Continuous piercing equipment for valve block of compressor

A processing equipment and compressor technology, applied in the field of mechanical processing, can solve problems such as troublesome operation, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

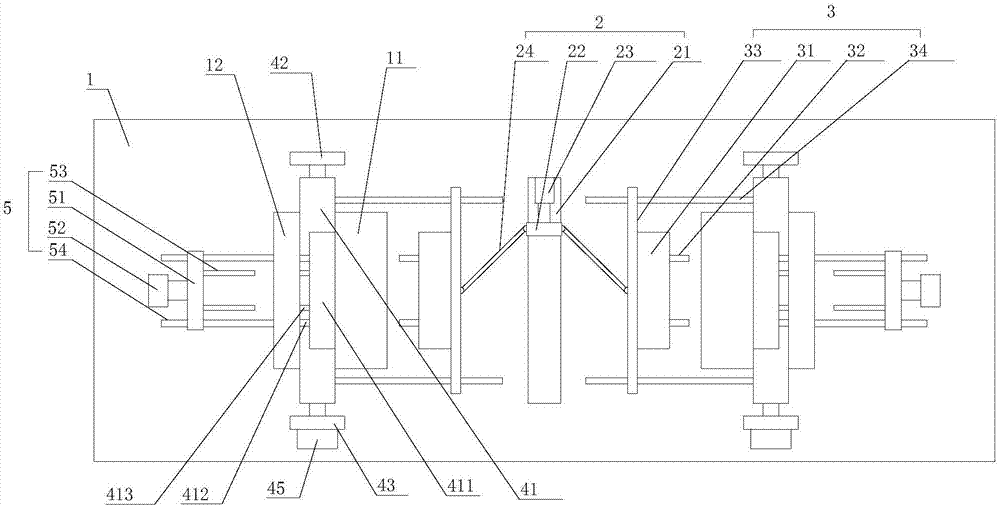

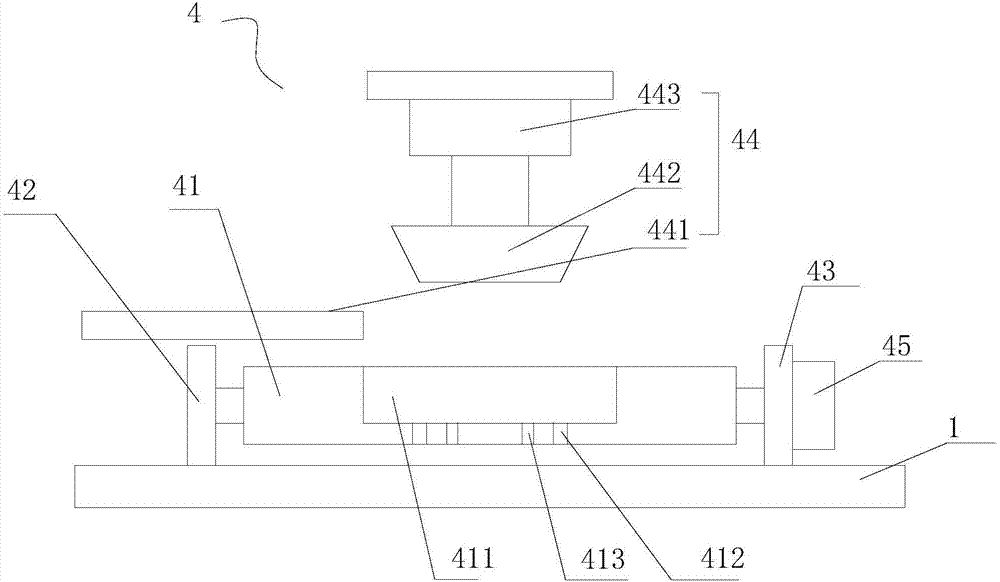

[0021] refer to figure 1 , figure 2 , the present invention proposes a continuous punching processing equipment for compressor valve plates, including a workbench 1, a first driving mechanism 2, two punching mechanisms 3, two fixing mechanisms 4 and two unloading mechanisms 5, wherein:

[0022] The first driving mechanism 2 is installed on the workbench 1 .

[0023] Two punching mechanisms 3 are respectively arranged on both sides of the first drive mechanism 2 and the connection direction of the two punching mechanisms 3 is consistent with the length direction of the workbench 1. The punching mechanism 3 includes a punching die 31 and a moving plate 33 And two first guide rails 34 installed on the workbench 1, the punching die 31 is provided with a punching head 32 away from the first driving mechanism 2 side, the extension direction of the first guide rail 34 is consistent with the length direction of the workbench 1, Both ends of the bottom of the moving plate 33 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com