Labeling mechanism

A labeling and coding technology, applied in labeling machines, labels, packaging, etc., can solve the problems of low production quality, non-standard operation, low productivity, etc., to reduce production costs, improve coding quality, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing and embodiment:

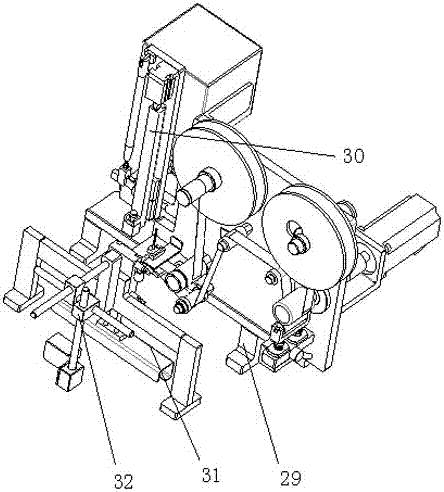

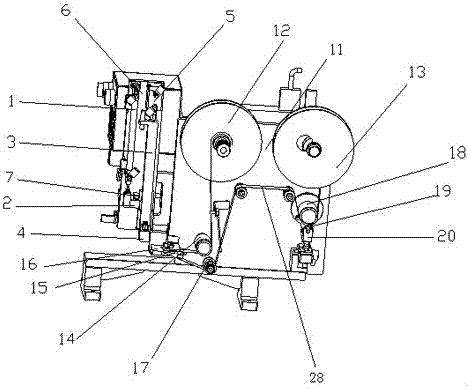

[0028] like Figure 1-4 As shown, a labeling mechanism includes a code sticking device 30, a correcting device 31 and a scanning device 32. The code sticking device 30 is distributed in parallel with the correcting device 31, and the scanning device 32 is located On the device 31;

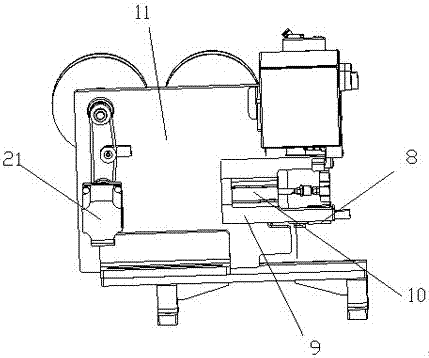

[0029] The code sticking device 30 includes a base bracket 29, a glue plate 6, a connecting bracket 2, a suction block fixing seat 3, a suction block 4, a linear guide rail 8, a guide rail fixing seat 9, a first cylinder 1, a second cylinder 5, The third cylinder 10, vertical plate 11, unwinding reel 12, rewinding reel 13, first crossing stick 14, second crossing stick 17, rotating shaft fixing seat 15, suction glue support 16, traction shaft 18, pressure roller 19, can Regulator 20 and motor 21;

[0030] The base support 29 is provided with the glued plate 6 and the vertical plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com