Big bone-shaped baked bun furnace

A furnace body and hearth technology, which is applied in the field of special stoves for making big bone buns, can solve the problem of not being able to make white big bone buns and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

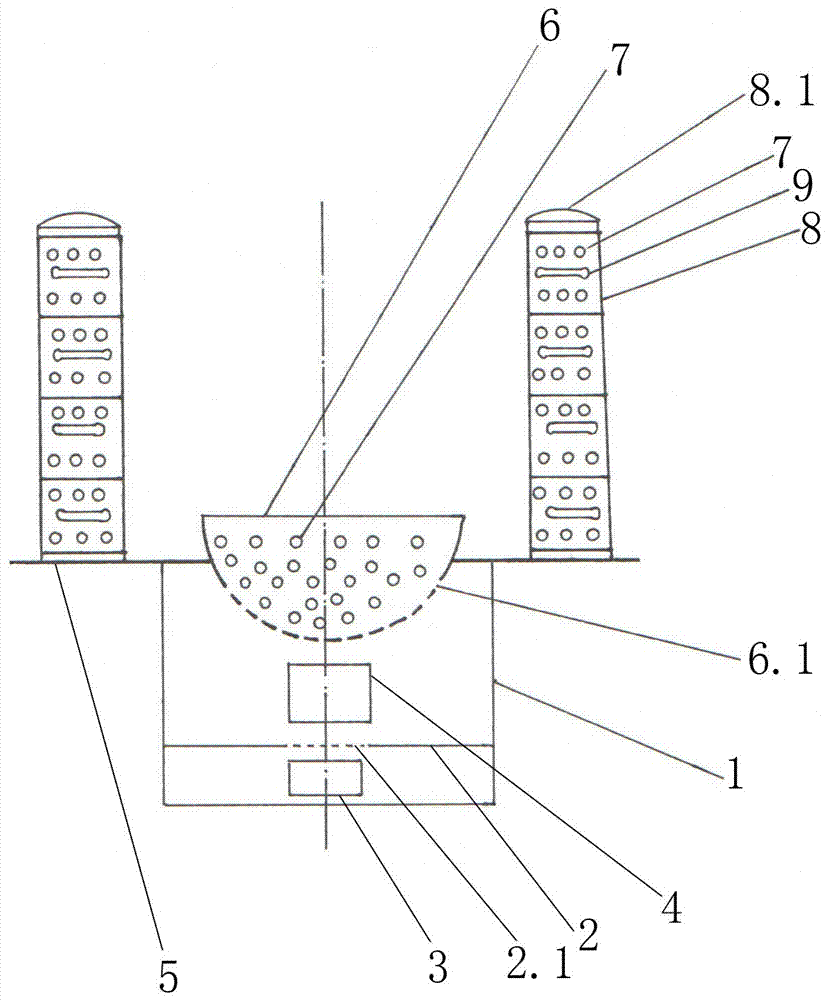

[0010] The specific structure of the big bone steamed bun stove of the present invention will be described in detail below in conjunction with accompanying drawings.

[0011] exist figure 1 Among them, the big bone steamed bun furnace provided by the present invention is composed of a furnace body, a furnace bottom, a damper, a furnace hearth, a furnace door, a furnace top, a steamer cage, sand rice, and an iron pot. It is characterized in that: the furnace body (1) There is a damper (3) in the lower part, and above the damper (3) is the furnace bottom (2), and the center of the furnace bottom (2) is a kiln with a grate (2.1), and the combustion material in the kiln is charcoal, coke or For anthracite, there is a furnace door (4) in the middle of the furnace body (1), and the interior of the furnace body (1) is a cylindrical furnace, above which is the furnace roof (5), and there are several Warm cage base, multi-layered warm cages (8) are stacked on the warm cage base, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com