Capacitor discharging tool

A capacitor and tool technology, applied in the direction of circuits, electrical components, conductive connections, etc., can solve the problem that the discharge tool cannot meet the discharge requirements, and achieve the effect of changing the direction of the discharge operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

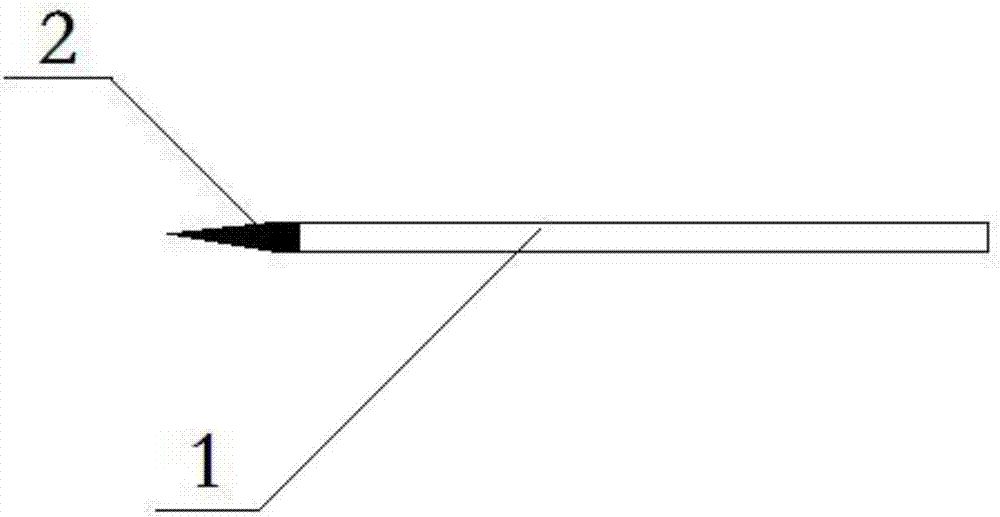

Embodiment 1

[0041] Embodiment 1, intensive capacitor discharge application: after entering the capacitor bank, perform touch discharge operations on various equipment around you in sequence. For dense capacitors, an insulating sheath will generally be added to the pile head of the casing in the later stage to prevent short-circuit faults between phases of small animals. Just discharge it.

Embodiment 2

[0042] Embodiment 2, the discharge application of the frame type capacitor bank: only the hook-like part 7 of the present invention hooks one of the first stages of the capacitor lightly, and gently pushes along the trend, and under the action of the spring, the metal grounding rod 3 and the insulating operating rod 2 An angle is formed between them to ensure that the entire metal grounding rod 3 is in contact with the two stages of the capacitor to meet the requirements of single-stage and phase-to-phase discharge of the capacitor, and to discharge multiple times one by one according to the regulations. Figure 8 It is a schematic diagram of the use state of the elastic connector of the present invention when the bend is less than 90 degrees. In the figure, A is the use state of the elastic connector when it is bent at 0 degrees, and B is the elastic connector when the bend is greater than 0 degrees and less than The use state at 90 degrees, Figure 9 It is a schematic diagra...

Embodiment 3

[0043] Embodiment 3, the application of the discharge at the central point of the capacitor bank: there is no phase-to-phase discharge in the discharge at the central point, and you only need to hold the present invention in your hand and operate it at any position.

[0044] The present invention designs and installs a spring between the metal grounding rod 3 and the insulating operating rod 2, through the bending angle and recoverability of the spring, it can meet the operation requirements that the operator can easily discharge when standing at any position, and can simultaneously Ground and phase-to-phase discharge operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com