Automatic blanking and punching forming machining device

A blanking punching and forming processing technology, applied in the field of mechanical processing, can solve the problems of time-consuming, laborious and troublesome operation, and achieve the effect of improving work efficiency and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

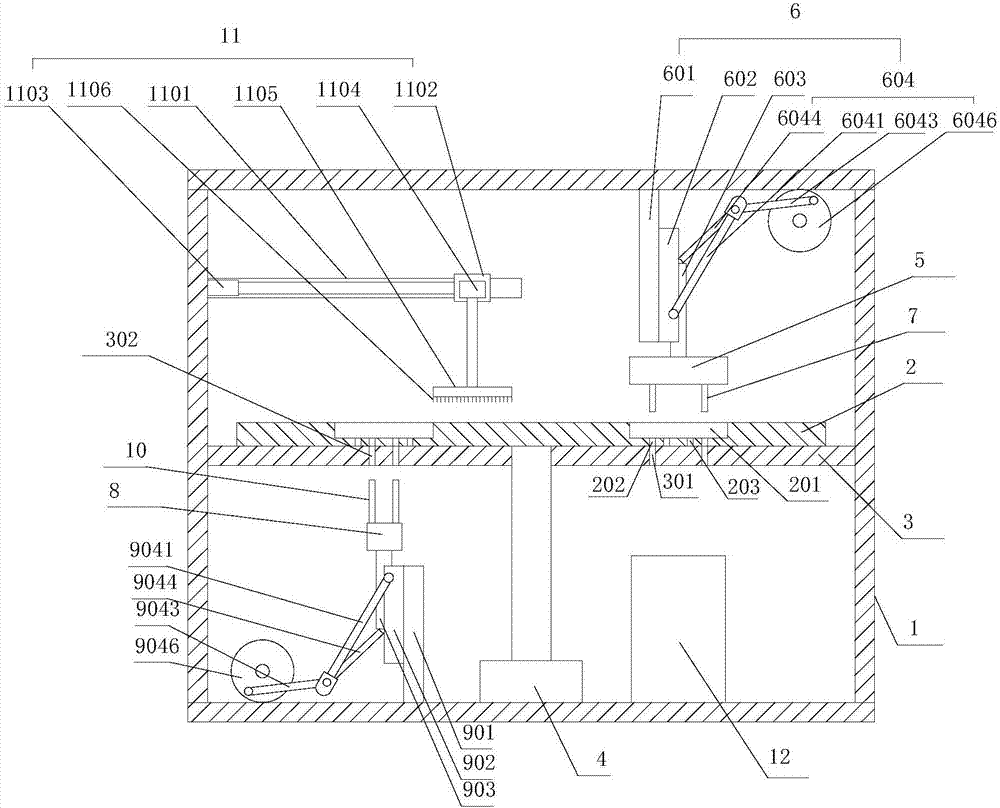

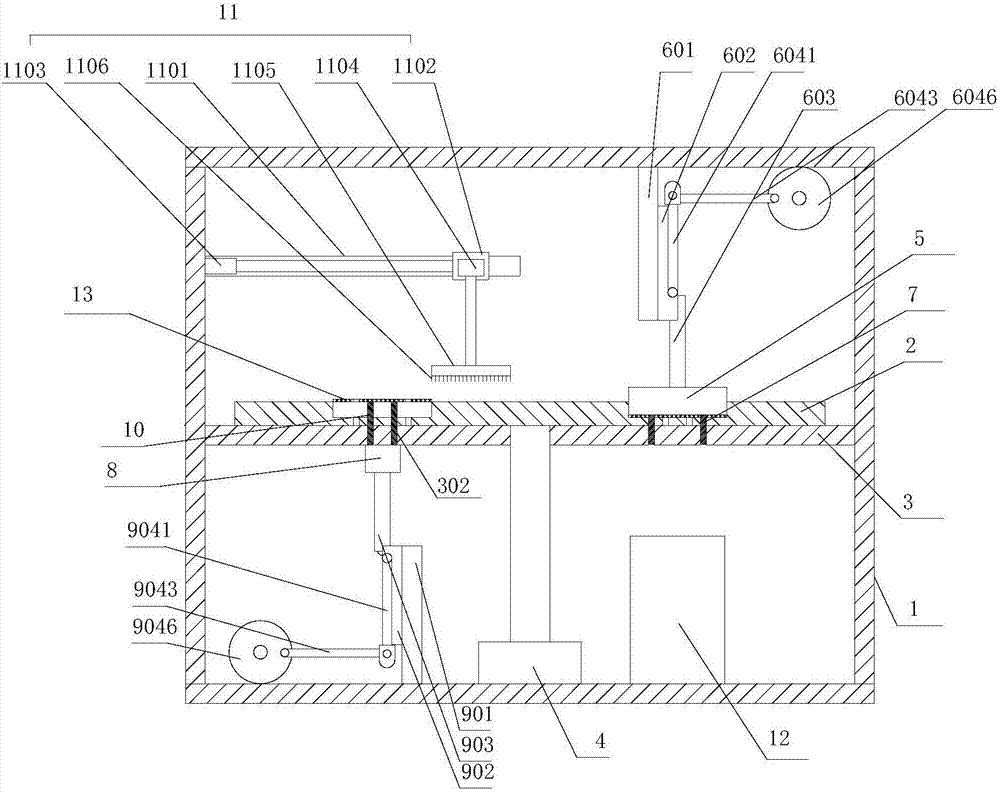

[0025] refer to figure 1 , figure 2 , the present invention proposes an automatic blanking punching forming processing equipment, comprising a frame 1, a workbench 2, a support platform 3, a driving mechanism 4, a punching mechanism, a material ejecting mechanism and a material sweeping mechanism 11, wherein:

