Device heat transfer nondestructive failure analysis method and device

An analysis method and a lossless technology, applied in the direction of measuring devices, analyzing materials, and using radiation for material analysis, etc., can solve difficult non-destructive analysis, destructive failure analysis and other problems, to avoid time-consuming and cost-consuming, and save analysis Cost and time saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

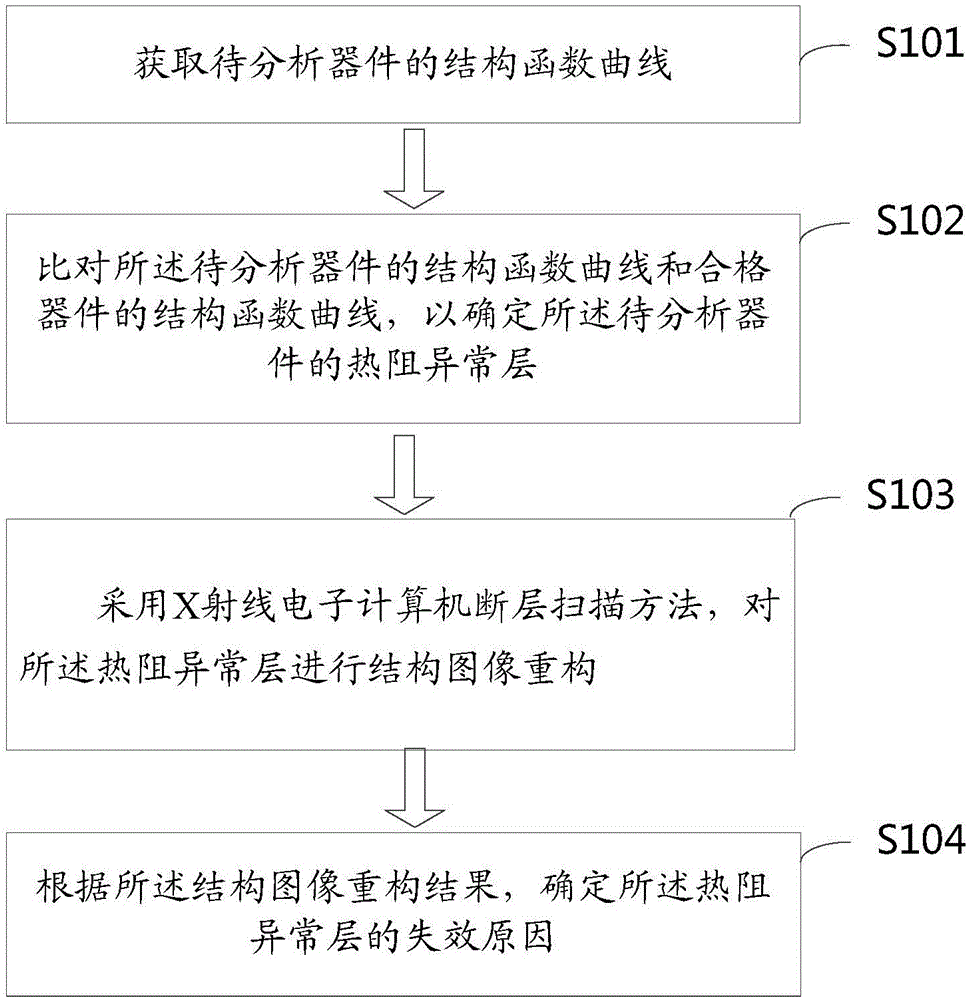

[0045] In this embodiment, a non-destructive analysis method for heat conduction of a device is provided, such as figure 1 Said, said method comprises:

[0046] Step S101, obtaining the structure function curve of the device to be analyzed;

[0047] Step S102, comparing the structure function curve of the device to be analyzed with the structure function curve of the qualified device to determine the abnormal thermal resistance layer of the device to be analyzed;

[0048] Step S103, using X-ray computerized tomography method to reconstruct the structural image of the abnormal thermal resistance layer;

[0049] Step S104, according to the structural image reconstruction result, determine the failure cause of the abnormal thermal resistance layer.

[0050] It should be noted that the method provided in this application is especially suitable for thick metal packaged power devices, because it is difficult to analyze layer by layer of thick metal packaged power devices using con...

Embodiment 2

[0074] In an embodiment, a device heat conduction lossless failure analysis device is provided, such as Figure 8 As shown, the device includes:

[0075] An acquisition module 801, configured to acquire the structure function curve of the device to be analyzed;

[0076] The comparison module 802 is used to compare the structure function curve of the device to be analyzed with the structure function curve of the qualified device, so as to determine the abnormal thermal resistance layer of the device to be analyzed;

[0077] The reconstruction module 803 is configured to perform structural image reconstruction on the abnormal thermal resistance layer by using an X-ray computerized tomography method;

[0078] The determination module 804 is configured to determine the failure cause of the abnormal thermal resistance layer according to the structural image reconstruction result.

[0079] It should be noted that the device provided by this application is especially suitable for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com