A linear motor module with side opening structure

A technology of linear motors and side openings, which is applied in the direction of electric components, structural connections, magnetic circuit shape/style/structure, etc., and can solve problems such as slow glue filling speed, increased stator shell diameter, and fast coil heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

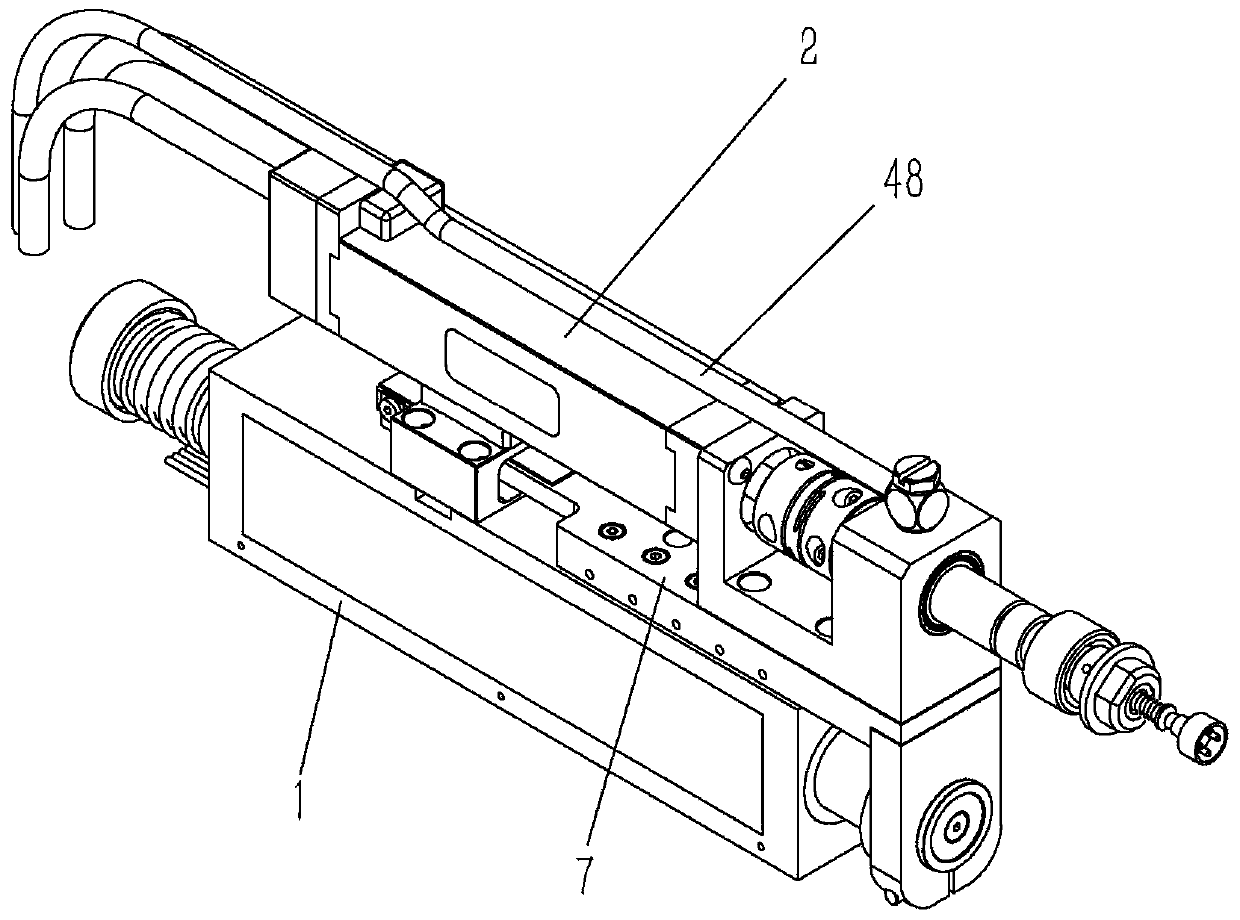

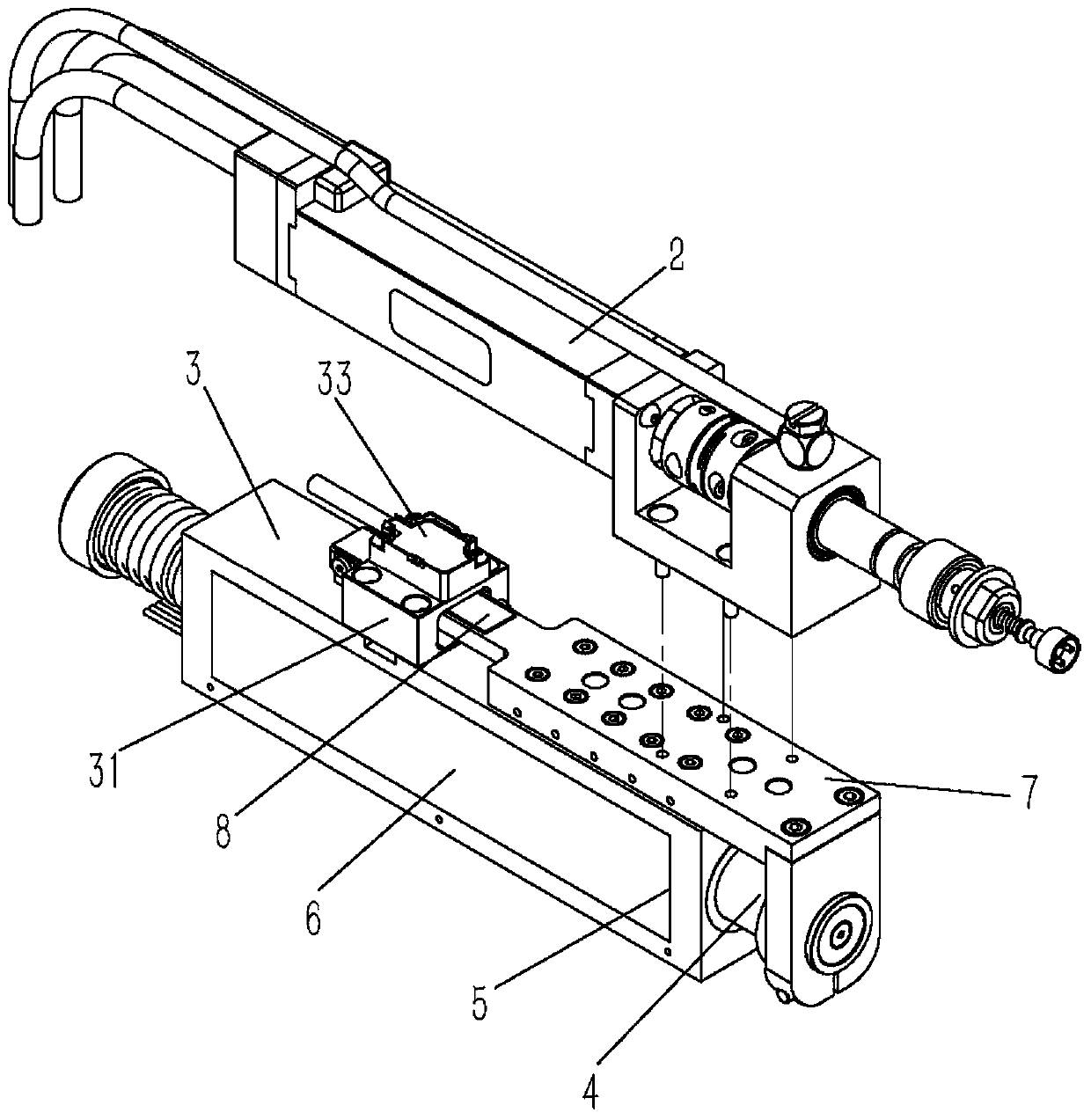

