Anti-seismic steel support for bridge

A technology of anti-seismic steel and bridges, which is applied in the direction of bridges, bridge parts, bridge construction, etc., and can solve the problem of single function and scope of application of anti-seismic bearings, and the bearings are prone to tension, poor tensile capacity or anti-vertical lift-off ability and other problems, to achieve strong anti-vertical lift-off ability, reduce beam end collision damage, and greatly promote the effect of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

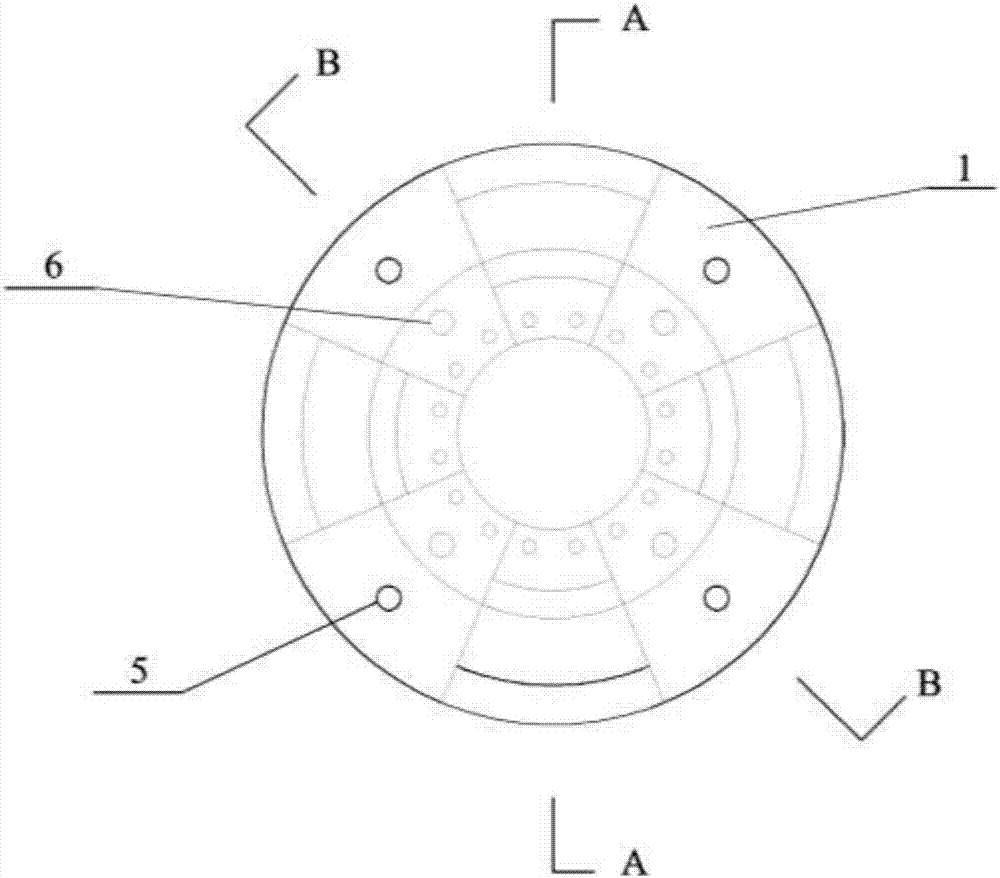

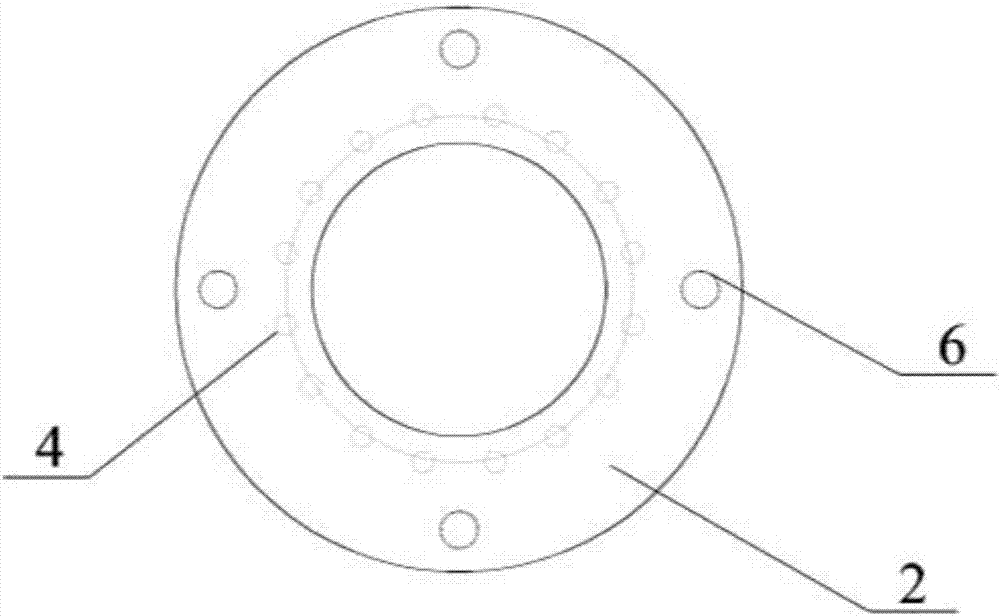

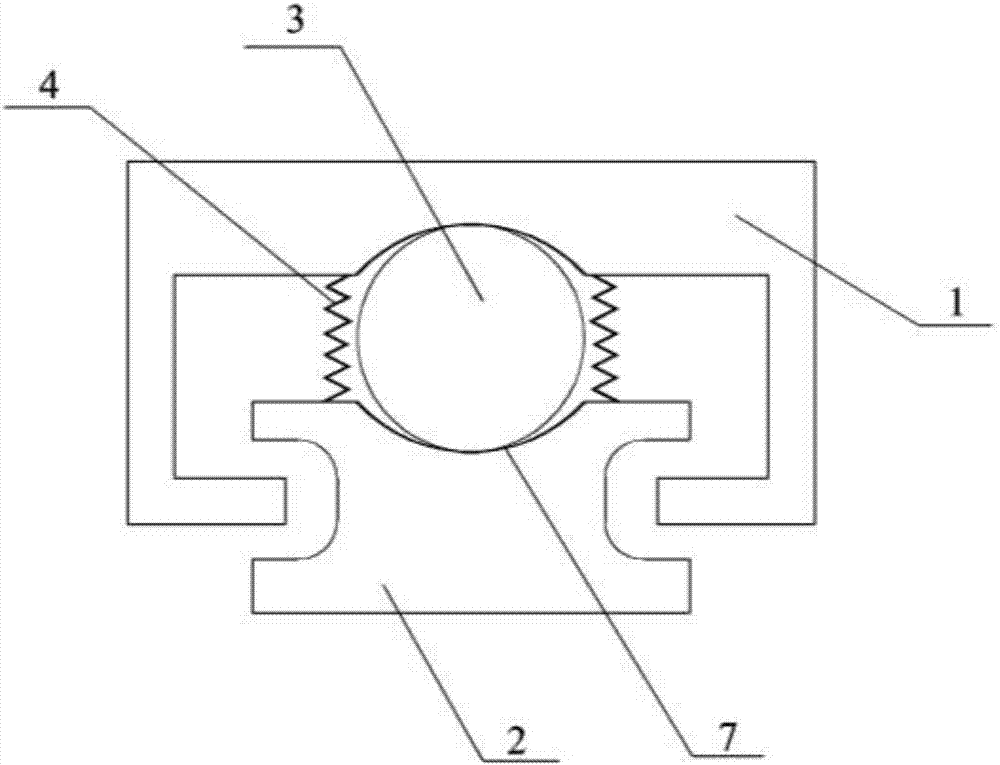

[0022] like Figure 1-4 As shown in the figure, an anti-seismic steel bearing of a bridge includes an upper bearing body 1 connected with the main beam of the bridge and a lower bearing body 2 connected with the bridge cover beam or pier; it also includes a steel sphere 3, which is arranged on the upper bearing between the body 1 and the lower support body 2; the upper support body 1 is provided with a concave arc-shaped upper connecting portion that matches the rigid sphere 3 at the position corresponding to the steel ball 3, and the lower support body 2 is provided at the position corresponding to the steel ball 3 There is a concave arc-shaped lower connecting part that matches the rigid ball 3; a spring 4 is arranged between the upper support body 1 and the lower support body 2, which can move relatively; the surfaces of the upper connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com