[0026] The workbench 2 is arranged horizontally. The upper end of the workbench 2 is provided with N forming grooves 201, where N is a natural number and N≥1. The bottom of the forming groove 201 is provided with a plurality of first blanking holes 202 and A plurality of first ejector holes 203 run through its upper and lower surfaces.

[0027] The driving mechanism 4 is installed on the frame 1, and the driving mechanism 4 is connected with the workbench 2 so that the workbench 2 rotates.

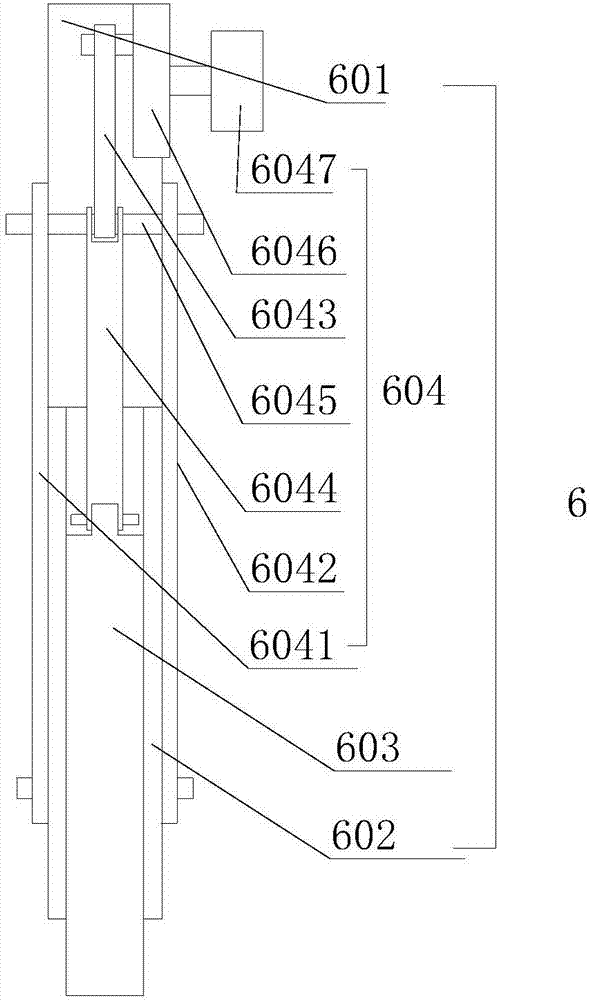

[0028] The punching mechanism is located above the workbench 2 for punching the workpiece in the forming groove 201 , and the punching mechanism includes a punching die 5 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com