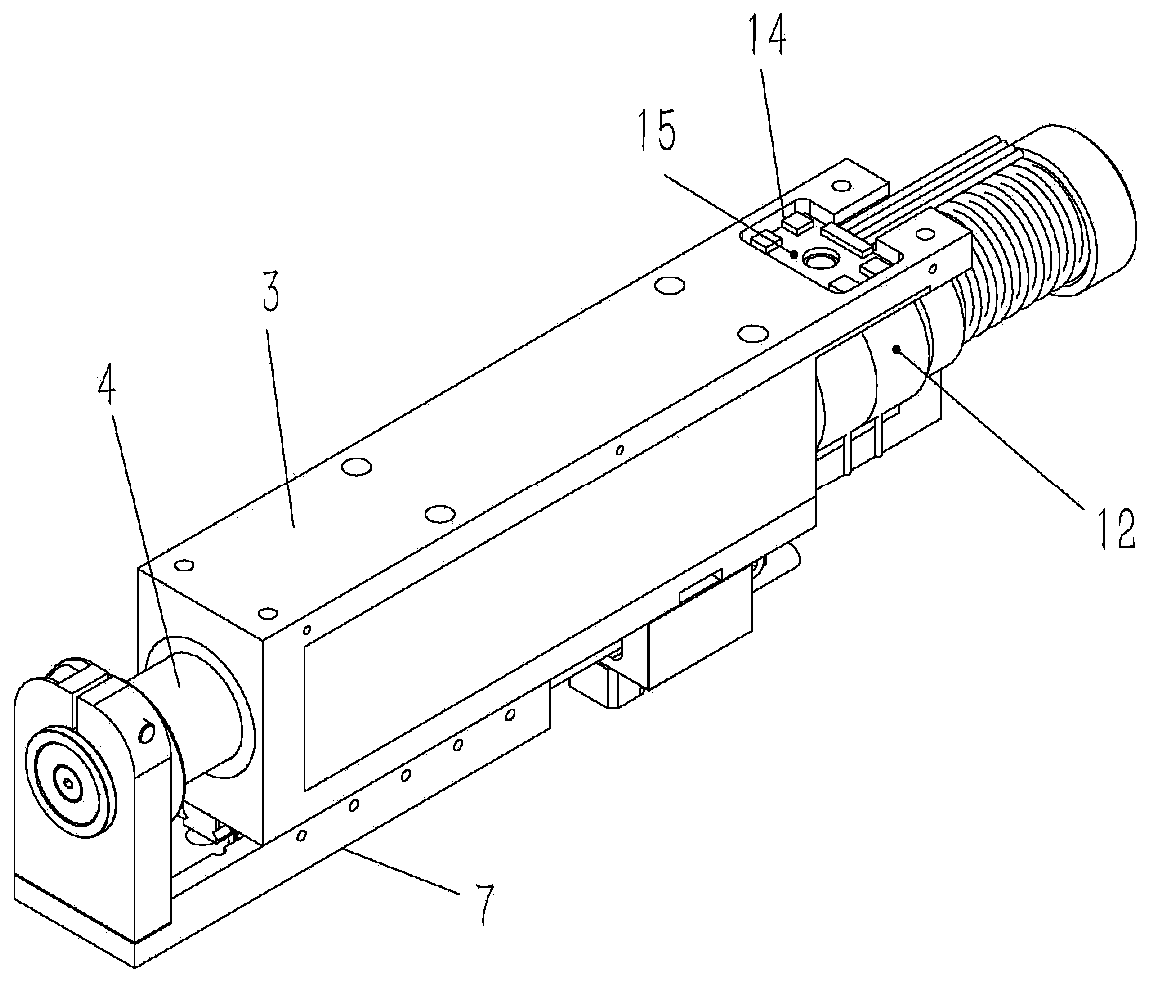

[0032] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

[0033] like Figure 1 to Figure 10 As shown, a linear motor module with a lateral opening structure includes a linear motor 1. The linear motor 1 includes a fixed base 3 and a mover 4 pierced in the fixed base 3. Both sides of the fixed base 3 are respectively provided with The open opening 5 that can reduce the width of the fixed base 3 is filled with sealant 6 at the open opening 5 on both sides, and the upper end of the fixed base 3 is provided with a sliding seat 7 connected with one end of the mover 4 .

[0034] Preferably, the top of the fixed base 3 is also provided with a grating reading head fixing seat 31, the bottom of the grating reading head fixing seat 31 is hidden with a limit sensor 32, and the upper end of the grating reading head fixing seat 31 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com