Rod end open groove cold heading die

A technology of open groove and cold heading, which is used in manufacturing tools, mechanical equipment, engine components, etc., can solve problems such as difficulty in ensuring the quality of open grooves, upsetting, and inability to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

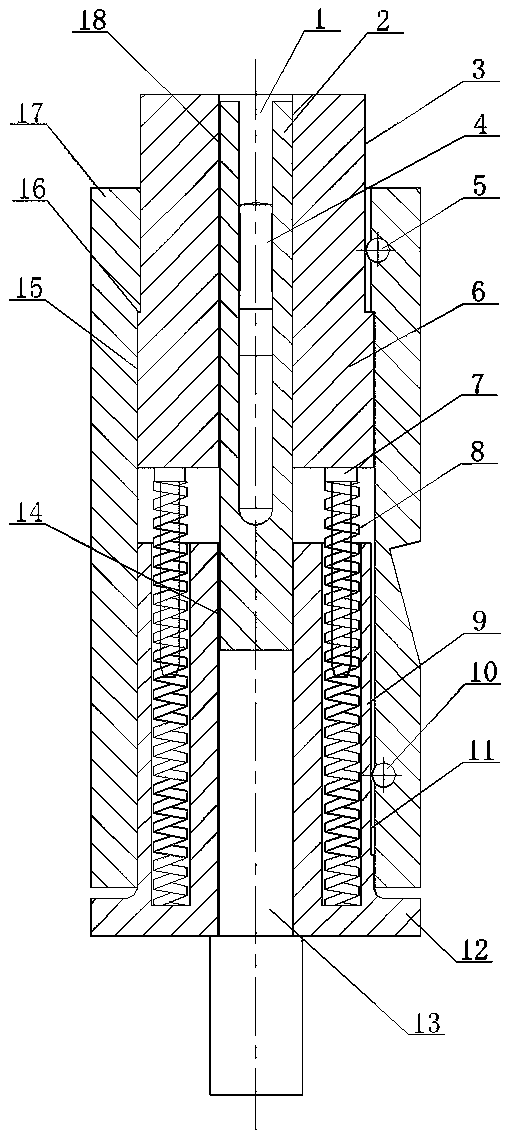

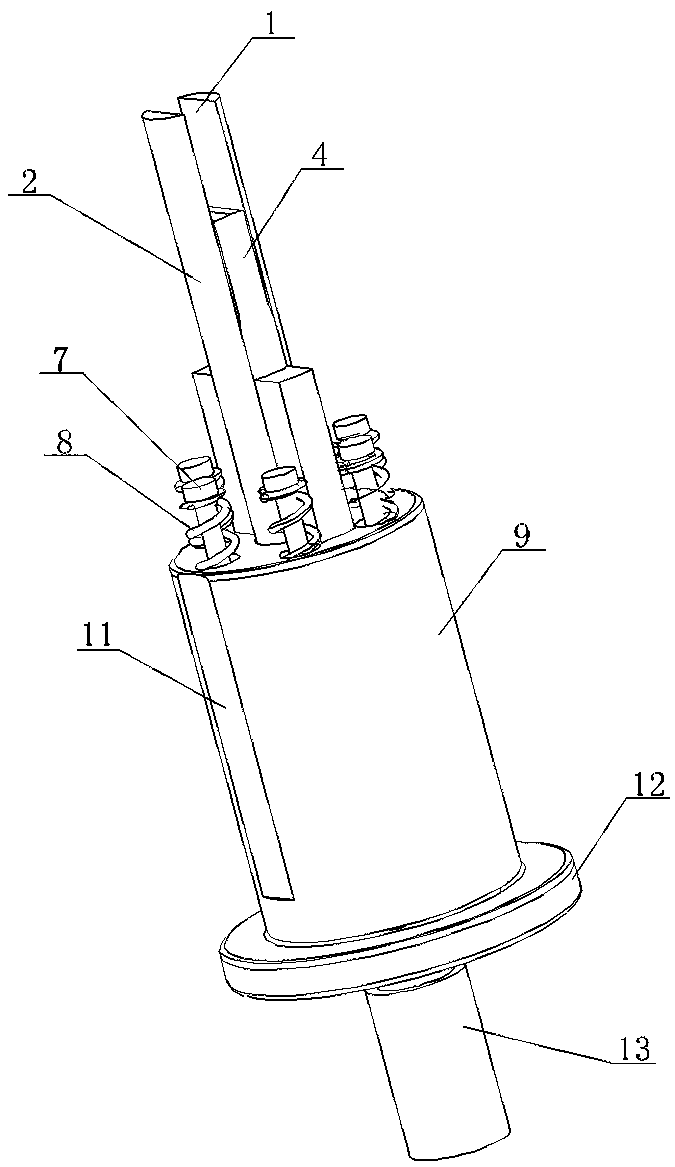

[0016] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details and working principles of the embodiments will be further described below in conjunction with the accompanying drawings.

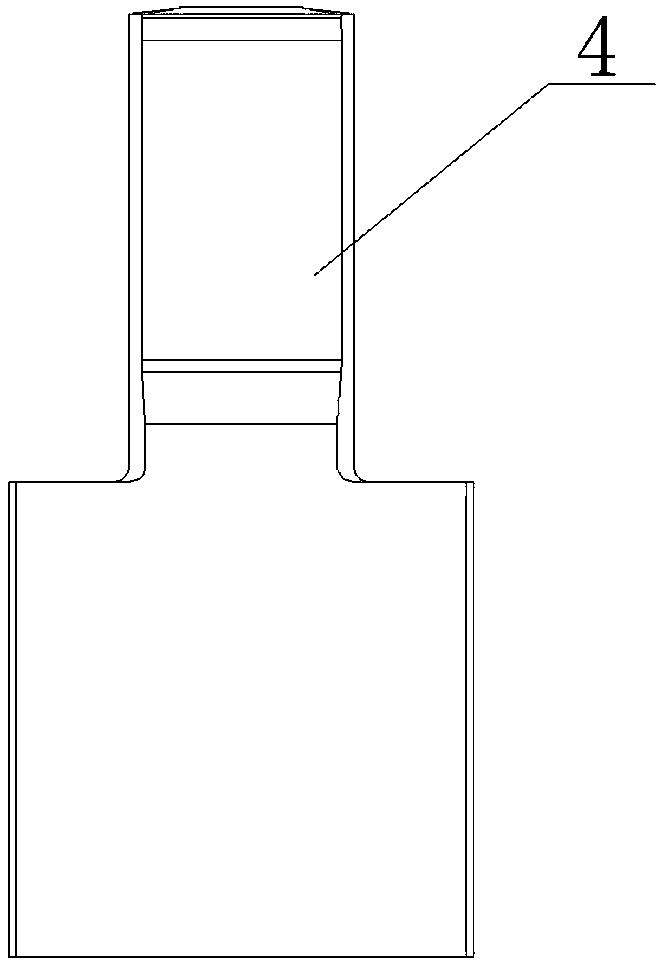

[0017] As shown in the figure, in the rod end open groove cold heading die of the present invention, the rod end open groove A of the shaft part is formed with a counterbore at the rod end before cold heading. The cold heading die includes a mold shell 17, a pad 12, a movable The punching sleeve 6, the pushing rod 2 and the cutting knife 4, the cushion block 12 are fixed on the lower end of the mold shell 17 and are provided with a sleeve 9 extending into the inner hole 15 of the mold shell, and the ejection hole 14 is provided in the middle of the cushion block 12. The ejector rod 13 is movable in the hole 14, and the movable punching sleeve 6 is movable in the inner hole 15 of the mold shell and the upper limit is obtained th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap