Maintenance time evaluation method based on degree of health

A technology of health and time, applied in the direction of instruments, etc., can solve the problems affecting the service life, affecting the service life of equipment or components, and affecting the service life, and achieve the effect of scientific management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

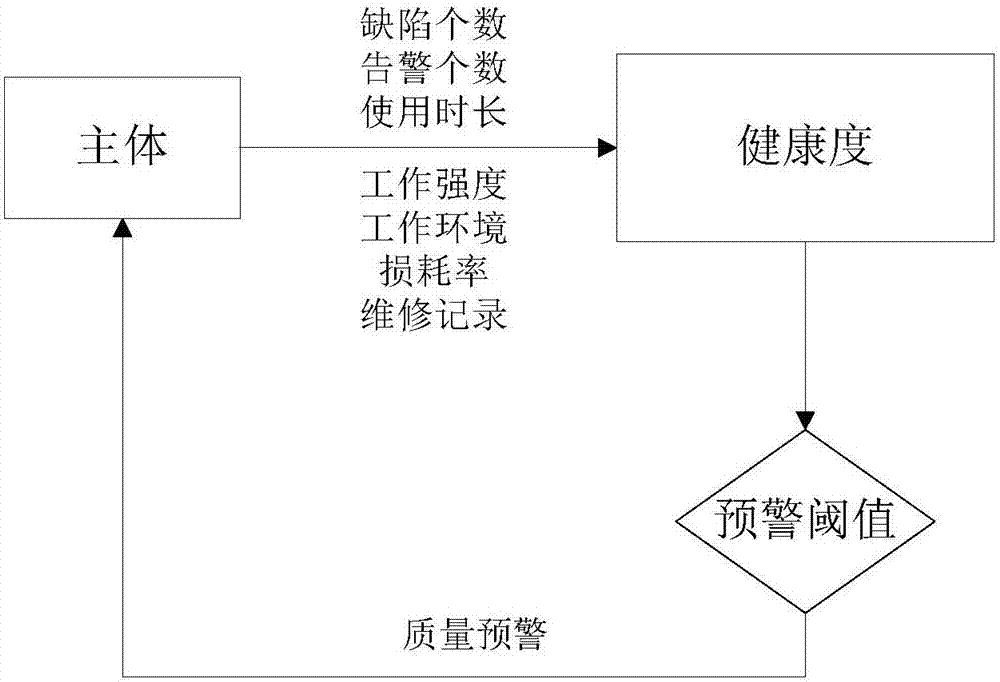

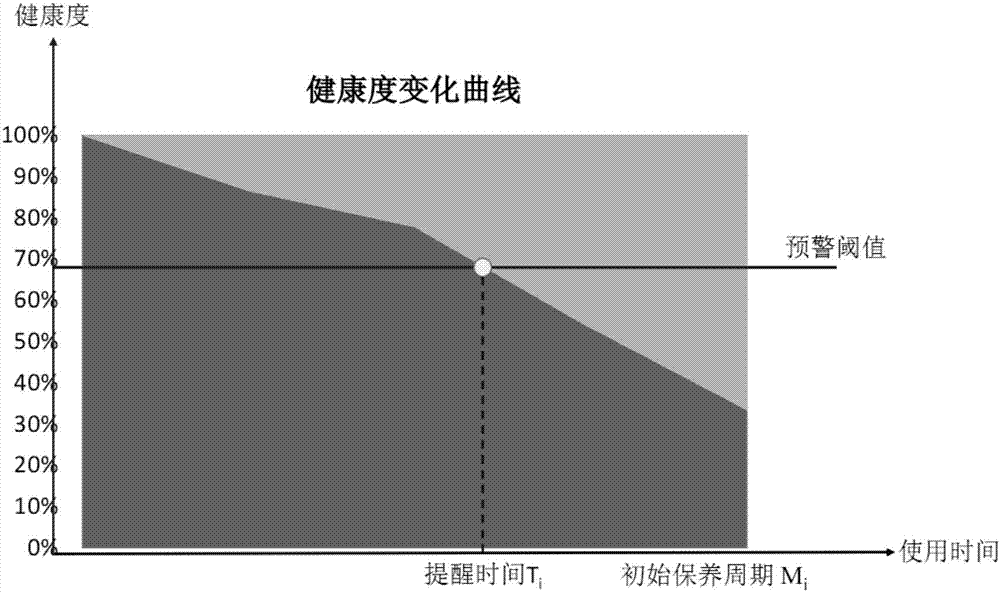

[0048] The present invention is based on the consideration that "the current early warning mechanism for equipment or component configuration generally has the feature of after-the-fact reminder, and this feature may lead to the defect that the service life cycle of equipment or components is affected due to lack of timely maintenance", Through real-time monitoring of the current health of equipment or components, when the current health drops to the corresponding warning threshold, the equipment or components can obtain timely and effective quality warnings. The maintenance time evaluation method of the present invention, on the basis of determining the target maintenance time, reminds the current equipment or parts that should be maintained, that is, on a forward-looking basis, it can more flexibly and intelligently monitor the equipment Or the parts are maintained to eliminate the potential quality hazards of the current equipment or parts in a timely manner, thus realizing ...

