Pipeline fixing structure

A technology for fixing structures and pipelines, applied to pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as increasing the cost of pipeline construction, and achieve the effect of saving time in setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

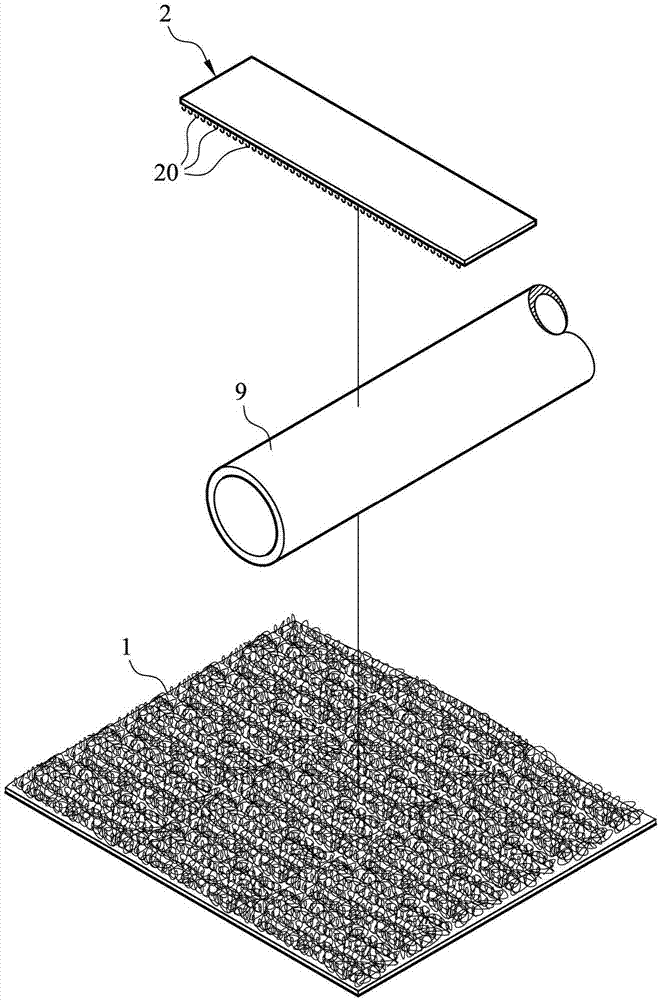

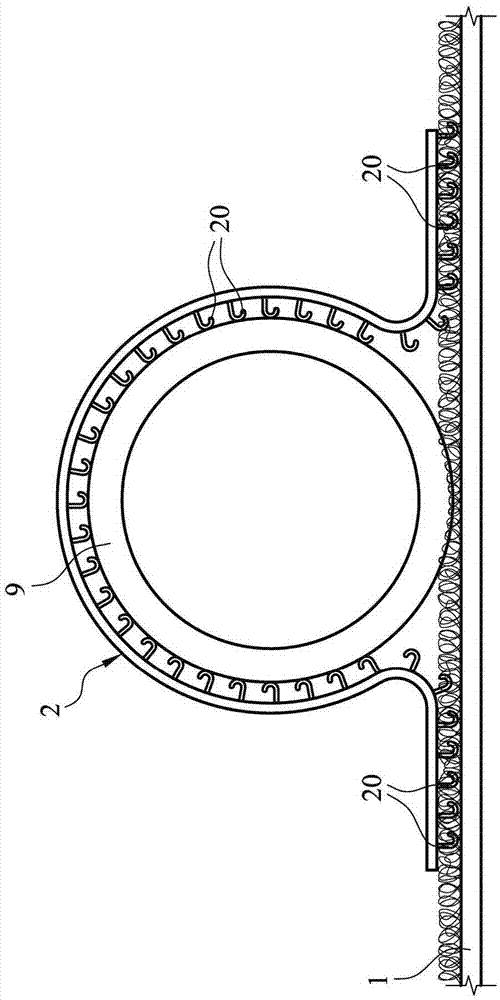

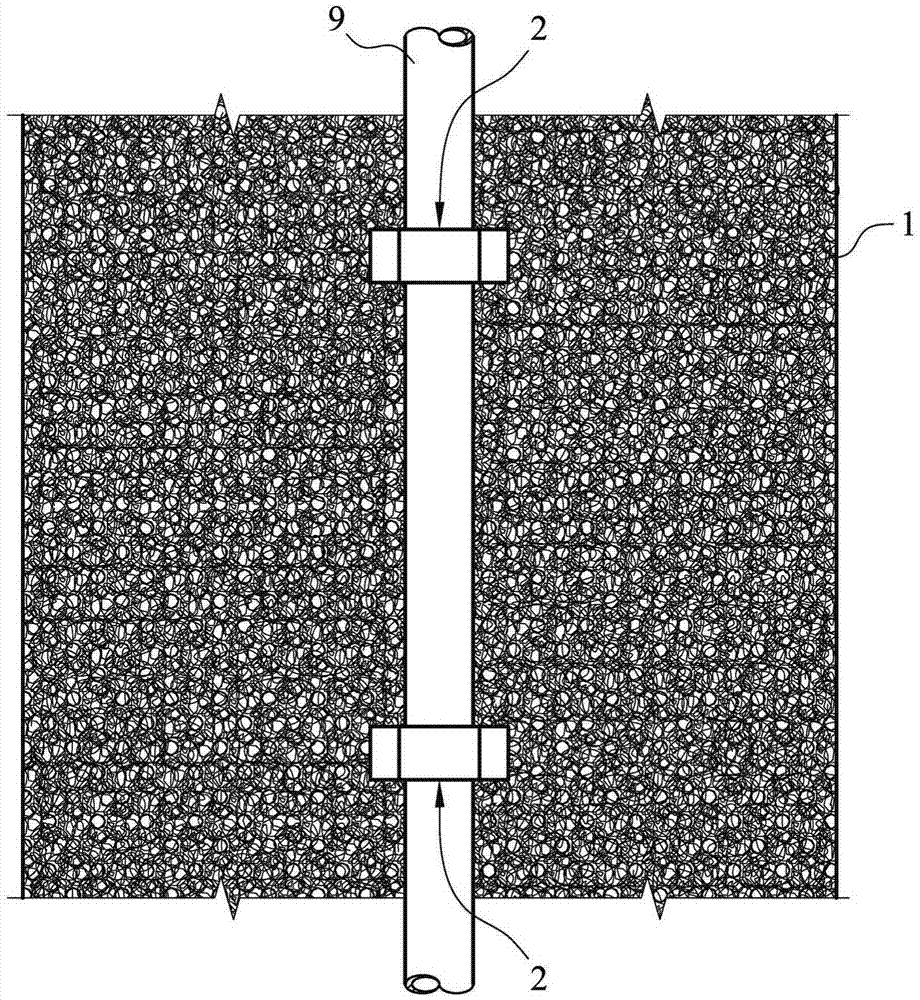

[0043] Figure 1 to Figure 3 A piping fixing structure according to a first embodiment of the present invention is shown.

[0044] Such as figure 1 As shown, the pipeline fixing structure according to the first embodiment of the present invention includes a substrate layer 1 and a fixing member 2 . The substrate layer 1 has a matte surface. The fixing member 2 is provided with a plurality of hooks 20 on one surface (first surface), and the hooks 20 can be mechanically fastened to the rough surface of the substrate layer 1 .

[0045] Next, the case of fixing the pipeline 9 in the floor heating system by means of the pipeline fixing structure according to the first embodiment of the present invention will be described. Firstly, the base material layer 1 is laid (fixed) on the ground in the predetermined range where the floor heating system is to be installed, and the pipeline 9 to be installed is placed on the base material layer 1 . Then, the central section of the fixing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com