Realization method based on the bending of steel bars with different diameters

A realization method and steel bar technology, applied in the field of steel bar processing equipment, can solve problems such as inability to bend steel bars of different diameters and affect the bending efficiency of steel bars, and achieve the effect of improving work efficiency and easy bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

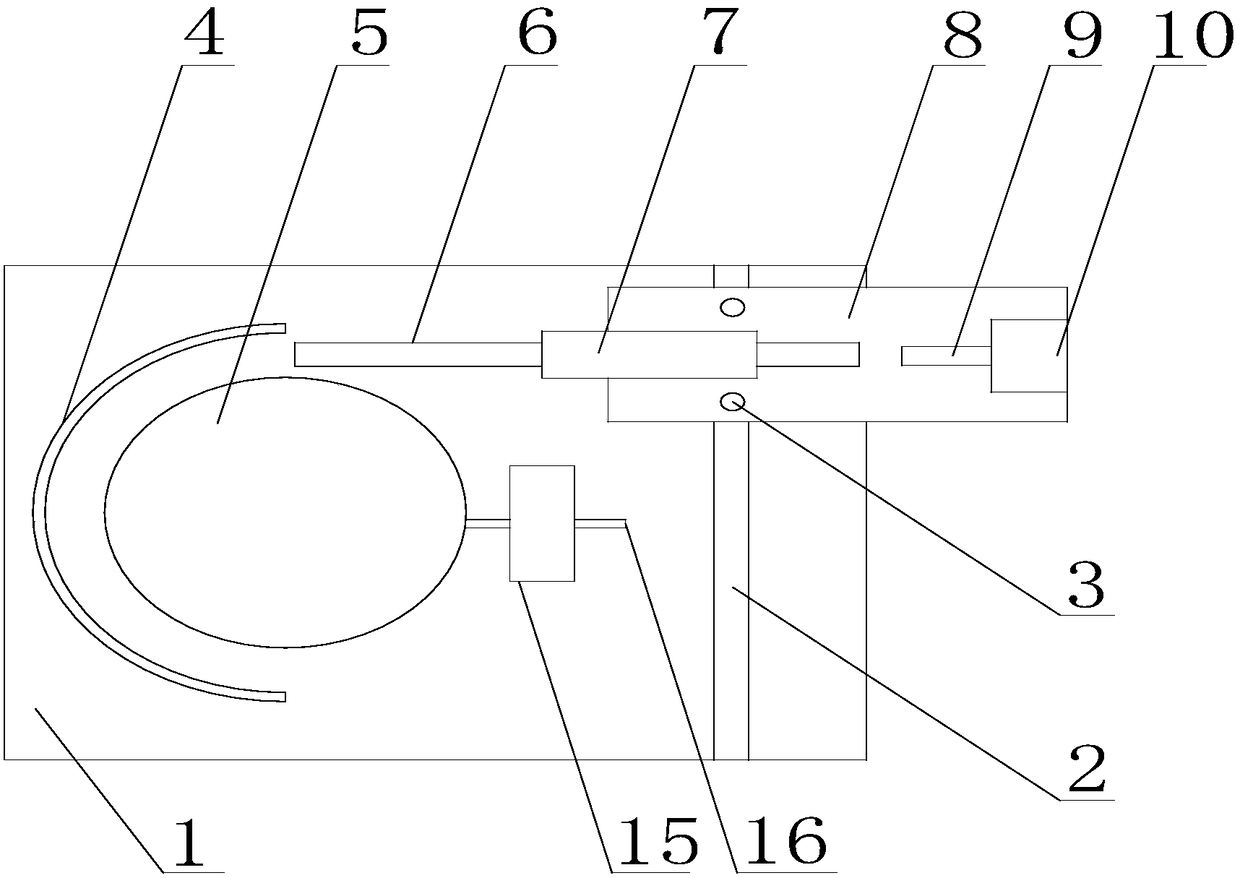

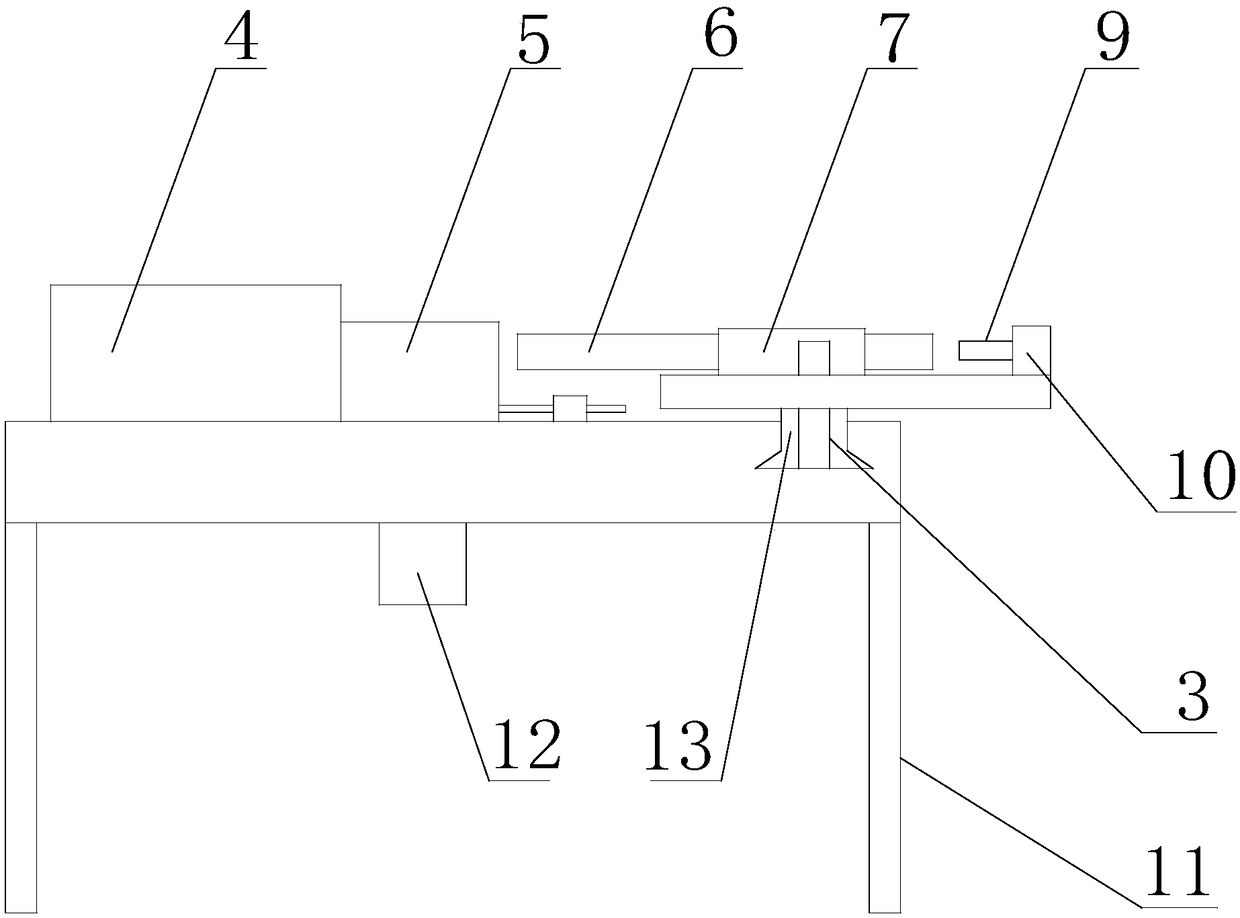

[0026] Such as Figure 1 to Figure 4 As shown, the present invention is based on the method of bending steel bars of different diameters, including the following steps: first, the rotating table 5 is moved according to the diameter of the steel bar 6 to be bent, so that the arc formed between the rotating table 5 and the boss 4 The shaped track can pass through the steel bar 6, and the movable rod 16 is rotated so that the movable rod 16 is in contact with the side wall of the turntable 5, and then the steel bar 6 to be bent is placed in the second through hole 72 of the guide cylinder 7, and the support table 8 moves in the groove 2, so that the steel bar 6 is aligned with the arc-shaped track opening formed by the rotating platform 5 and the boss 4, and the positioning rod 3 is adjusted so that the positioning rod 3 is pressed in the groove 2, and the supporting platform 8 is fixed on the On the groove 2, then energize the heating wire 71 in the guide cylinder 7. After the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com