Novel packaging lined paper device for cigarette products

A new type of packaging and lining paper technology, applied in packaging, cigarette packaging, transportation and packaging, etc., can solve the problems of inconsistent forming effect, low production efficiency, and inability to realize automatic production, so as to achieve uniform forming effect and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

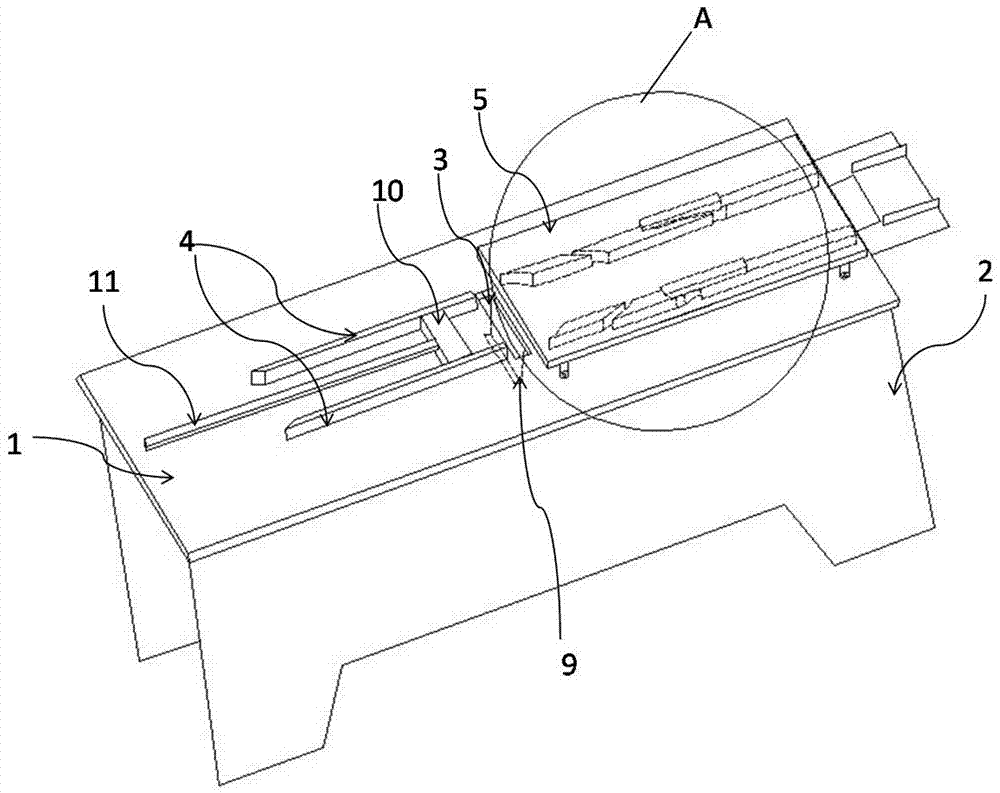

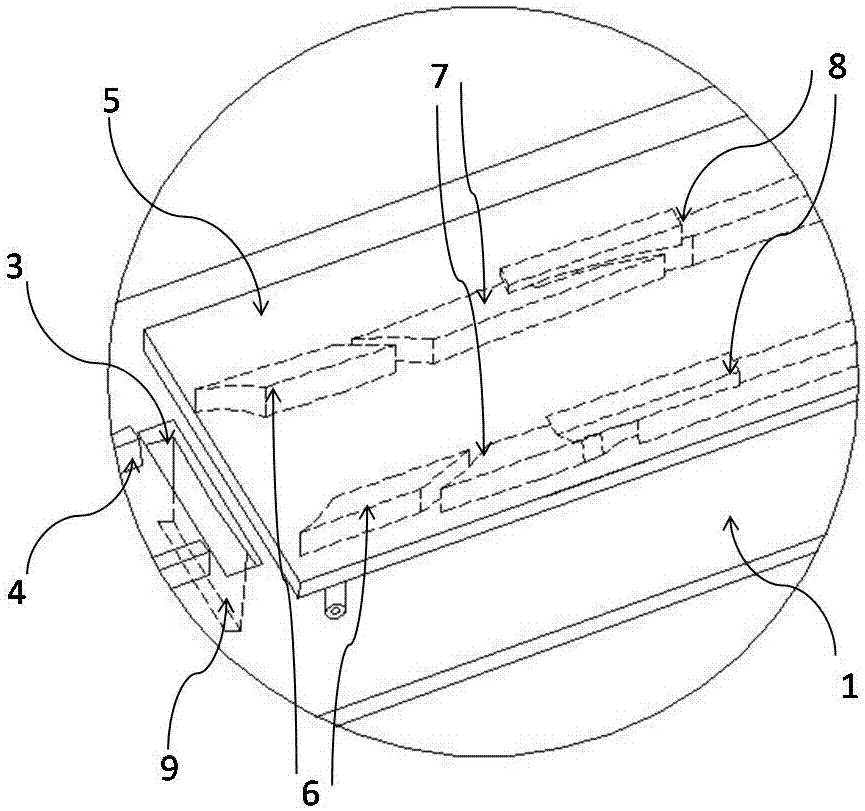

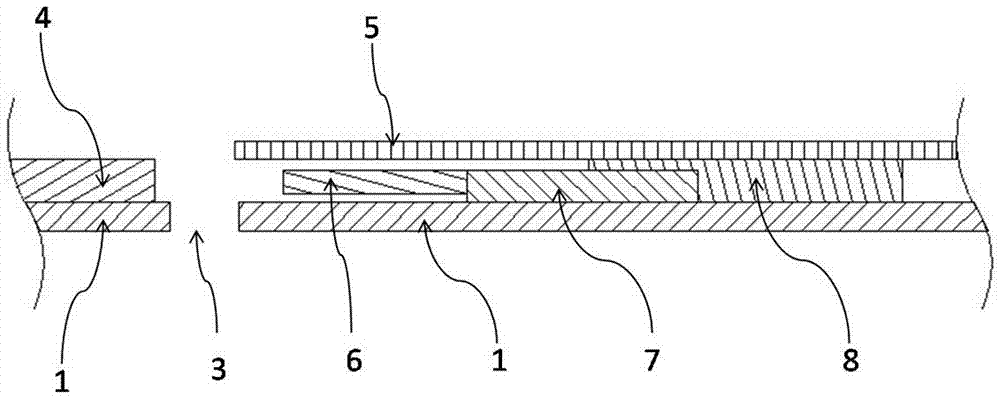

[0041] Such as Figure 1~4 As shown, a device for a new type of packaging inner lining paper for cigarette products, including a base plate 1, a bracket 2 for supporting the base plate 1, an opening 3 provided on the base plate for the inner lining paper to pass through, a cigarette group arrangement mechanism, and The lining paper placement mechanism for placing the lining paper at the opening, the folding mechanism for folding the lining paper, and the driving mechanism;

[0042] The cigarette group arrangement mechanism includes a first guide rail 4, a cigarette pushing plate 10 arranged on the bottom plate 1 and used to push the cigarette group to move, the first guide rail 4 is arranged on both sides of the cigarette pushing plate to form a first passage for the cigarette group to move, The first channel is located on one side of the opening 3 .

[0043] The folding mechanism includes a first baffle 5 , a second guide rail 6 , a third guide rail 7 and a fourth guide rail...

Embodiment 2

[0055] This embodiment is the second embodiment of the present invention, different from Embodiment 1, as Figure 5 as shown,

[0056] The lining paper placement mechanism also includes a lower paper guide 12 arranged on the first baffle 5 , and both sides of the lower paper guide 12 are provided with retaining bars 1201 to prevent the inner lining from falling over.

[0057] Other components and their connections are the same as in Embodiment 1.

Embodiment 3

[0059] This embodiment is the third embodiment of the present invention, different from Embodiment 2, as Figure 6~7 as shown,

[0060] The driving mechanism also includes a smoke pushing guide plate 13 arranged below the bottom plate. The bottom plate is provided with a first guide bar hole 14 . The bracket is provided with a second guide bar hole 15, the smoke pushing guide plate passes through the second guide bar hole 15 and is connected with the handle 11, the smoke pushing guide plate is provided with a pulley 16 located at the second guide bar hole 15, and the push handle 11 is pushed to drive the pusher. The smoke plate 10 moves.

[0061] A second baffle 17 is provided above the bottom plate 1 at the first channel, and the distance between the second baffle 17 and the bottom plate 1 matches the height of the cigarette group to level the cigarette group. The first guide rail can be composed of a first section and a second section close to the opening, the distance bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com