Multi-executing-mechanism compressor valve block punching machining device

A multi-actuating mechanism and processing device technology, applied in the field of mechanical processing, can solve problems such as troublesome operation, time-consuming and labor-intensive operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

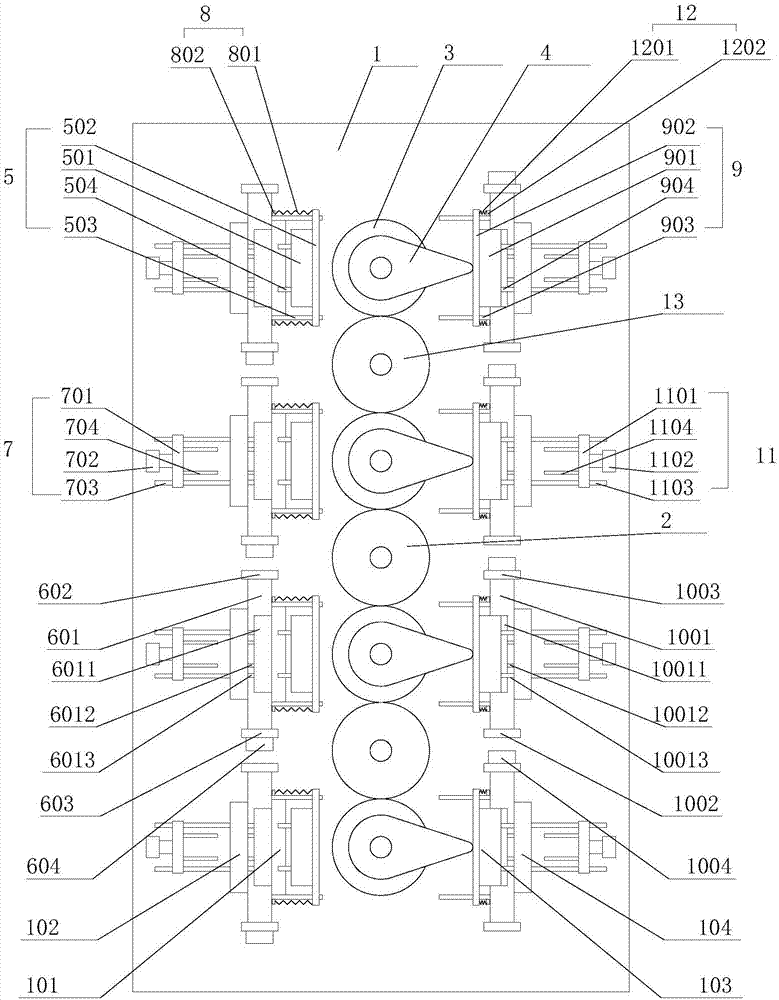

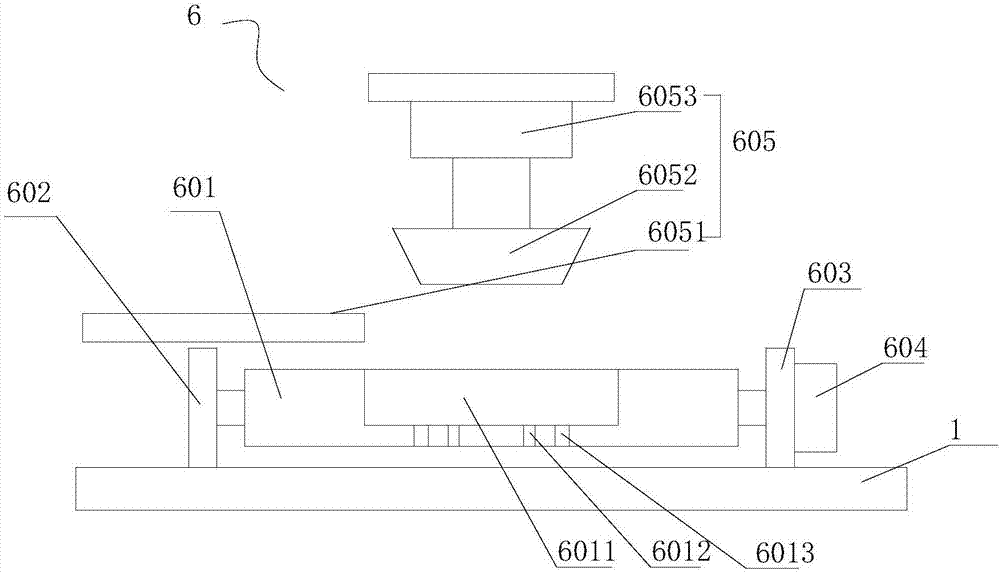

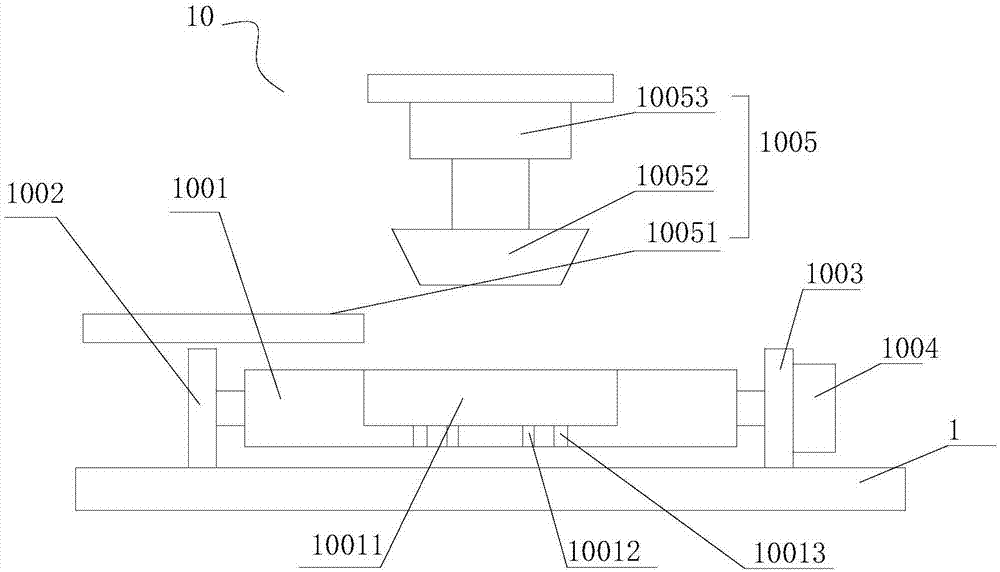

[0022] refer to Figure 1-Figure 3 , the present invention proposes a multi-executing mechanism compressor valve plate punching processing device, including a workbench 1, a power mechanism, a first punching actuator and a second punching actuator, wherein:

[0023]The power mechanism comprises a driving gear 2, a plurality of driven gears 3, a plurality of cams 4 and a first driving mechanism, the driving gear 2 and a plurality of driven gears 3 are all installed on the workbench 1, and the driving gear 2, a plurality of driven gears The gear 3 is linearly distributed along the length direction of the workbench 1 and a plurality of driven gears 3 are distributed on both sides of the driving gear 2. A transmission gear 13 is arranged between any adjacent two driven gears 3 and the two driven gears Driven gear 3 all meshes with this transmission gear 13, and two driven gears 3 closest to drive gear 2 all mesh with drive gear 2; The quantity of cam 4 is consistent with the quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com