A Cushioned Hip

A hip joint and hole cavity technology, applied in hip joints, joint implants, joint implants, etc., can solve problems such as uneven mechanical strength, elastic modulus, impact on function, hidden quality problems, etc., and achieve good structural mechanics. performance, slowing down severe impact, avoiding the effect of failure and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

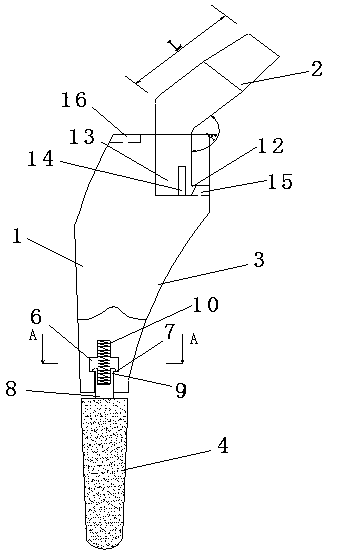

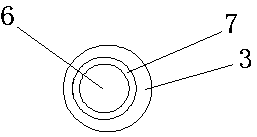

[0031] As attached to the manual Figure 1-3As shown, a cushioning hip joint includes a femoral stem 1, a femoral neck 2 and a spring 10; its femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the head of the proximal end 3 is provided with L-shaped through hole 5, and the head of proximal end 3 is provided with positioning hole 16; One part is a barb 12, the other part is a columnar body 13, and a gap 14 is provided between the barb 12 and the columnar body 13; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 5, and the barb 12 is hooked in the transverse hole 15 on the L-shaped through hole 5; the lower part of the proximal end of the femoral stem 1 is provided with an inner hole 6, and the middle cavity of the inner hole 6 is a cylinder, and the inner diameter of the middle cavity is larger than the inner diameter. The maximum inner diameter of the upper and lower cavities of the hole 6, the end of the cylindrica...

Embodiment 2

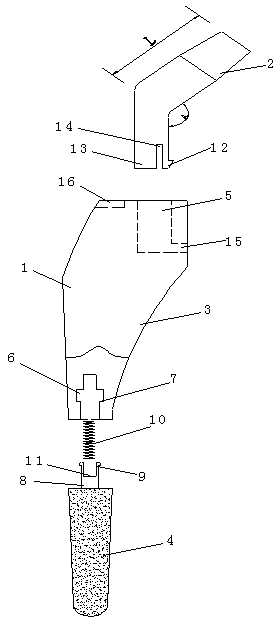

[0043] As attached to the manual Figure 4-5 As shown, a cushioning hip joint includes a femoral stem 1, a femoral neck 2 and a spring 10; its femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the head of the proximal end 3 is provided with L-shaped through hole 5; the lower part of the femoral neck 2 is in the shape of a positive column as a whole, and the upper part is set as an offset inclined column; the lower end of the femoral neck 2 is composed of two parts, one part of which is a barb 12, and the other part is a columnar body 13, and a gap 14 is provided between the barb 12 and the columnar body 13; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 5, and the barb 12 is hooked into the transverse hole 15 on the L-shaped through hole 5 Inside; the lower part of the proximal end of the femoral stem 1 is provided with an inner hole 6, and two symmetrically distributed discontinuous stepped surfaces 7 are arrange...

Embodiment 3

[0054] As attached to the manual Image 6 As shown, a cushioning hip joint includes a femoral stem 1 and a femoral neck 2; the femoral stem 1 is split into two parts, the proximal end 3 and the distal end 4; the head of the proximal end 3 is provided with an L-shaped through hole 5; the lower part of the femoral neck 2 is in the shape of a positive column as a whole, and the upper part is set as an offset inclined column; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 5 through interference fit; the proximal end of the femoral stem 1 The lower part is provided with an inner hole 6, which is provided with a continuous annular stepped surface 7; its distal end 4 is made of a multi-stage porous material, and a connecting rod 8 is added on the head of the distal end 4, and the connecting rod 8 is connected The end of the rod 8 has an elastic barb 9; the connecting rod 8 is inserted into the inner hole 6, and the elastic barb 9 is hooked at the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com