Welding device

A welding device and electric connector technology, applied in welding protection devices, welding equipment, welding accessories, etc., can solve the problems of loose plug connectors, susceptibility to dust accumulation, accidental electric shock risk, electric welding power supply, etc., to prevent plugging The effect of loosening and improving the stability of the power supply connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

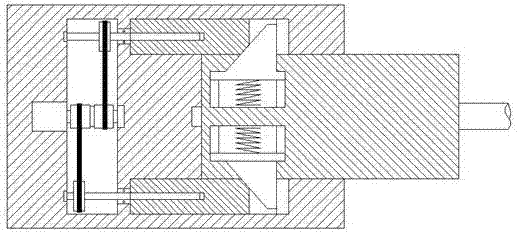

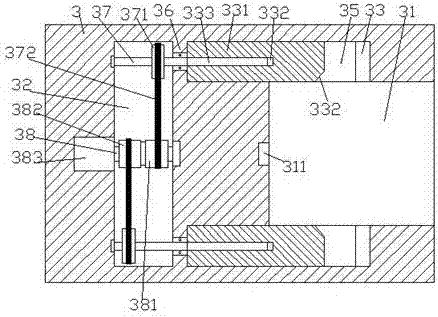

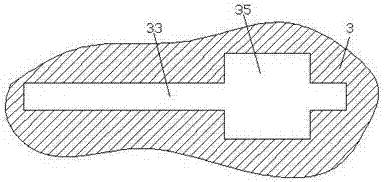

[0021] like Figure 1-Figure 7 As shown, a welding device of the present invention includes a stand 5, a body 6 installed above the stand 5, a lifting block 622, an electric block 3 and an electrical connector 4 arranged in the lifting block 622, the The inner bottom of the frame 5 is provided with a recessed groove 52, and a counterweight 53 is detachably provided in the recessed groove 52, and the bearing capacity of the frame 5 can be increased by the counterweight 53 to prevent the The pedestal 5 is too light to cause the center of gravity to be unstable and topple over. An insertion slot 31 is provided in the right end surface of the energization block, and a locking slot 35 is correspondingly provided in the upper and lower inner walls of the insertion slot 31. The inside of the locking groove 35 is provided with a sliding groove 33 extending to both sides, and the electric block 3 on the left side of the insertion groove 31 is provided with a cavity 32, and the cavity 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com