A multi-segment hip joint

A hip joint, multi-segment technology, applied in the directions of hip joint, joint implants, joint implants, etc., can solve the problem of not meeting the functional requirements of bionic artificial bone, uneven performance of multi-level porous materials, and reports of multi-level porous materials. limited and other problems, to achieve good structural mechanical properties, accelerated healing effect, and improved penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

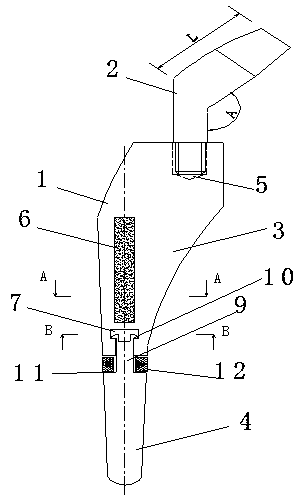

[0029] As attached to the manual Figure 1-4As shown, a multi-segment hip joint includes a femoral stem 1, a femoral neck 2 and a cushion 12; the femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the upper end surface of the head of the proximal end 3 A mounting hole 5 is provided, and the mounting hole 5 is specifically set as a threaded hole; the lower part of the femoral neck 2 is in the shape of a positive cylinder as a whole, the upper part is set as an offset inclined column, and the lower end of the femoral neck 2 is set as a threaded rod; the threaded rod It is directly matched and connected with the mounting hole 5; the middle part of the proximal end 3 of the femoral stem 1 is provided with a filling interlayer 6 made of multi-level hole material that runs through both sides of the handle body; the lower part of the proximal end 3 is provided with an inner hole 7, the inner hole 7 is provided with four discontinuously distributed steppe...

Embodiment 2

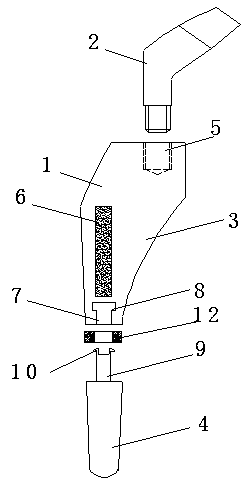

[0041] As attached to the manual Figure 5-6 As shown, a multi-segment hip joint includes a femoral stem 1, a femoral neck 2 and a cushion 12; the femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the upper end surface of the head of the proximal end 3 There is a mounting hole 5; the lower part of the femoral neck 2 is in the shape of a positive cylinder as a whole, and the upper part is set as an offset inclined column, and the lower part of the femoral neck 2 is directly installed in the mounting hole 5 through an interference fit; the proximal end of the femoral stem 1 is 3 The middle part is provided with a filling interlayer 6 made of a multi-stage porous material that runs through both sides of the handle body; the lower part of the proximal end 3 is provided with an inner hole 7, and the inner hole 7 is provided with two discontinuously distributed stepped surfaces 8; A connecting rod 9 is added on the head of the end 4, and the end of the...

Embodiment 3

[0053] As attached to the manual Figure 7 As shown, a multi-segment hip joint includes a femoral stem 1 and a femoral neck 2; the femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the upper end surface of the head of the proximal end 3 is provided with a mounting hole 5. The mounting hole 5 is specifically set as a threaded hole; the lower part of the femoral neck 2 is in the shape of a positive cylinder as a whole, the upper part is set as an offset inclined column, and the lower end of the femoral neck 2 is set as a threaded rod; the threaded rod and the mounting hole 5 Direct fit connection; the middle part of the proximal end 3 of the femoral stem 1 is provided with a filling interlayer 6 made of multi-level porous material that runs through both sides of the handle body; the lower part of the proximal end 3 is provided with an inner hole 7, and the inner hole 7 is provided with Four discontinuously distributed step surfaces 8; the head of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com