Spot welder mounting bracket capable of adjusting position of welding head adaptively

A technology for mounting brackets and spot welding machines, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient adaptive position adjustment, complex structure, limited application range, etc., and achieve the effect of facilitating spot welding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

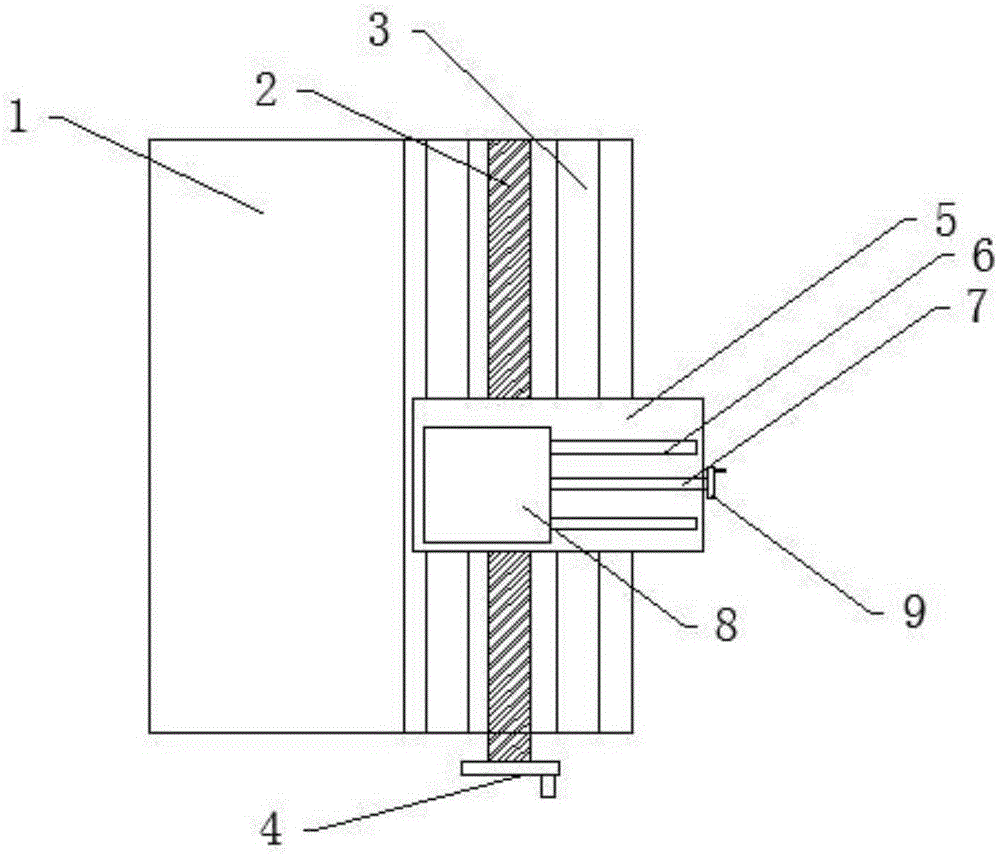

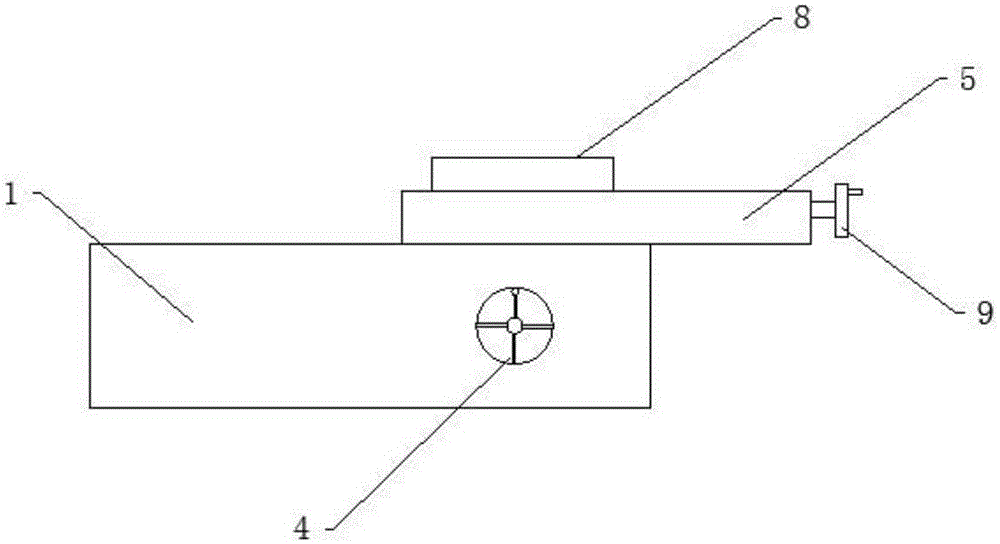

[0012] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

[0013] A spot welding machine mounting bracket capable of adaptively adjusting the position of the welding head, including a base 1, the base 1 is provided with a longitudinal adjustment mechanism and a horizontal adjustment mechanism, and the longitudinal adjustment mechanism includes a longitudinal screw rod 2 and a longitudinal guide rod 3 , longitudinal adjustment hand wheel 4 and longitudinal support plate 5, the top surface side of the base 1 is inwardly recessed to form an accommodation chamber, the screw rod 2 and the longitudinal guide rod 3 are longitudinally arranged in the accommodation chamber, and the longitudinal guide rod 3 Distributed on both sides of the longitudinal screw rod 2, the longitudinal guide rods 3 are two,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com