Double-station vulcanization chamber for plate vulcanization machine

The technology of a flat vulcanizing machine and a vulcanizing chamber, which is applied in the field of flat vulcanizing machine structure, can solve the problem of poor vulcanization preparation effect of the flat vulcanizing machine, and achieve the effect of simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

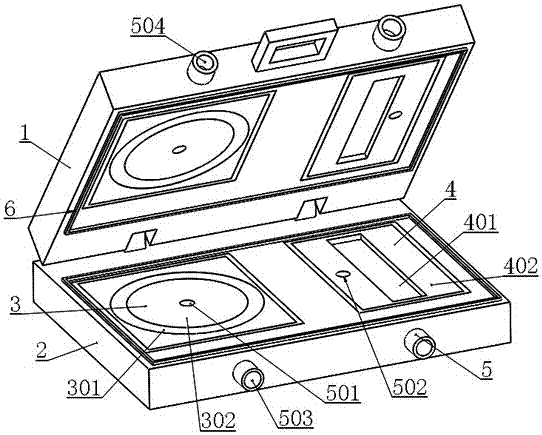

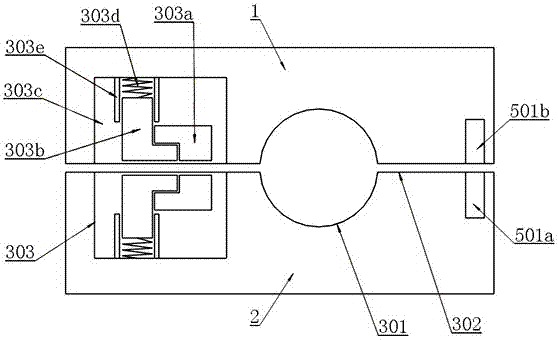

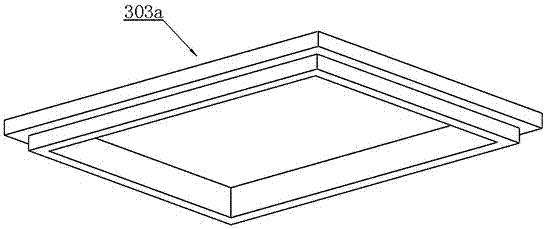

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a double-station vulcanization chamber for a flat vulcanizing machine includes an upper plate 1 and a lower plate 2 for vulcanizing the plate, and also includes an upper plate 1 and a lower plate 2 arranged between the upper plate 1 and the lower plate 2 and used for The first vulcanization chamber 3 for preparing O-rings by vulcanization, the second vulcanization chamber 4 for preparing rubber strips by vulcanization, and the upper plate 1 and the lower plate 2 are used for steaming A steam pipe 5 for heating and pressurizing the first vulcanizing chamber 3 and the second vulcanizing chamber 4.

[0024] In this embodiment, the dual-station vulcanization chamber refers to the first vulcanization chamber 3 for vulcanizing and preparing O-rings and the second vulcanizing chamber 4 for vulcanizing and preparing rubber strips, which makes the duplex The vulcanization chamber has the advantage of one-tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com