Method for testing fatigue life of gear of driving axle differential

A technology of fatigue life and test method, which is applied in the direction of machine gear/transmission mechanism test, machine/structural component test, instrument, etc., can solve problems such as unsuitable planetary gear, half shaft gear fatigue life, etc., and achieve easy promotion and use, method Simple and reliable, the effect of quality stability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

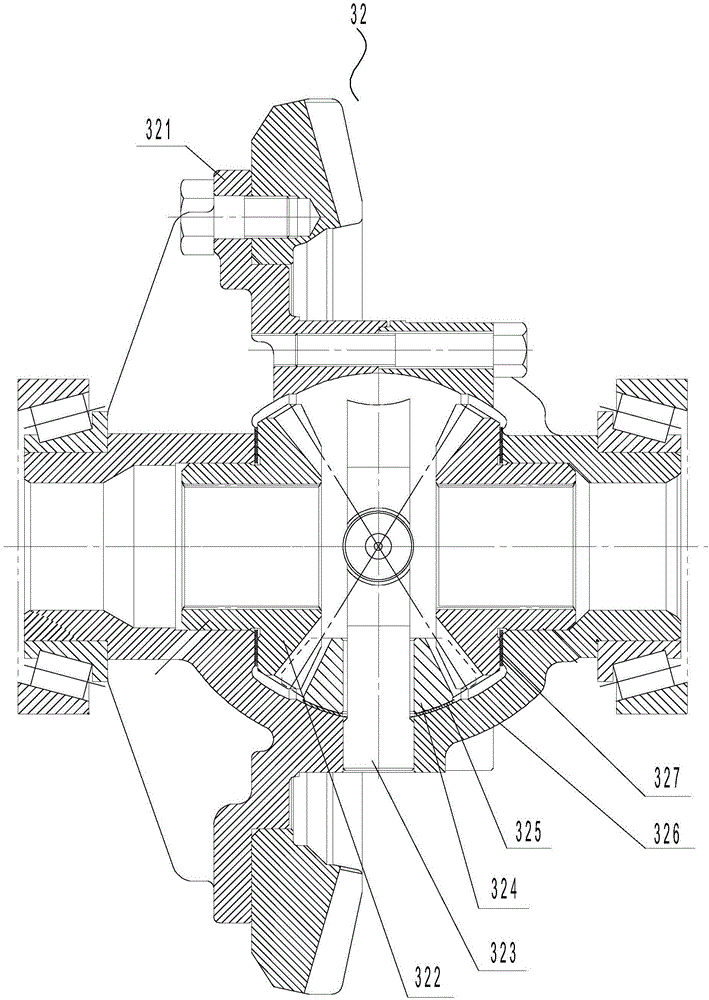

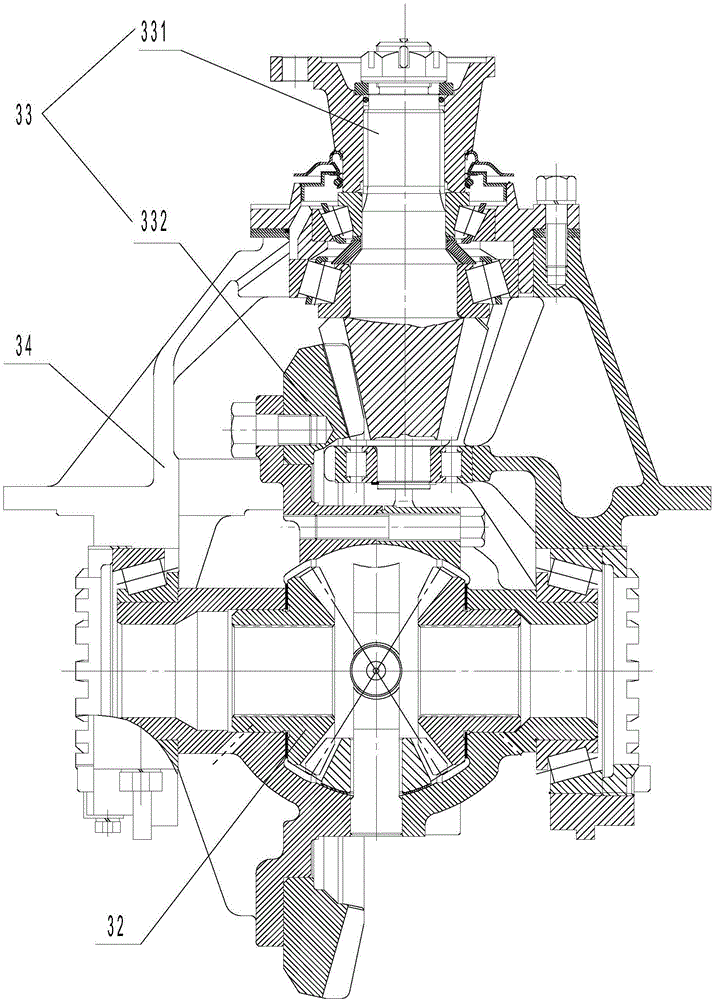

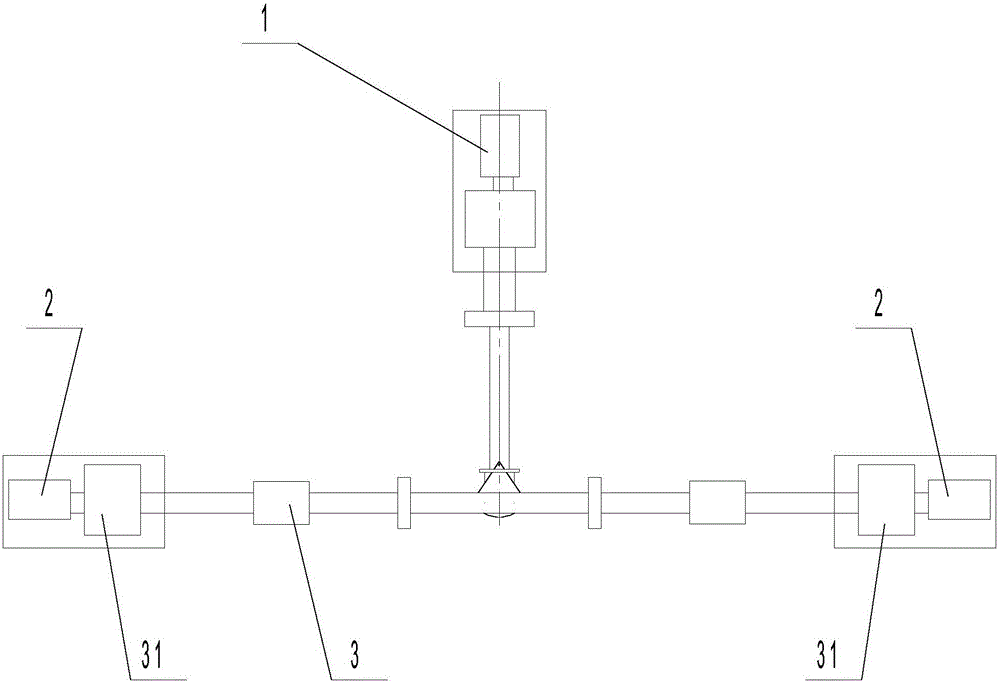

[0058] A driving axle differential gear fatigue life test method, the method is to first assemble the differential of the driving axle and the main cone assembly to form the main reduction assembly, assemble the main reduction assembly on the driving axle, and start the test , to simulate the working condition of constant differential speed, test the fatigue resistance times or time when the planetary gears and side gears fail, so as to determine the fatigue life of the planetary gears and side gears inside the differential, so as to determine whether the differential meets the requirements. Design requirements.

[0059] The simulated constant differential speed working condition is to control the speed and torque of the input end of the main cone to a constant value, and simultaneously control the speeds of the output ends of the two drive axles respectively, so that the speeds of the output ends of the two drive axles are not zero, but the speed difference remains constant. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com