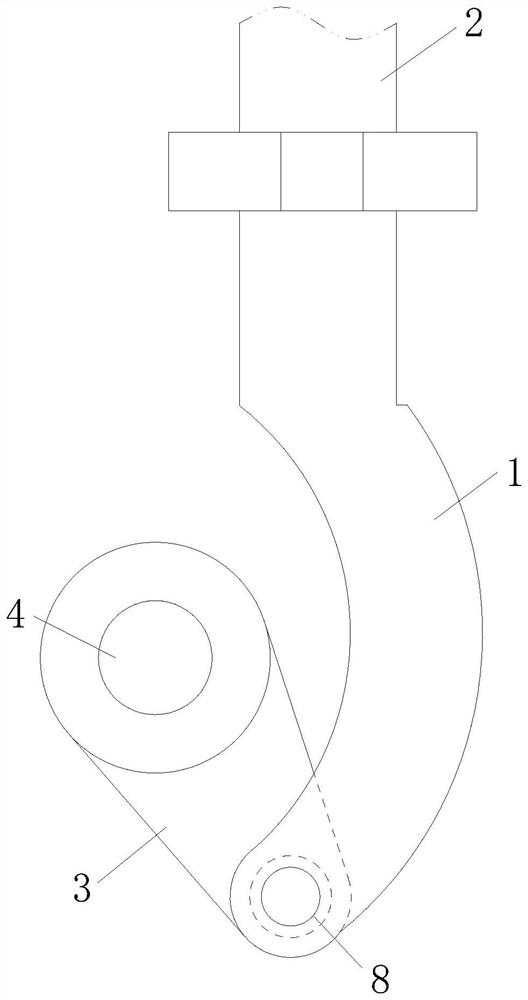

High-voltage circuit breaker connector

A high-voltage circuit breaker and connector technology, used in high-voltage air circuit breakers, contact electrical connections, high-voltage/high-current switches, etc., to achieve the effects of convenient installation, improved working life, and easy disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

