A combined hip joint

A hip joint, combined technology, used in hip joints, joint implants, joint implants, etc., can solve problems such as uneven distribution of elastic modulus, uneven distribution of voids, and limited, and achieve good structural mechanical properties. , reduce rejection and enhance the effect of efficient exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

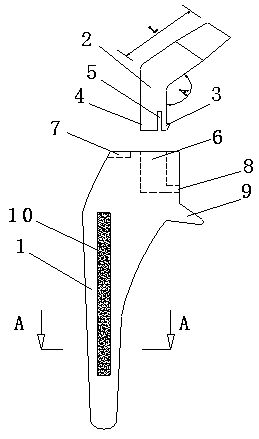

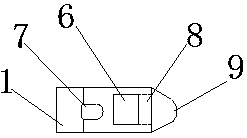

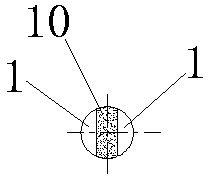

[0029] As attached to the manual Figure 1-3As shown, a combined hip joint includes a femoral stem 1 and a femoral neck 2; the lower part of the femoral neck 2 is in the shape of a positive column as a whole, and the upper part is set as an offset inclined column; the lower end of the femoral neck 2 is composed of two Composed of parts, one part is an elastic barb 3, the other part is a columnar body 4, and there is a gap 5 between the elastic barb 3 and the columnar body 4; the head of the femoral stem 1 is provided with an L-shaped through hole 6 , and the upper end of the head is also provided with a positioning hole 7; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 6, and the elastic barb 3 is hooked in the transverse hole 8 on the L-shaped through hole 6; its femoral stem 1 A tapered protrusion 9 is provided on the side close to the femoral neck 2 in the middle part, and the middle part of the femoral stem 1 is also provided with a filling...

Embodiment 2

[0041] As attached to the manual Figure 4 As shown, a combined hip joint includes a femoral stem 1 and a femoral neck 2; the lower part of the femoral neck 2 is in the shape of a positive column as a whole, and the upper part is set as an offset inclined column; the lower end of the femoral neck 2 is composed of two Composed of parts, one part is an elastic barb 3, the other part is a columnar body 4, and there is a gap 5 between the elastic barb 3 and the columnar body 4; the head of the femoral stem 1 is provided with an L-shaped through hole 6 , and the upper end of the head is also provided with a positioning hole 7; the lower part of the femoral neck 2 is inserted into the L-shaped through hole 6, and the elastic barb 3 is hooked in the transverse hole 8 on the L-shaped through hole 6; its femoral stem 1 The middle part of the handle body is also provided with a filling interlayer 10 made of a multi-level porous material that runs through both sides of the handle body; i...

Embodiment 3

[0052] As attached to the manual Figure 5 As shown, a combined hip joint includes a femoral stem 1 and a femoral neck 2; the lower part of the femoral neck 2 is in the shape of a positive column as a whole, and the upper part is set as an offset inclined column; the lower end of the femoral neck 2 is composed of two Composed of parts, one part is an elastic barb 3, the other part is a columnar body 4, and there is a gap 5 between the elastic barb 3 and the columnar body 4; the head of the femoral stem 1 is provided with an L-shaped through hole 6 The lower part of the femoral neck 2 is inserted into the L-shaped through hole 6, and the elastic barb 3 is hooked into the transverse hole 8 on the L-shaped through hole 6; The filling interlayer 10 made of a hierarchical porous material; the hierarchical porous material used in the filling interlayer 10 in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com