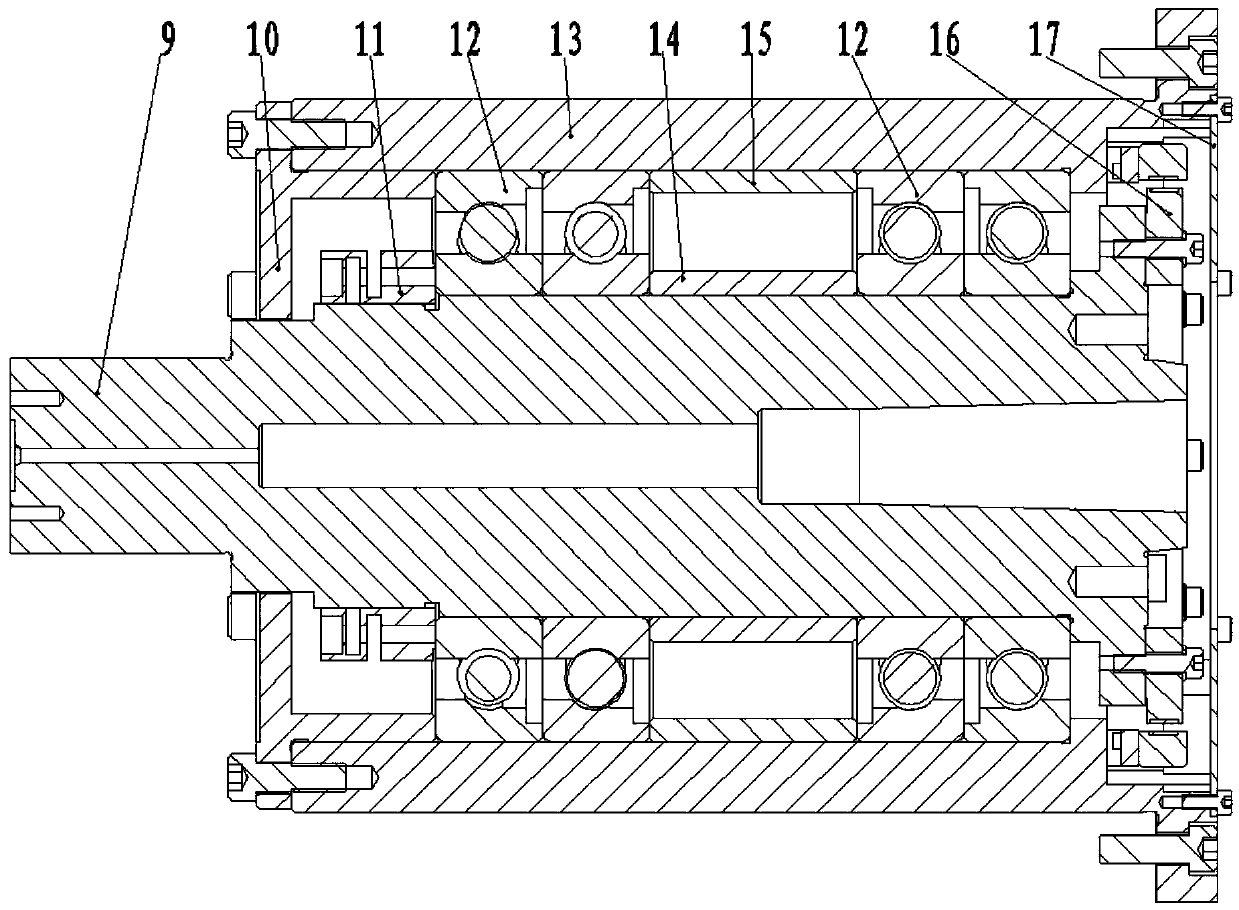

[0040] 1) Gear installation, ① Use the cooperation between the inner tapered surface of the short tapered shaft (4) and the tapered surface of the precision rotary shaft (8), and adjust the radial runout and end surface runout of the shaft system by means of screw adjustment. Check the installation accuracy of the short tapered shaft (4) until the runout accuracy of the shaft sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com