The method of selecting layer chasing or sidetracking after the horizontal section of the coalbed methane horizontal well breaks out

A technology of horizontal section and horizontal well, applied in the field of coalbed methane development, can solve the problems of increasing drilling cycle, reducing coalbed drilling rate, and wasting drilling cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

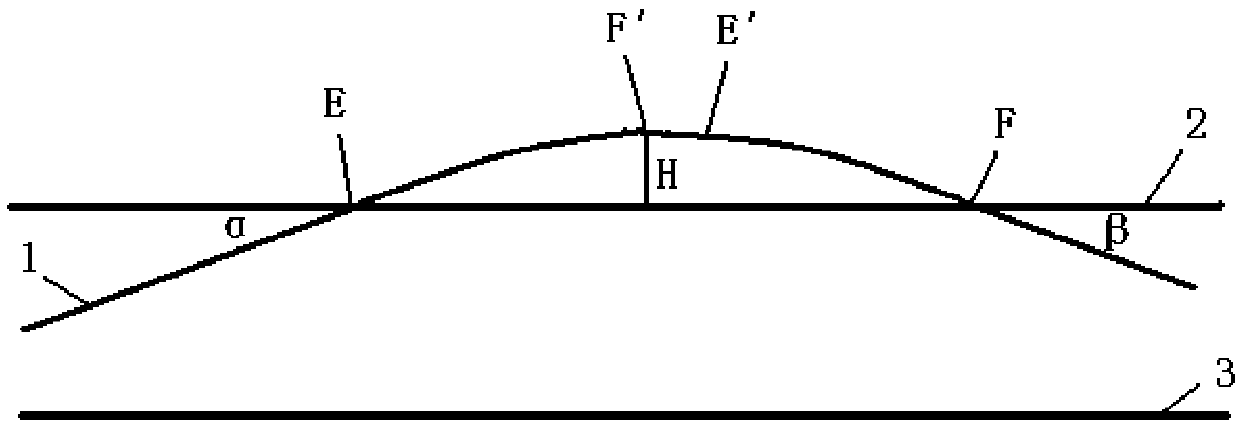

[0023] Such as figure 1 As shown, a method for selecting a chasing layer or sidetracking after the horizontal section of a coalbed methane horizontal well is released, includes the following steps:

[0024] 1) According to the data of drilling while drilling and adjacent wells, determine the layer-out direction, and calculate the layer-out angle difference α; Poor; preferred, β=3~4°, in this implementation, select β=3°;

[0025] Record the allowable maximum well inclination change rate b for every 10m in the horizontal section of the coal seam; adjust the well inclination to the footage required for the reverse angle difference β, that is, the directional adjustment section, and record the length of the directional adjustment section as EE′, EE′=10×( α+β) / b; preferably, b=2.5~3.5, during this implementation, selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com