A soi-based heterojunction thermally insensitive laser structure and fabrication method

A laser and heterojunction technology, applied in the field of lasers, can solve the problems affecting the development of optical modules, increasing the power consumption of optical modules, and inconvenient packaging, so as to facilitate integration and mass production, keep the optical wavelength stable, and reduce power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

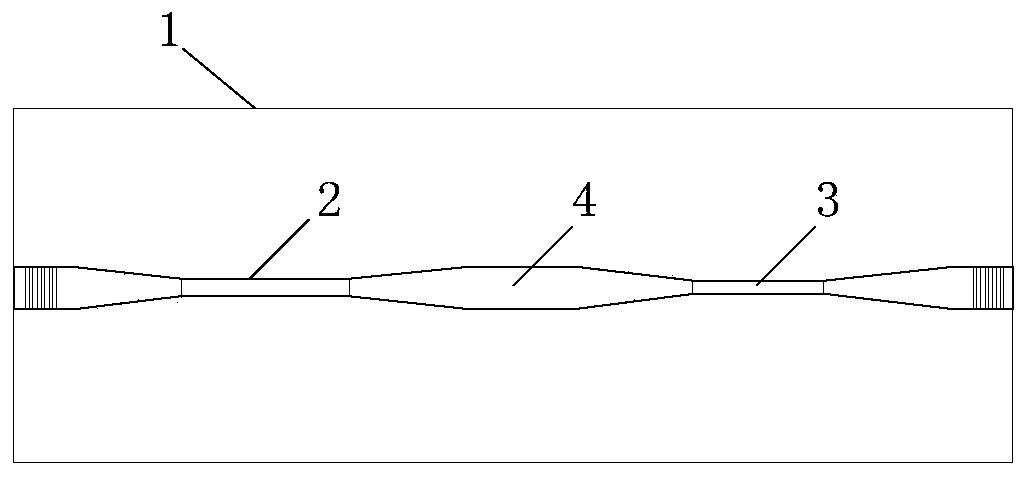

[0039] Embodiment 1 of the present invention provides a heterojunction thermally insensitive laser structure based on Silicon-On-Insulator (SOI for short), such as figure 1 As shown, it includes an SOI substrate 1, a waveguide in the active region of the III-V group, a polymer waveguide 3 with a negative temperature coefficient of refractive index, and a silicon waveguide 4. The polymer waveguide 3 and the silicon waveguide 4 are located on the SOI substrate 1, specifically:

[0040] The light outlet of the III-V group active region waveguide 2 is coupled to the light inlet of the silicon waveguide 4, and the light outlet of the silicon waveguide 4 is coupled to the light inlet of the polymer waveguide 3; the polymer The light exit port of the waveguide 3 is coupled with the light exit port of the laser.

[0041]The embodiment of the present invention can realize the thermal insensitivity of the laser, and when the temperature changes, the optical wavelength of the laser is s...

Embodiment 2

[0055] After proposing an SOI-based heterojunction heat-insensitive laser structure as described in Embodiment 1, the embodiment of the present invention further proposes a problem that can further improve the influence of temperature on the laser wavelength. Such as Figure 8 As shown, the laser proposed by the embodiment of the present invention includes an SOI substrate 1, a waveguide 2 in the active region of the III-V group, a polymer waveguide 3 with a negative refractive index temperature coefficient, a silicon waveguide 4, a first SiO2 waveguide 8 and a second SiO2 The waveguide 9, the waveguide 2 in the active region of the III-V group, the polymer waveguide 3 with a negative refractive index temperature coefficient, the silicon waveguide 4, the first SiO2 waveguide 8 and the second SiO2 waveguide 9 are located on the SOI substrate 1, specifically of:

[0056] The light outlet of the III-V active region waveguide 2 is coupled to the light inlet of the silicon wavegui...

Embodiment 3

[0065] The embodiment of the present invention also provides a method for fabricating an SOI-based heterojunction thermally insensitive laser, such as Figure 9 As shown, the method includes:

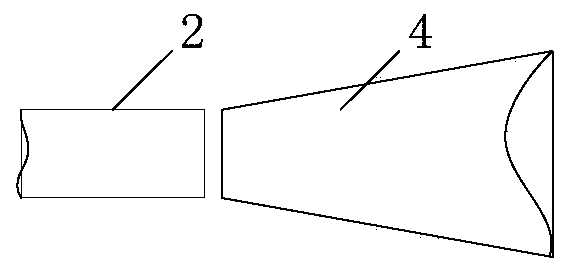

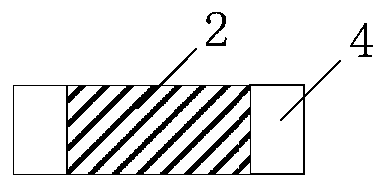

[0066] In step 201, a silicon waveguide 4 pattern is fabricated on the SOI substrate 1 by photolithography, wherein the light entrance and light exit of the silicon waveguide 4 pattern are respectively made into tapered shapes.

[0067] Wherein, the coupling combination between the light entrance of the silicon waveguide 4 and the light exit of the waveguide 2 in the III-V active region can adopt the following two methods.

[0068] method one:

[0069] Such as figure 2 and image 3 As shown, the light entrance of the silicon waveguide 4 is tapered, and the coupling between the III-V active region waveguide 2 and the tapered light entrance of the silicon waveguide 4 is completed. in, figure 2 is a schematic diagram of the enlarged local structure of the top view of the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com