A processing table device for processing workpieces

A technology for processing workpieces and processing tables, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting work efficiency, raising and lowering adjustment of operators, cumbersome process, etc., and achieves convenient operation and satisfaction Height and azimuth adjustment, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

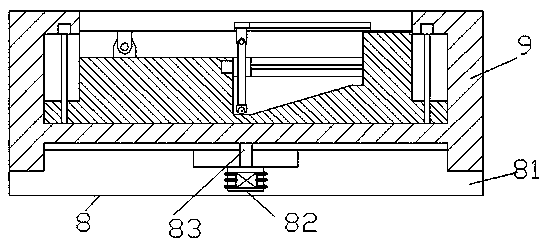

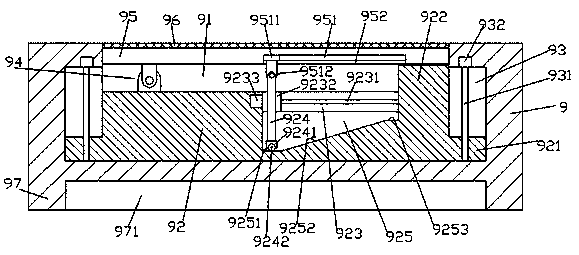

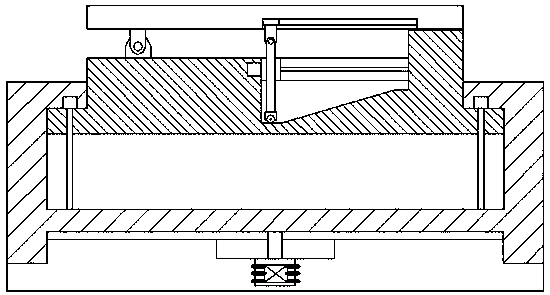

[0022] like Figure 1-Figure 6 As shown, a processing table device for processing workpieces according to the present invention includes a base 8 and a processing table portion 9 arranged on the upper end of the base 8, and a protruding ring 81 is fixed on the outside of the base 8. A third motor 82 is provided at the center of the base 8, and the top end of the third motor 82 is rotatably connected to an upwardly extending rotating shaft 83. The outer casing of the third motor 82 is provided with a heat sink, and the heat sink includes The heat dissipation fins 201 fixedly connected to the outside of the third motor 82 and the heat dissipation fan 202 arranged on the heat dissipation fins 201, the top of the rotating shaft 83 is fixedly connected with the center of the bottom of the processing table part 9, so A protruding block 97 is fixed at the edge of the bottom of the processing table portion 9, and a circular groove 971 is arranged in the protruding block 97, and the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com