Roof snow-melting system of transformer substation

A technology for substations and transformers, applied to roofs, snow traps, roof coverings, etc., can solve problems such as broken rainwater pipes, damage to roof insulation, waterproof structures, and inability to perform snow removal work to achieve energy saving and snow melting operations. The effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

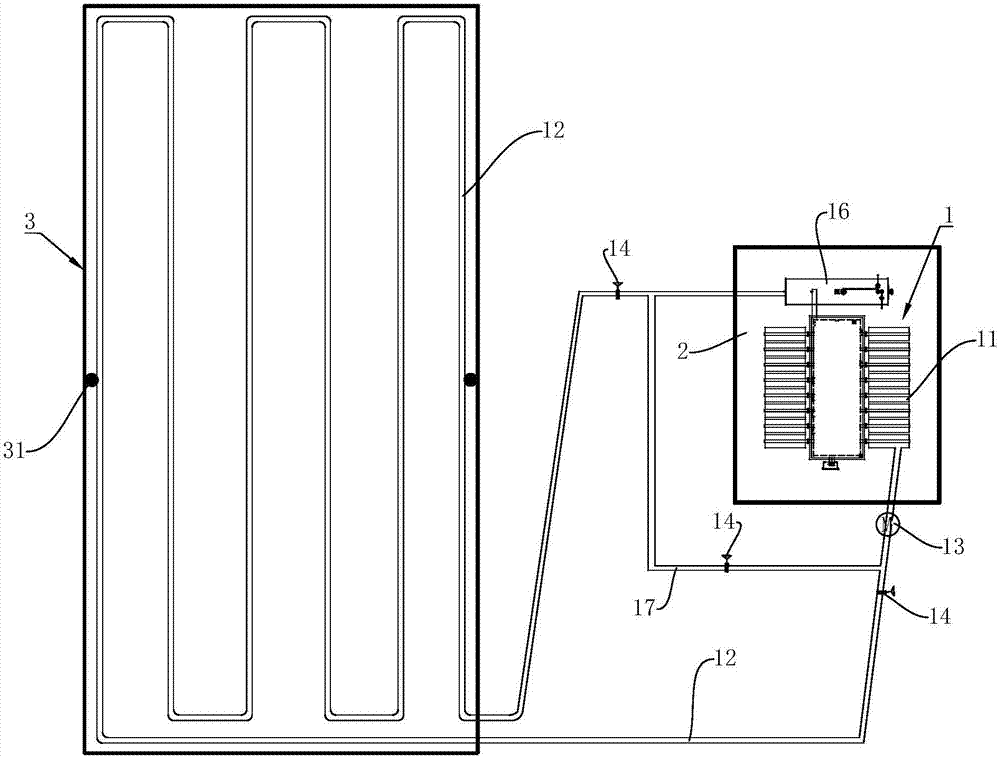

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0013] The roof snow melting system of a substation includes a transformer 1, the transformer 1 is provided with a radiator 11 and an oil conservator 16, the oil conservator 16 stores cooling oil, and the radiator 11 has radiator oil for circulating the cooling oil Road, also includes the snow melting oil pipe 12 and the second oil pipe 17, the oil conservator 16, the cooling oil passage and the snow melting oil pipe 12 are connected in series to form the first circuit, the snow melting oil pipe 12 extends through the roof 3 of the substation building; the second oil pipe 17 The oil conservator 16 and the cooling oil channel are connected in series to form a second circuit, and a pump 13 and a valve 14 are arranged on the first circuit and the second circuit.

[0014] The snow melting system can recycle the heat dissipation of the transformer to melt snow on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com