Detection device and adjusting method for objective lens roof of photo-etching machine

A detection device and a technology for engraving objects, which are applied in the field of lithography machines, can solve problems such as compact space layout, low precision indicators, and affecting installation accuracy, and achieve the effects of avoiding space constraints, long detection strokes, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

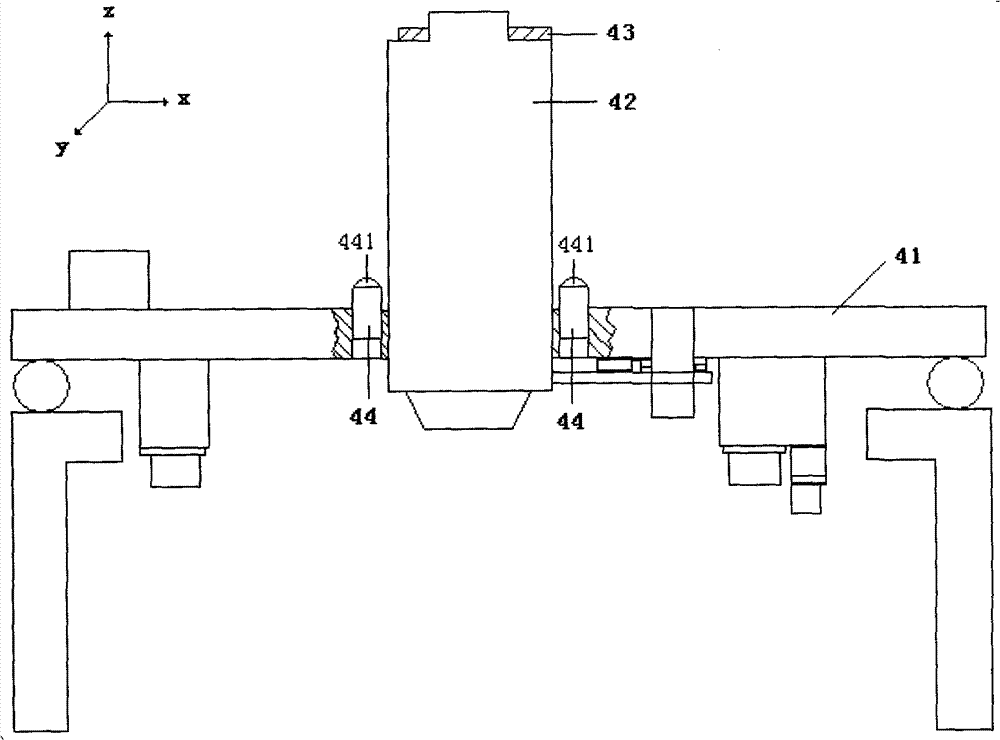

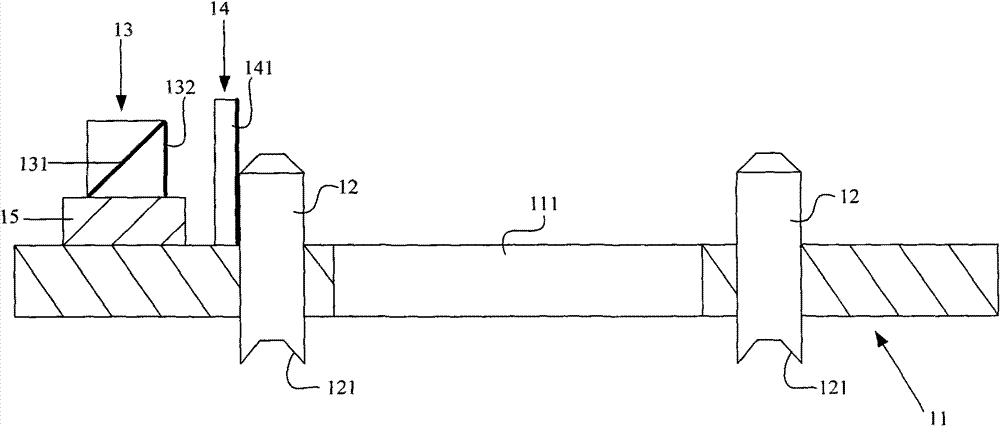

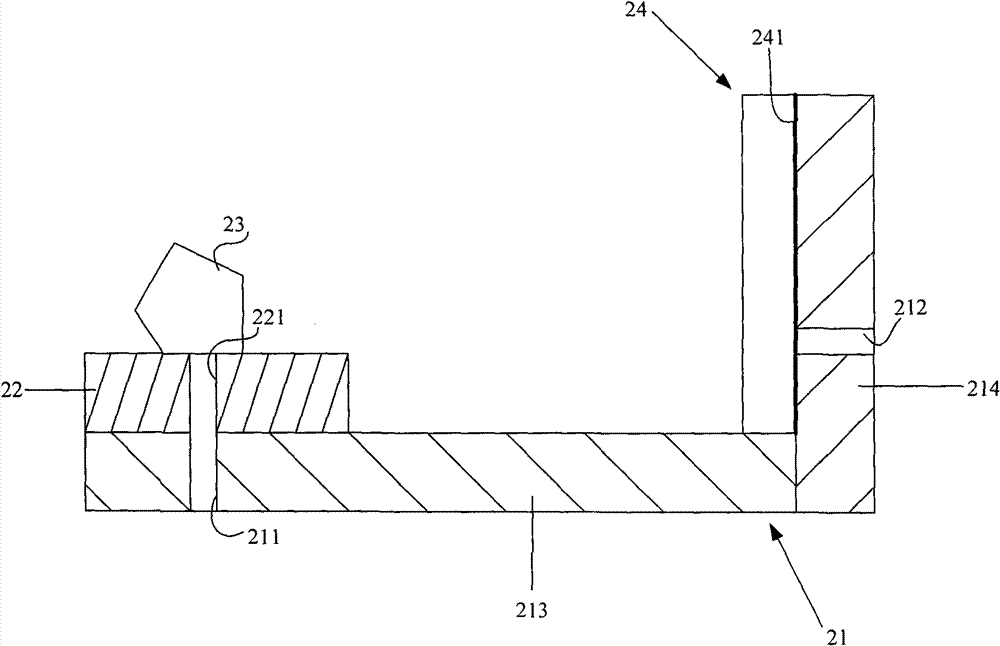

[0035] The following will combine Figure 2 to Figure 9 The detection device and adjustment method of the objective lens top plate of the lithography machine of the present invention will be further described in detail.

[0036] The detection device of the objective lens top plate of the lithography machine of the present invention comprises a lower plate assembly, an upper plate assembly, an autocollimation telescope and an objective lens top plate reference mirror;

[0037] The outgoing beam of the self-collimating telescope is incident on the lower plate assembly, a part of the beam incident on the lower plate assembly is directly reflected back to the self-collimating telescope by the lower plate assembly, and the rest is passed through the After being reflected by the lower plate assembly, it enters the upper plate assembly, and the light beam injected into the upper plate assembly is reflected by the upper plate assembly multiple times and then hits the objective top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com