High-energy optical fiber cutter

A cutting knife and optical fiber technology, applied in the direction of optical waveguide coupling, etc., can solve the problems of increasing optical fiber detection cost and reducing production efficiency, and achieve the effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

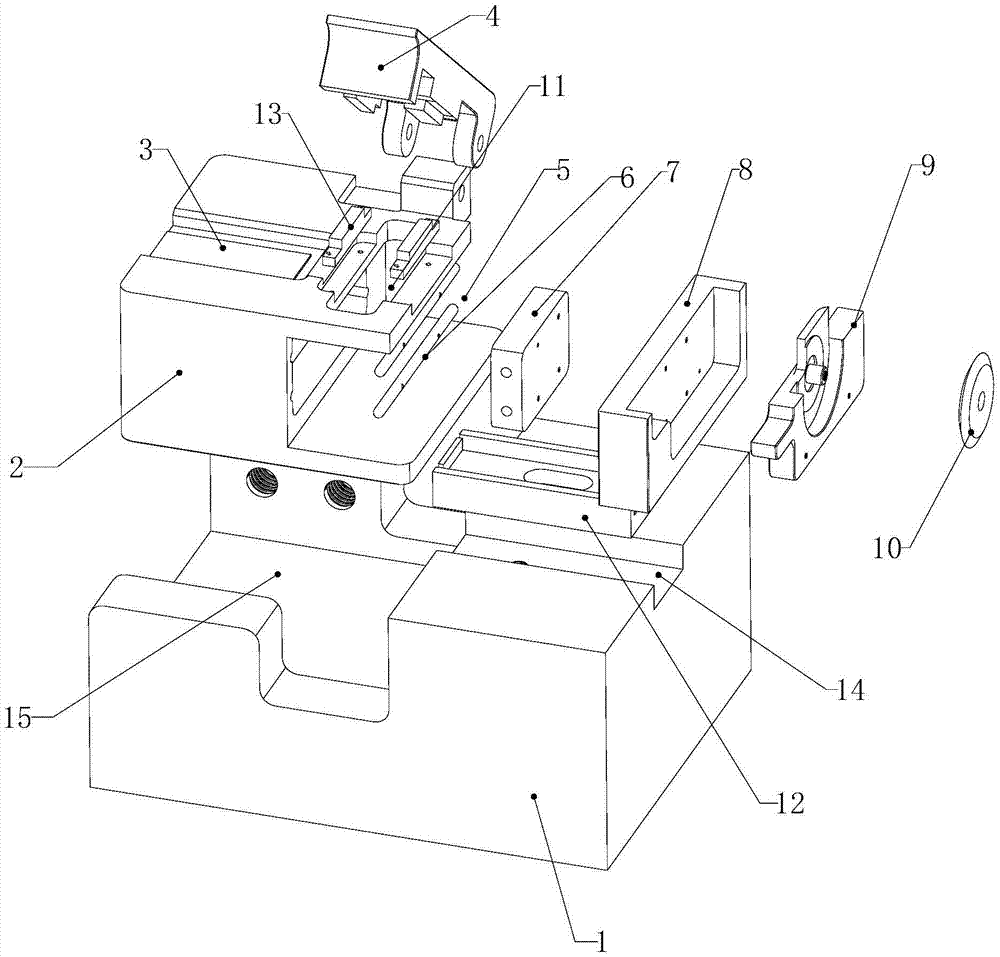

[0014] see figure 1 , a high-energy fiber optic cutter in a preferred embodiment of the present invention, comprising a base 1, a base 2 is fixedly arranged on the base, an optical fiber guide groove 3 is arranged on the base, and a cover plate 4 is hingedly arranged on one side of the base , the base below the cover plate is provided with a cutting groove 5, a cutting device is arranged in the cutting groove, the cutting device includes a slider guide rail 6 and a slider 7 arranged on the slider guide rail, and a knife holder seat is fixedly arranged on the slider 8. A knife rest 9 is arranged on the knife rest seat, and a cutting knife 10 is rotatably arranged on the kn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap