Discharging equipment and discharging method of walking beam precision forging process

A walking beam and equipment technology, applied in the field of forging machinery, can solve problems such as occupying workshop space, wasting manpower, and affecting the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

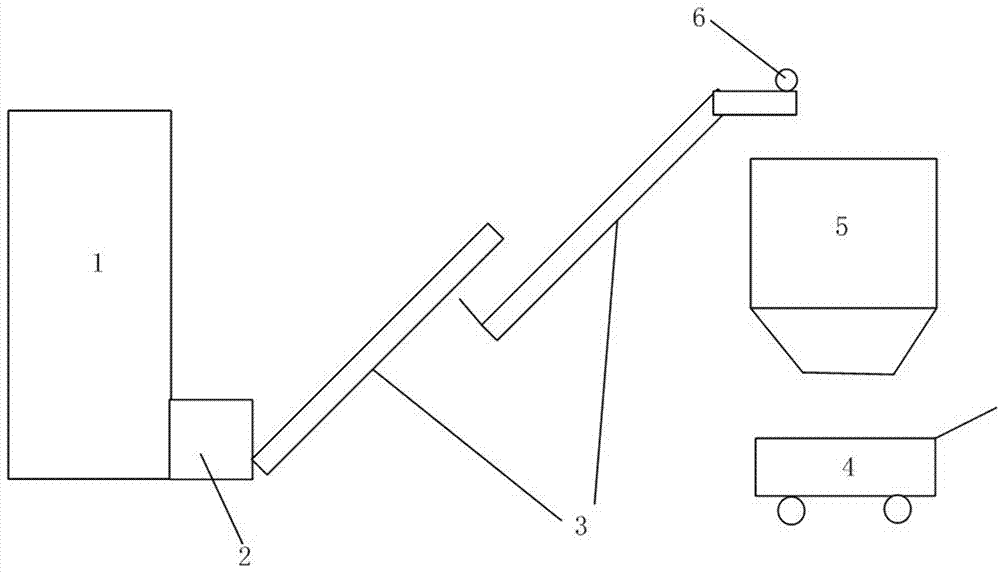

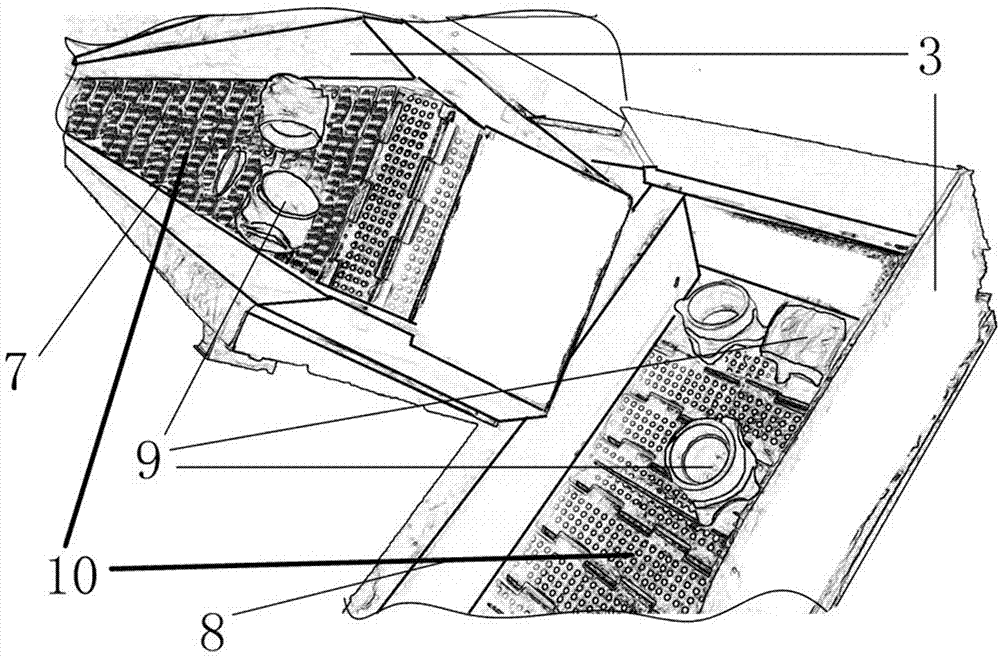

[0029] Such as Figure 1-2 As shown, a discharging device and a discharging method of a walking beam precision forging process are used for discharging small and medium-sized forgings during rapid forging of a walking beam forging device. The discharging device includes a static mechanism and an aggregate mechanism; the static mechanism is connected to the discharge port 2 of the walking beam forging equipment 1; the static mechanism includes a number of plate conveyors 3; the transmission surface 10 of the plate conveyor is formed of heat-resistant metal; each plate The transmission speed of the conveyor 3 is synchronized and matched with the discharge speed of the forging equipment 1; the transmission surface 10 of each plate conveyor forms a resting area for the finished forging 9 with the slow-moving conveying surface; in the conveying direction of the forging in the resting area, the upper The output end of one apron conveyor 7 is adjacent to the input end of the next apr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com