A kind of soi hybrid integrated laser and its preparation method

A hybrid integration and laser technology, applied in the field of optical communication, can solve the problems of increasing the difficulty of packaging, the development trend of unfavorable device miniaturization, and limited packaging space, so as to reduce the packaging space of devices, benefit silicon photonics integration, Effect of Power Consumption Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

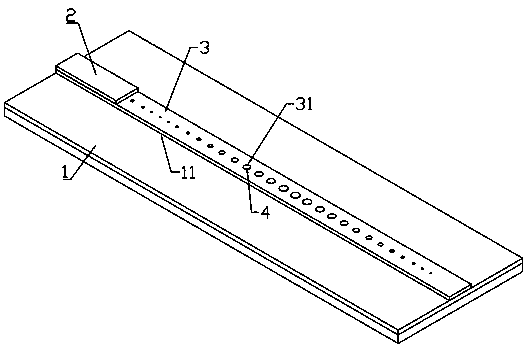

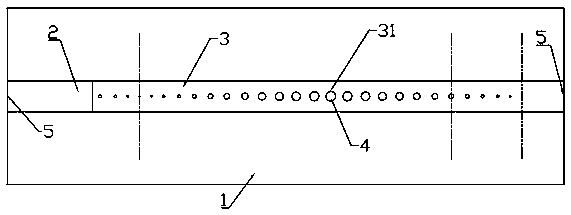

[0029] like Figure 1~2 As shown, an SOI hybrid integrated laser includes an SOI substrate 1, reflective structures 5 disposed opposite to each other on both sides of the SOI substrate 1 and used to form a reflective cavity, and a group III and V active region between the reflective structures 5 waveguide2.

[0030] Specifically, the reflection structure 5 is a reflection film or a reflection grating.

[0031] In the reflection structure 5, one of them has a reflection coefficient greater than 90%, and the other has a reflection coefficient of 43%~50%.

[0032] The silicon waveguide layer 11 on the top layer of the SOI substrate 1 forms a one-dimensional photonic crystal waveguide 3 through exposure, development and etching, so as to realize the coupling and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com