Planar serpentine coil radiating exchange water heater compact component and manufacturing method thereof

A technology of serpentine coils and water heaters, which is applied in the directions of heat exchanger shells, tubular elements, heat exchange equipment, etc., can solve the problems of unsightly space occupation, low production efficiency, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

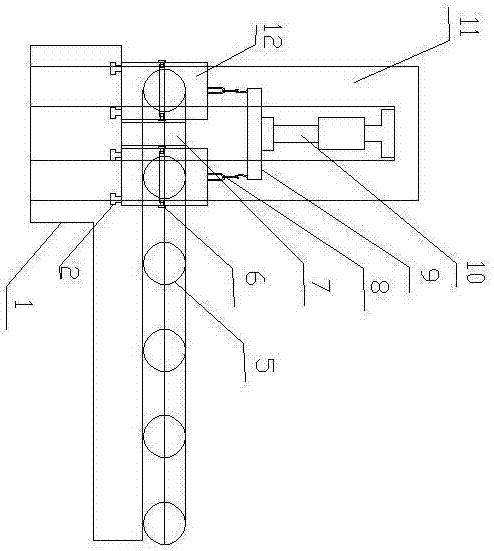

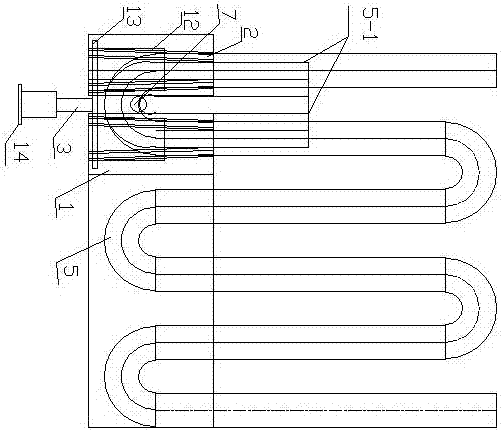

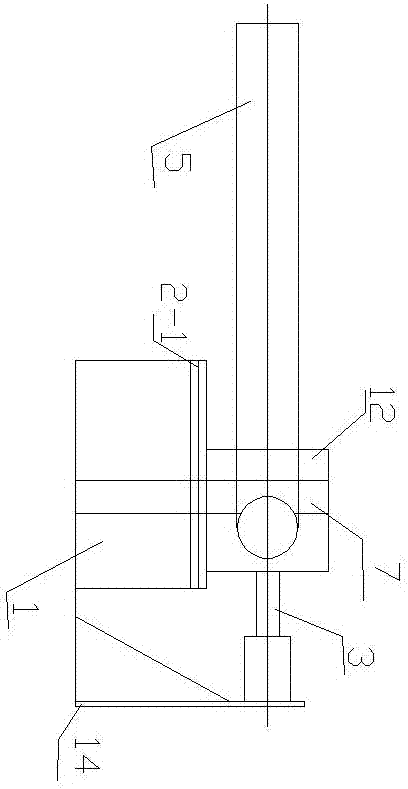

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 Shown:

[0027]A compact component of a planar serpentine coil heat exchange water heater and its manufacturing method, including an outer tube 5 constituting a water channel, an outer tube 5-1 of a water channel with a reduced distance, and an inner tube 15 of the water channel, and the outer tube 5 of the water channel is arranged There is a wire head seat 16 welded with inner flanging and a joint seat 17 welded with the inner pipe ring of the water channel, and also includes an annular coupling plate 18, a support 19, and the outer pipe of the water channel 5 is a straight pipe parallel to the same plane. And connect the planar serpentine coil that is formed by bending, the initial section and the end section of the water chann...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap