Mounting equipment of joint bearing dustproof cover

A technology for installing equipment and joint bearings, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of low efficiency, inability to carry out mass production, and backward installation methods, and achieve the effects of large expansion capacity, simple structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

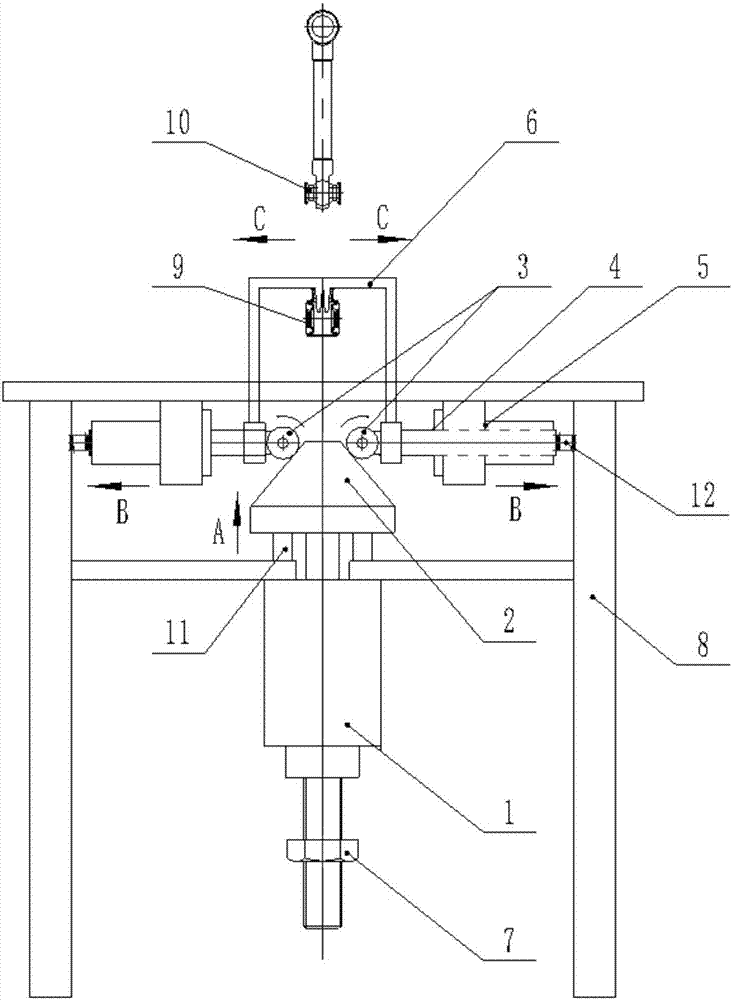

[0012] Such as figure 1 As shown, a joint bearing dust cover installation equipment is characterized in that it includes a cylinder 1, the upper part of the cylinder 1 is provided with a trapezoidal top column 2, and the upper end surface of the top column 2 is in contact with multiple sets of rollers 3 evenly arranged. , each group of rollers 3 is connected to one end of the guide post 4, the other end of each guide post 4 is sleeved in the linear bearing 5, and one end of each linear bearing 5 is connected to the frame body 8; each guide post 4 is respectively connected to the The opening and closing hook 6 is connected.

[0013] Such as figure 1 As shown, a compression spring 12 is provided at one end of the linear bearing 5 of the present invention connected to the frame body 8 .

[0014] Such as figure 1 As shown, a limiting block 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com