Embodiment 2

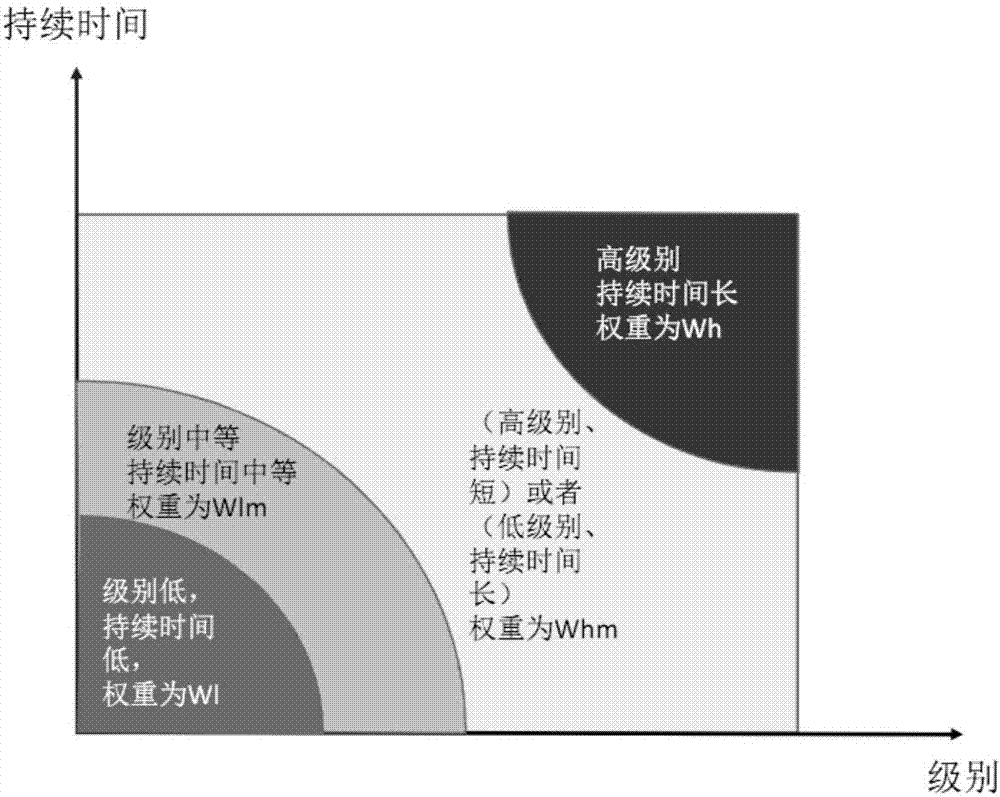

[0060] The present invention is based on the idea that "the initial maintenance cycle is usually a suggested value obtained by the manufacturer of the equipment or parts under the set conditions of use (such as close to the most normal use environment, and at the most normal use intensity). This It is not difficult for people in the field to understand that when the same equipment or component is in different stages of the service life cycle and in different usage scenarios (such as temperature, humidity, etc.), the timing of maintenance should be different.” Considering that, due to the fixed The initial maintenance cycle does not allow the equipment or parts to be maintained in the most timely and appropriate manner. Often, there will be over-maintenance near the delivery date and under-maintenance near the end of the service life cycle. This often deviates from the timing of the health-based quality warning that is more in line with the actual needs of equipment or parts. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com