Soil pushing device special for spiral

A technology of soil scraper and screw, applied in the field of screw special soil scraper, can solve problems such as waste of power resources, waste of resources, delay of time, etc., and achieve the effect of reducing waste of human resources, improving work efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but this does not constitute any limitation to the present invention.

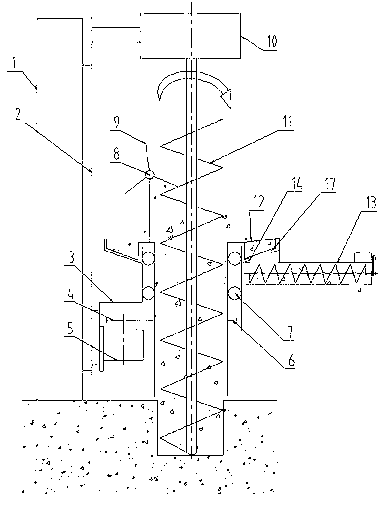

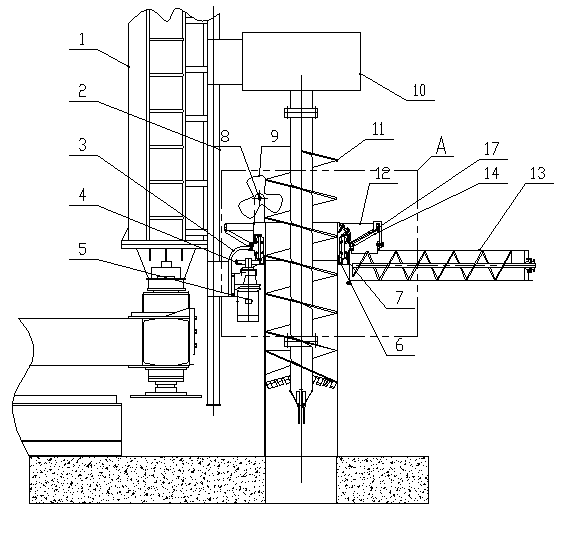

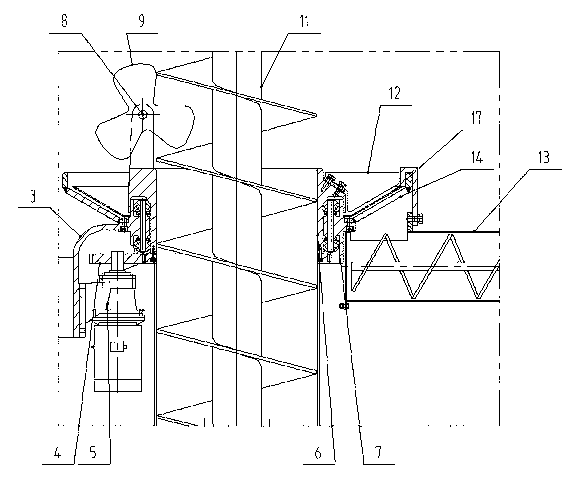

[0033] Such as figure 1 , figure 2 shown, and refer to image 3 , a screw special soil mover, the body 3 of the soil mover is located on the guide rail 2 of the pile driver frame; the reducer II 10 drives the drill pipe 11 to rotate forward, reverse and move up and down; the soil mover has a rotary body 6, which rotates The driving element of the body 6 is a motor (not shown in the figure) and is provided with a reducer I5, and the reducer I5 is located on the body 3 of the earth mover; a gear pair is formed by the teeth on the input gear 4 and the rotary body 6, and the motor 1. The speed reducer I5 rotates the rotary body 6 through the teeth on the input gear 4 and the rotary body 6. The center of the rotary body of the rotary body is located on the axis of the drill rod of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com