Sliding table locking mechanism

A technology of locking mechanism and sliding table, which is applied in the direction of clamps, manufacturing tools, etc., can solve the problems of remote locking and other problems, and achieve the effect of overcoming the need to manually adjust the locking screw, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

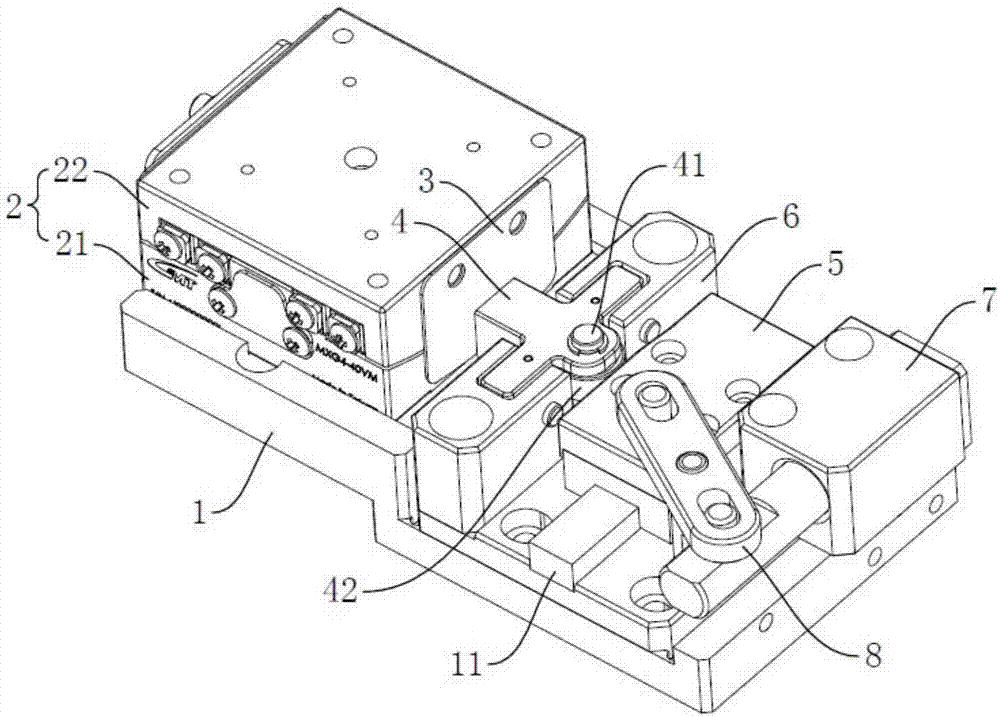

[0023] Combine below Figure 1 to Figure 4 And further illustrate the technical solution of the present invention through specific examples.

[0024] Such as Figure 1 to Figure 4 As shown, the sliding table locking mechanism includes a fixed plate, which is provided with a sliding table and a force applying mechanism for locking the slide table. The slide table is provided with a brake pad, and the force applying mechanism includes a brake push block and a force applying mechanism for pushing the slide table. The brake push block is used to lock the wedge of the brake pad, and both the brake push block and the wedge are slidably connected with the fixed plate.

[0025] When the wedge moves relative to the fixed plate under the action of external force, the brake pusher is pressed by the wedge, and under the force of the wedge, it moves toward the brake pad and squeezes the brake pad, so that the brake pad is in contact with the brake pad. The slide table fits tightly to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com