Polyester resin for toner, method for producing polyester resin for toner, and toner

一种聚酯树脂、制造方法的技术,应用在显影剂、仪器、电记录术等方向,能够解决安全担忧、耐粘连性、带电特性等调色剂特性损害、调色剂特性不良影响等问题,达到低温固定性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

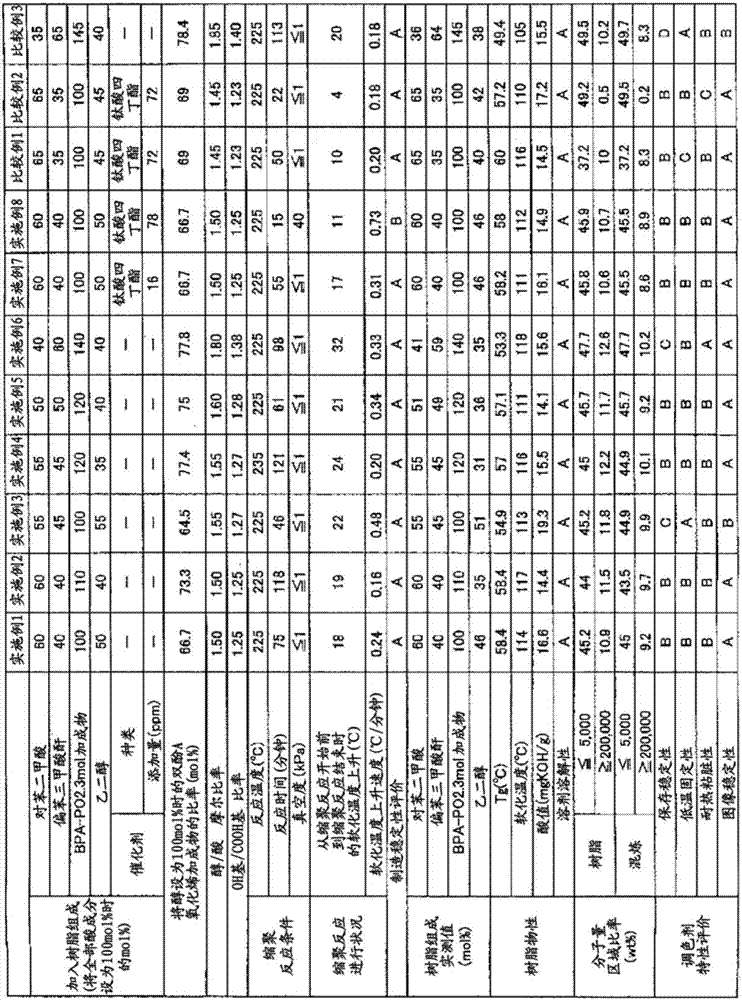

[0148] The polyhydric carboxylic acid and polyhydric alcohol of the addition composition shown in Table 1 were put into the reaction container equipped with the distillation column. Next, the rotation speed of the stirring blade in the reaction container was kept at 200 rpm, the temperature was raised, and the temperature in the reaction system was heated to 265° C., and the temperature was maintained. The esterification reaction was carried out until water no longer distilled from the reaction system.

[0149] Next, reduce the temperature in the reaction system to adjust to the polycondensation reaction temperature shown in Table 1. After collecting a small amount of the contents, reduce the vacuum in the reaction vessel to below 1 kPa for about 20 minutes, while allowing the diol component to escape from the reaction system. Distillation while carrying out polycondensation reaction. Continue the reaction directly while maintaining a high vacuum state, the viscosity of the r...

Embodiment 2)~( Embodiment 6

[0152] (Example 2) to (Example 6), (Comparative Example 4)

[0153] The polycarboxylic acid and polyhydric alcohol added to the reaction container were changed as shown in Table 1, except that, the polyester resin was obtained by the same method as in Example 1, and the toner was prepared by the same method as in Example 1. change. Table 1 shows the characteristic values of the obtained resin and the evaluation results of the toner.

Embodiment 7

[0155] The polyvalent carboxylic acid and polyhydric alcohol charged into the reaction container were changed as shown in Table 1, and the polymerization catalyst shown in Table 1 was added together with the raw materials, and polyester was obtained by the same method as in Example 1. The resin was converted into a toner by the same method as in Example 1. Table 1 shows the characteristic values of the obtained resin and the evaluation results of the toner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com