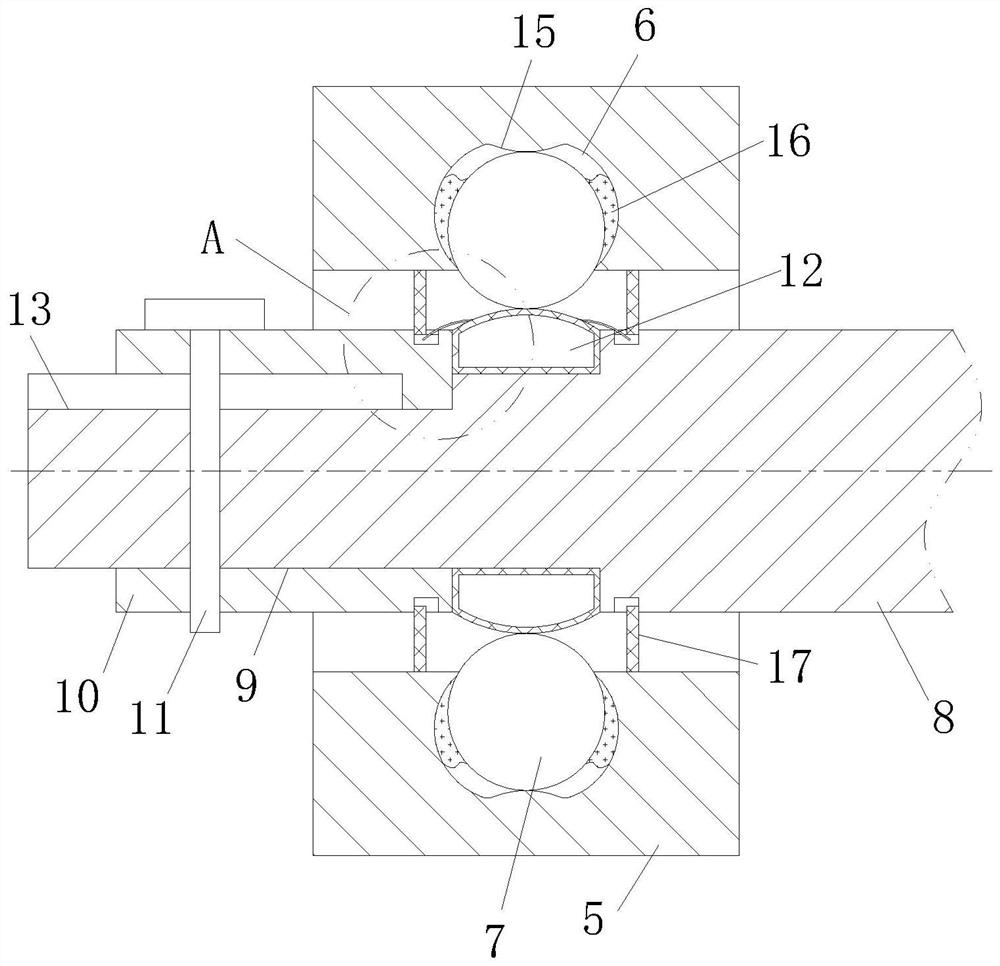

Embodiment 1

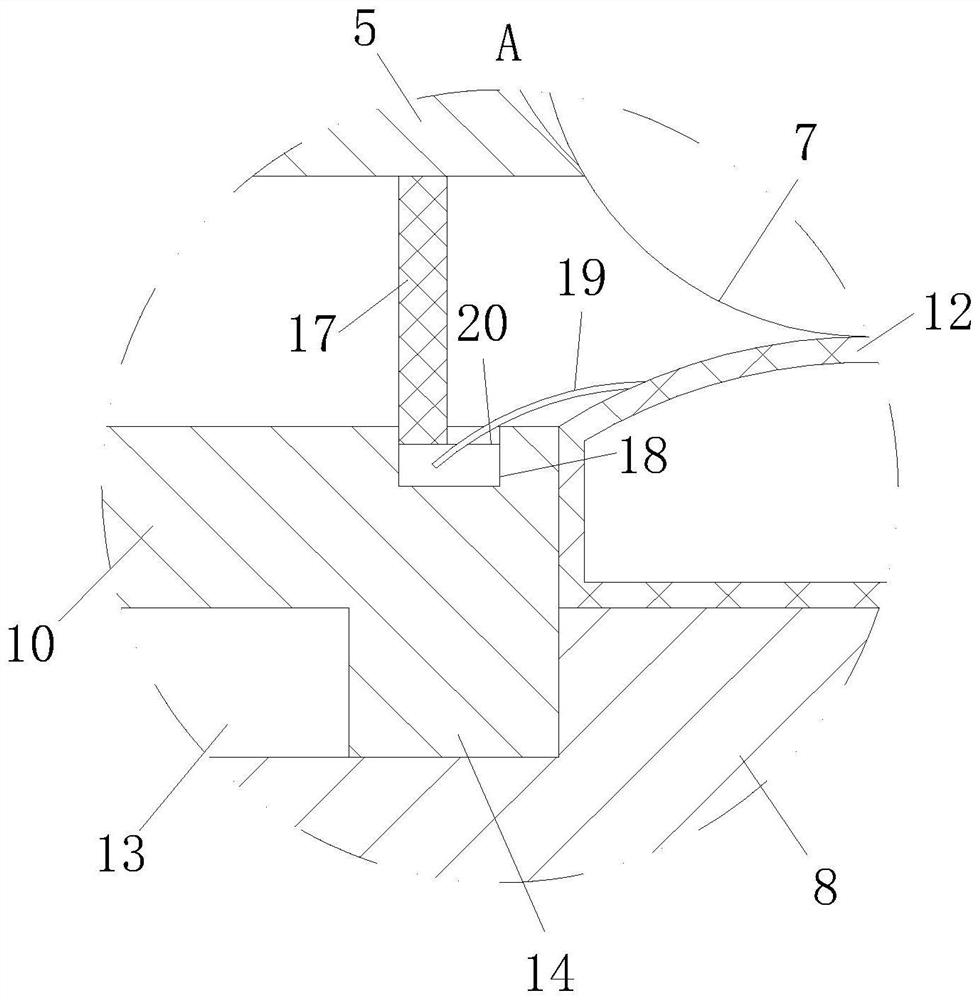

[0030] The inner wall of the swivel 5 corresponding to both sides of the ball 7 is connected with an elastic protective strip 17, and the annular sleeve 10 is respectively provided with an annular groove 18 at the corresponding sidewall position of the rotating rod 8 and the protective strip 17, so that The free end of the protective strip 17 extends into the interior of the annular groove 18 and is attached to the side wall; the protective strip 17 and the annular groove 18 can shield and protect the rollers and the elastic ring 12 exposed to the external environment. Protection, reducing water vapor or dust impurities falling to the ball 7 or the elastic ring 12, which will affect the life of the ball 7 and the elastic ring 12.

[0031] The side of the top of the elastic ring 12 close to the protective strip 17 is connected with a shaking strip 19, and the other end of the shaking strip 19 extends into the inside of the annular groove 18, and the corresponding annular grooves...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com