Suitable for steel bending devices of different diameters

A technology of bending device and steel bar, applied in the field of steel bar bending device, can solve problems such as affecting the bending efficiency of steel bar, unable to bend steel bars of different diameters, etc., to achieve the effect of easy bending and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

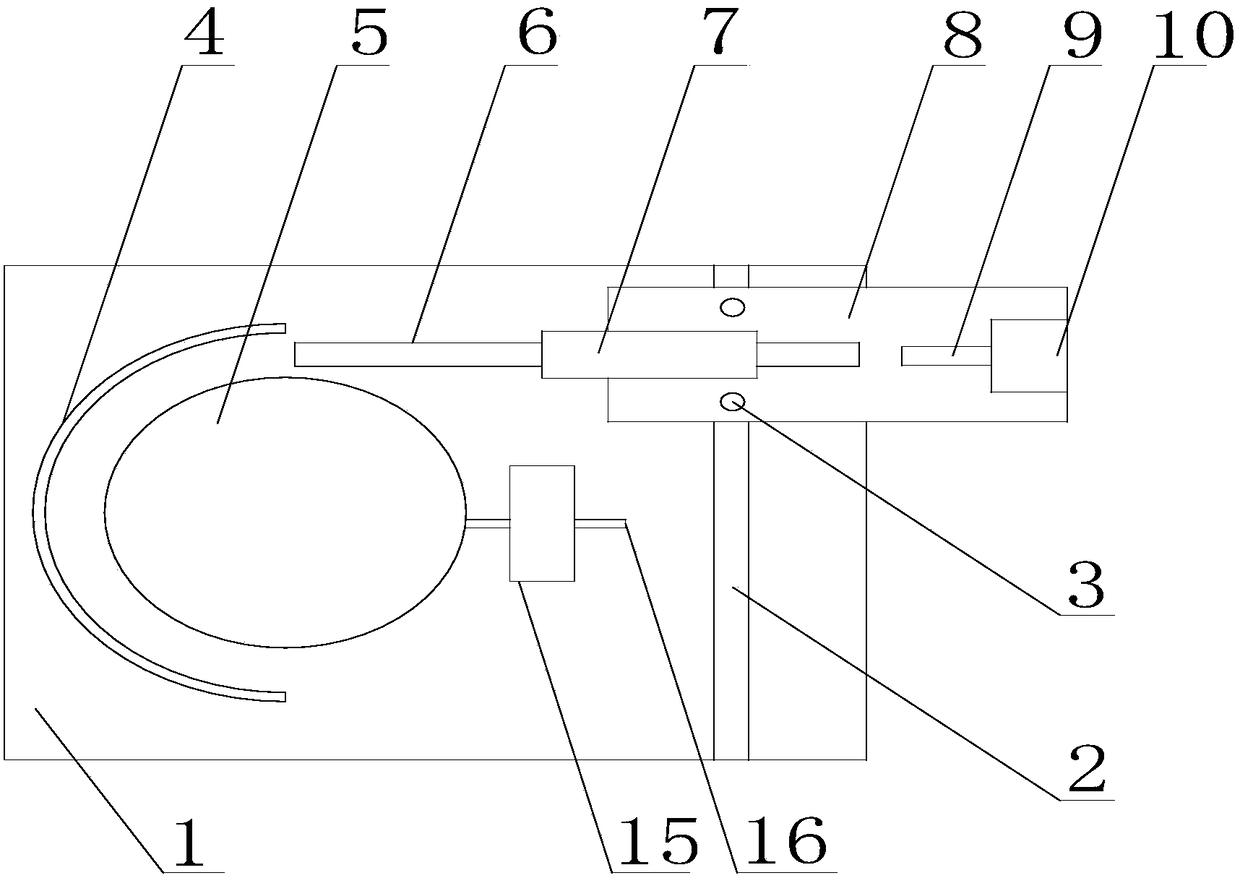

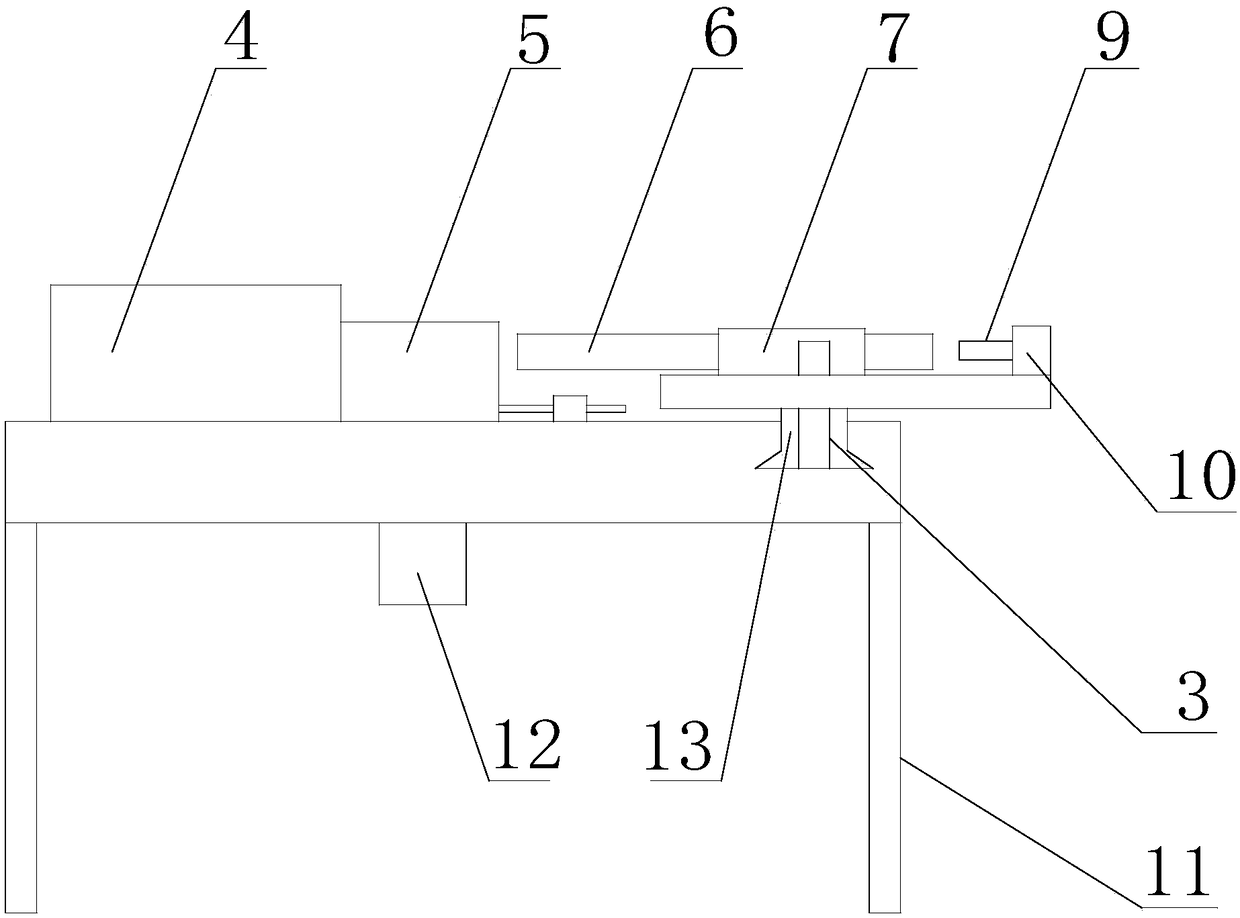

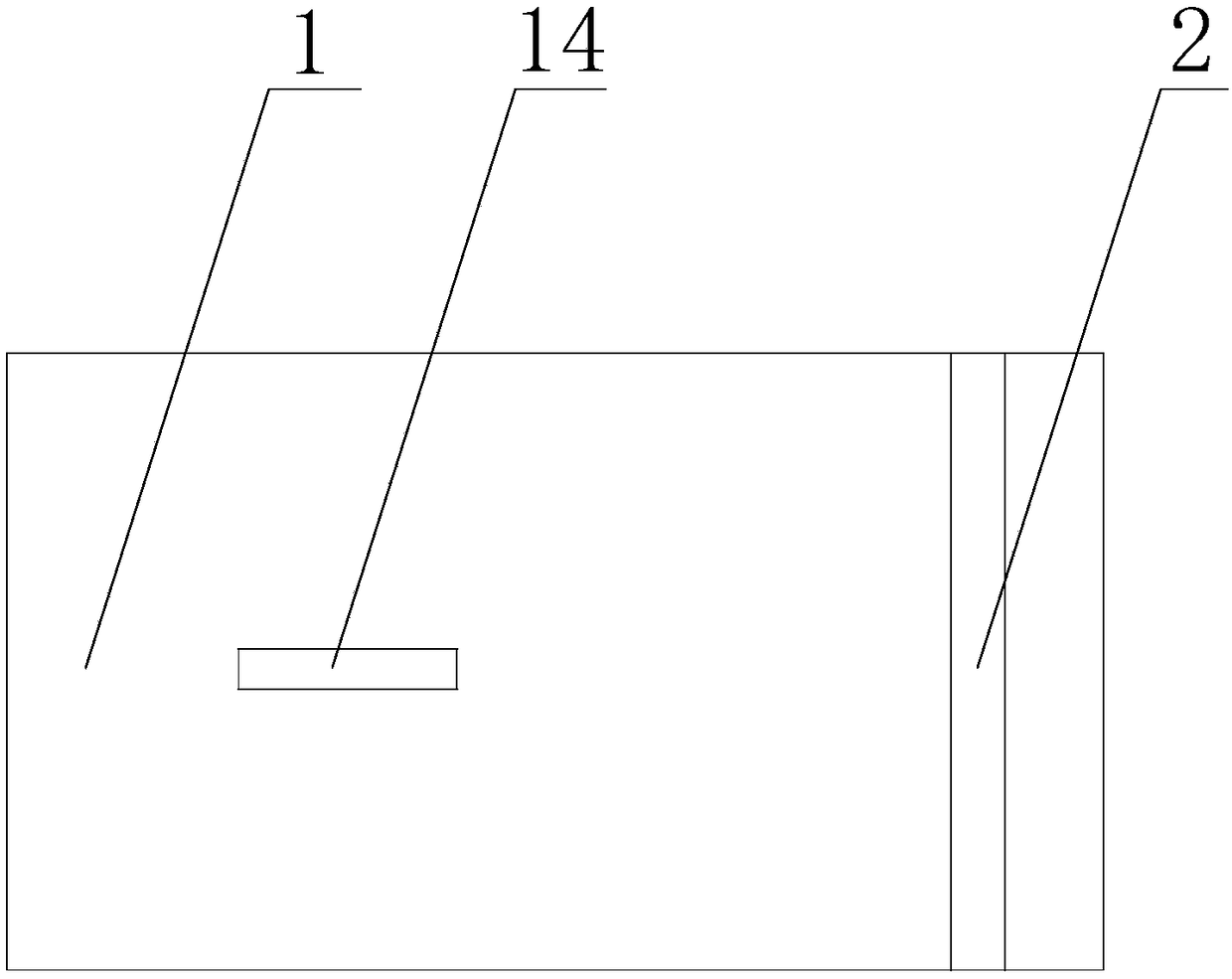

[0024] Such as Figure 1 to Figure 4 As shown, the present invention is applicable to steel bar bending devices of different diameters, including a workbench 1 and support feet 11, the support feet 11 are installed at the four corners of the bottom of the workbench 1, and the top of the workbench 1 is provided with a boss 4, the boss 4 is an arc shape, and the boss 4 is made of cast iron. The top of the worktable 1 is also provided with a first through hole 14, the first through hole 14 is rectangular, and the first through hole 14 is located on the boss 4. In the arc-shaped area of the first through hole 14, a rotating shaft is provided, and the rotating shaft can move along the horizontal direction in the first through hole 14 to change the distance between the rotating shaft and the boss 4. The bottom end of the rotating shaft is provided with a second Two driving mechanisms 12, the second driving mechanism 12 is preferably a motor, which is easy to buy on the market and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com