Convenient and rapid side-surface-screw-screwing-in structure

A screw, a convenient technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems such as difficult to control the screwing speed of the lateral screw hole, difficult operation of the operator, and reduced work efficiency, so as to achieve convenience and high efficiency Manipulation, avoiding space constraints, avoiding difficult-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

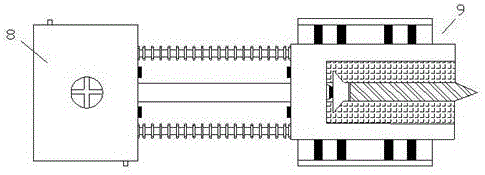

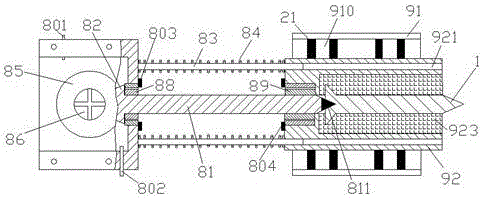

[0011] Combine below Figure 1-4 The present invention will be described in detail.

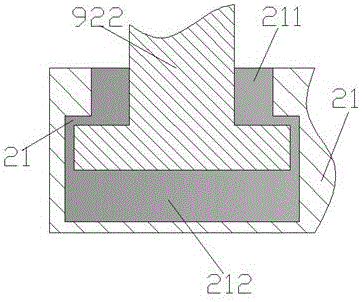

[0012] According to an embodiment of the present invention, a convenient structure for screwing in screws from the side is used for screwing in screws from the side relative to the direction the operator is facing, including installing a positioning component (9) and screwing in a driving component (8 ), wherein the installation and positioning assembly includes a fixed positioning chassis (91) and a screw receiving plate (92), and the bottom of the screw receiving plate (92) is provided with sliding feet (922) for connecting with the fixed The elastic friction lining (21) in the chute (910) of the positioning chassis (91) engages, and the elastic friction lining (21) includes two sides of the sliding foot (922) to align the sliding foot The elastic clamping part (211) clamped and positioned by the part (922) and the elastic telescopic part (212) located on the bottom side of the sliding foo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com