Station adjusting equipment for butchery

A technology for adjusting equipment and slaughterhouses, applied to slaughterhouse equipment, slaughtering, slaughtering equipment, etc., can solve the problems of low processing efficiency, time-consuming and laborious, etc., achieve stable operation, convenient station adjustment, and avoid interference and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

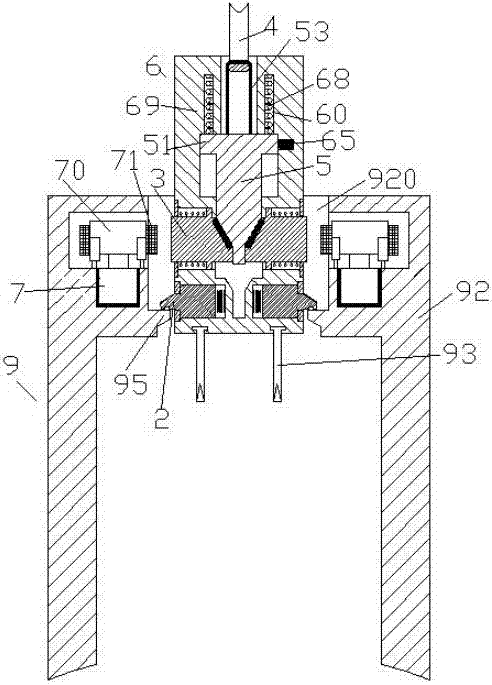

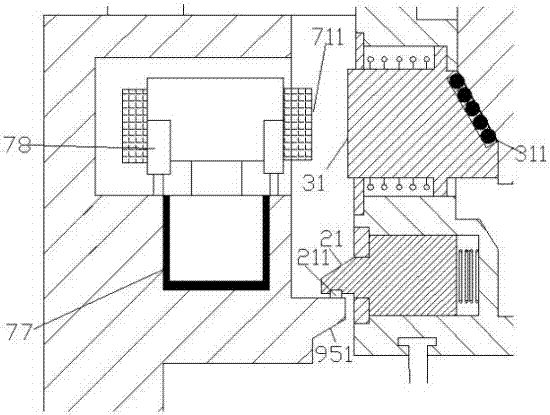

[0008] Combine below Figure 1-2 The present invention will be described in detail.

[0009] According to the embodiment of the present invention, the position adjustment equipment of a slaughterhouse is used to adjust the position of post-mortem livestock, including a support frame body 9, a crossbeam body 92 fixedly installed on the support frame body 9 and extending forward and backward, and a To be connected with the support frame body 9 of the beam body 92 and the suspension adjustment assembly 6 fixedly connected with the workpiece 93 and capable of moving in the middle channel 920 of the beam body 92, wherein the suspension adjustment The assembly 6 includes a main body 69, elastically telescopic and sliding support feet 2 and joints 3 for front and rear driving symmetrically arranged on both sides of the main body 69, wherein a telescopic joint is arranged between the two joints 3 for front and rear drive. Operate the lifting member 5, the top of the telescopic operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com