Gap-covering spliced type wooden plastic plate

A spliced, wood-plastic board technology, used in covering/lining, construction, building structure, etc., can solve the problem of wood-plastic board not being beautiful enough, and achieve the effect of not easy to loosen and tightly combined

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

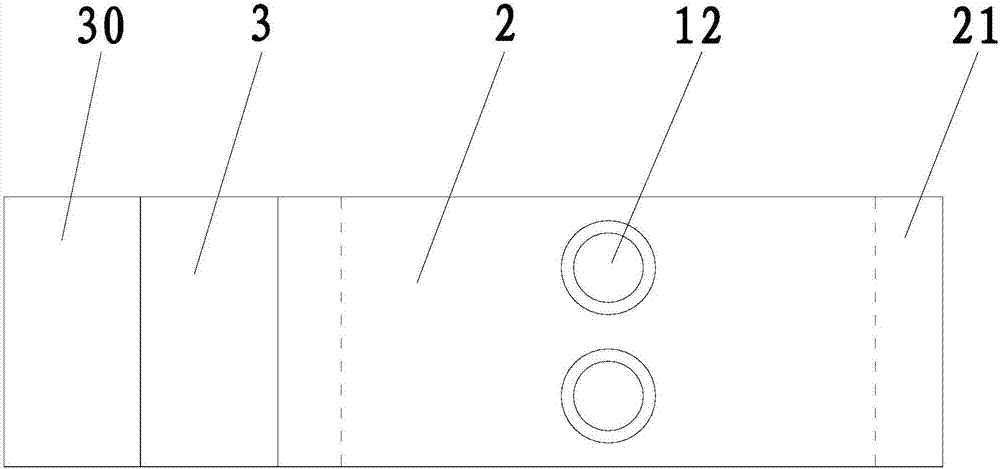

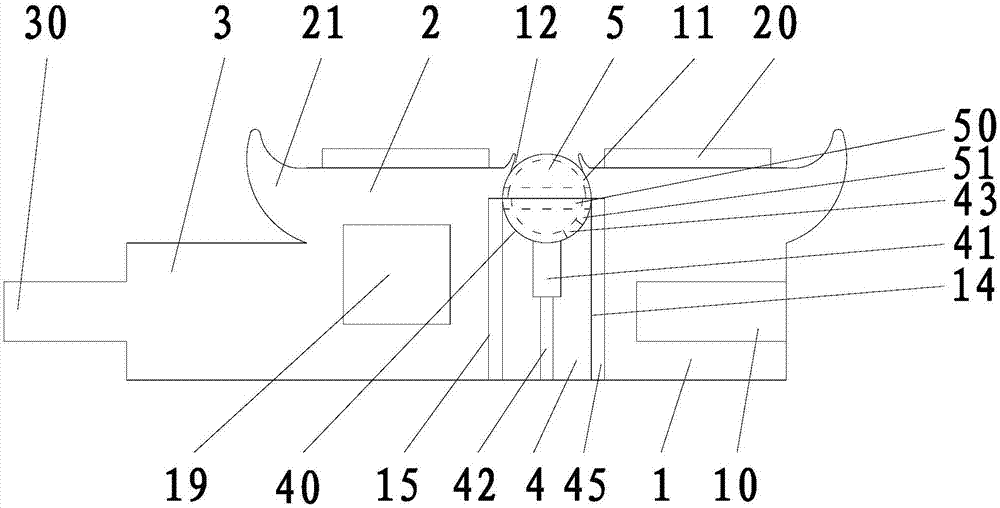

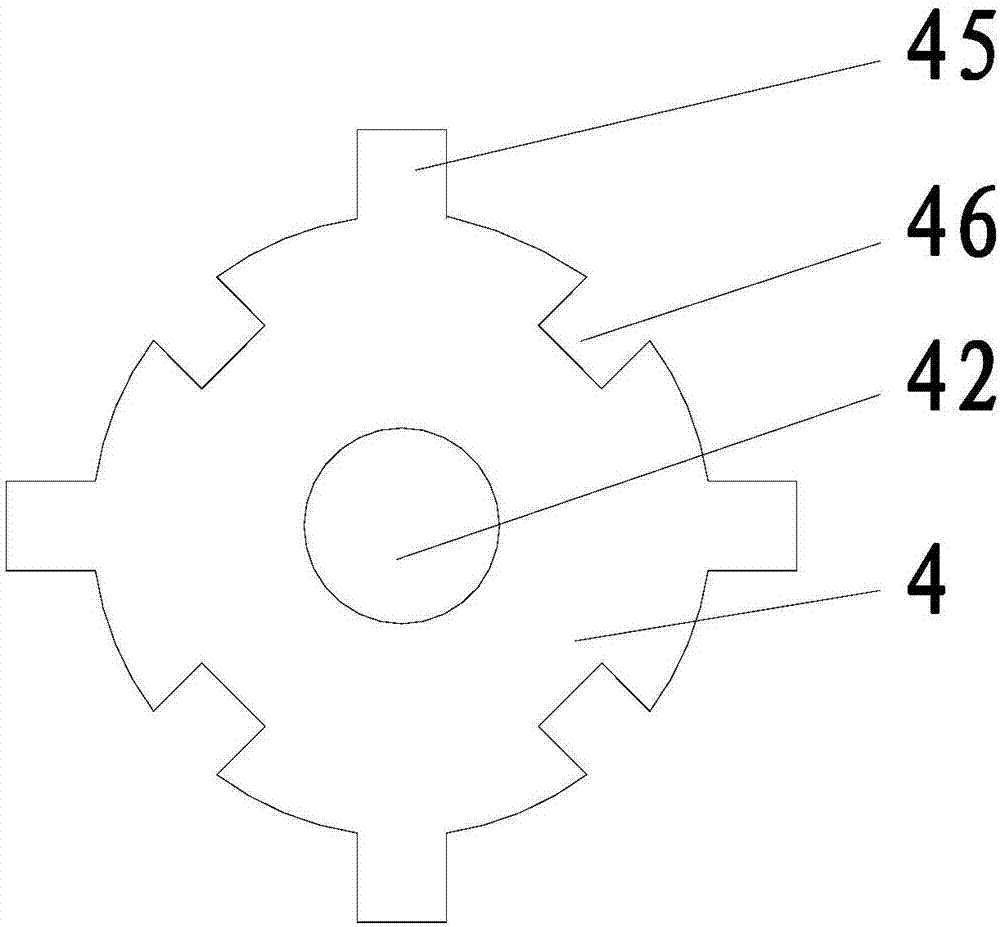

[0017] refer to figure 1 , figure 2 with image 3 , a seam-shielding spliced wood-plastic panel of the present invention, comprising a main body board, a fixing hole 14, a fixing plug 4, a shielding ball 5, and a special-shaped hole, the main body board is composed of a bottom board body 1 at the bottom and an outer layer at the top The board body 2 is composed of a connecting groove 10 on one side of the bottom board body 1, and a connecting plate 3 on the other side of the bottom board body 1, and a connecting convex strip matching the connecting groove 10 is fixed on the side of the connecting plate 3 30, the upper end of the bottom plate 1 is fixed with the outer plate 2, and the first decorative strip 21 is provided on both sides of the outer plate 2, and the lower end surface of the first decorative strip 21 is in the shape of an upwardly tilted arc, so A plurality of fixing holes 14 are arranged in the main body plate, and an opening end of the fixing holes 14 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com