Adjustable sieve mesh mechanism of feed hopper of threshing machine

A hopper-feeding, adjustable technology, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., can solve problems such as difficult operation, high cost, and poor adaptability to work, and achieve simple and convenient adjustment, good performance, and adaptability powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

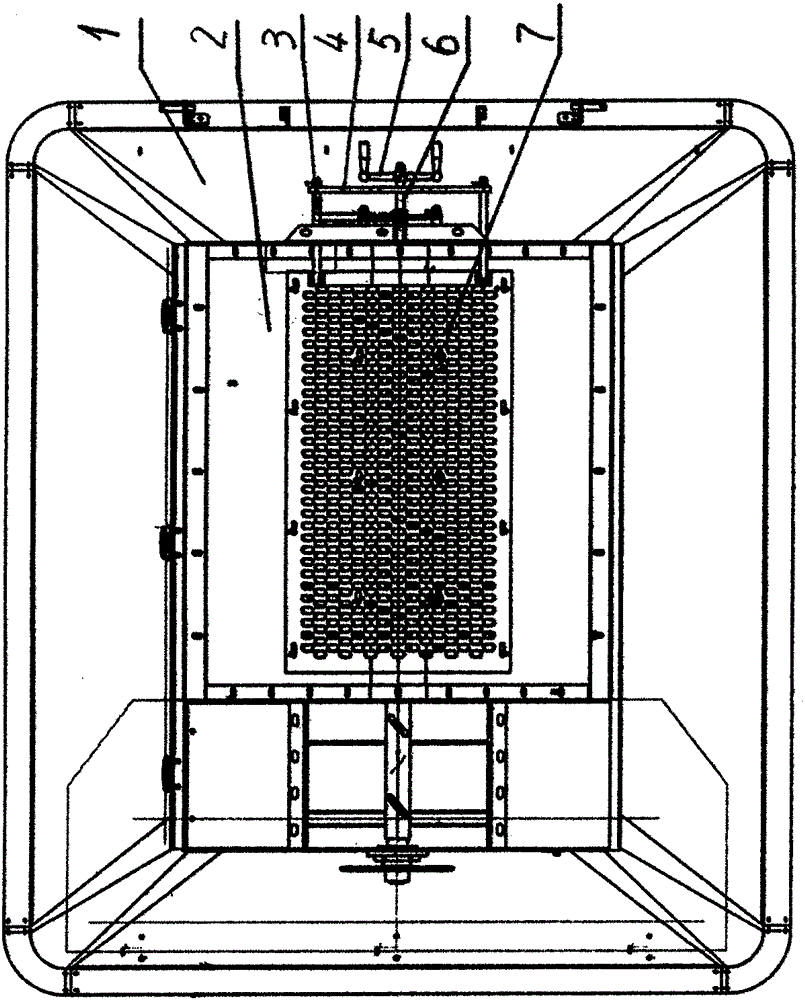

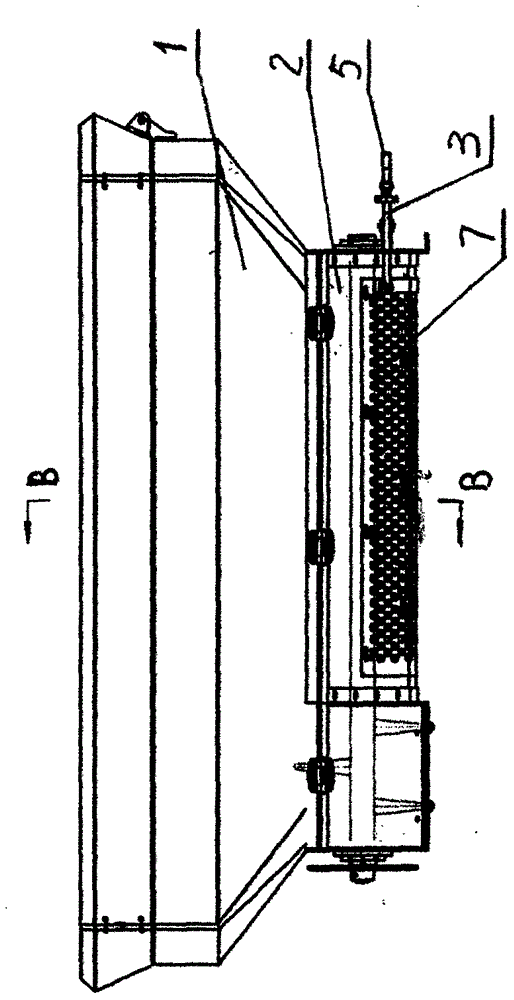

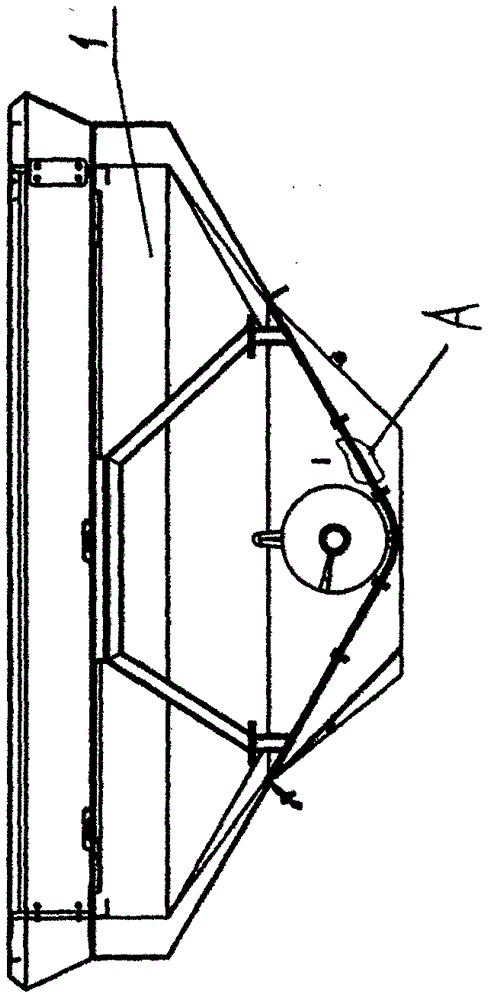

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An adjustable sieve mechanism for a hopper of a thresher includes a hopper 1 and a V-shaped fixed sieve 2 with a fixed sieve hole 8. The V-shaped fixed sieve 2 is fixed on the bottom of the hopper 1. The bottom side of the V-shaped fixed sieve 2 is covered by the outer upper cover and can be adjusted and moved horizontally. It is equipped with a V-shaped movable sieve 7 with a movable sieve hole 9. The movable sieve hole 9 and the fixed sieve hole 8 form a Overlapping or shielding and covering cooperation, a tie rod 3 is fixed on one side of the V-shaped moving screen 7, and the screw rod 6 is axially and radially positioned and circumferentially rotatable installed on the outside of the bottom side of the feeding hopper 1, so that The screw rod 6 and the pull rod 3 are parallel to each other, and the nut plate 4 is axially movable on the screw rod 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com