Combined distribution cabinet

A combined power distribution cabinet and power distribution cabinet technology, which is applied in substation/power distribution device shell, substation/switchgear cooling/ventilation, fire rescue, etc., can solve the aging of internal electronic parts, affect the service life, and assemble efficiency Reduce problems such as increasing heat dissipation speed, avoiding rust, increasing installation efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

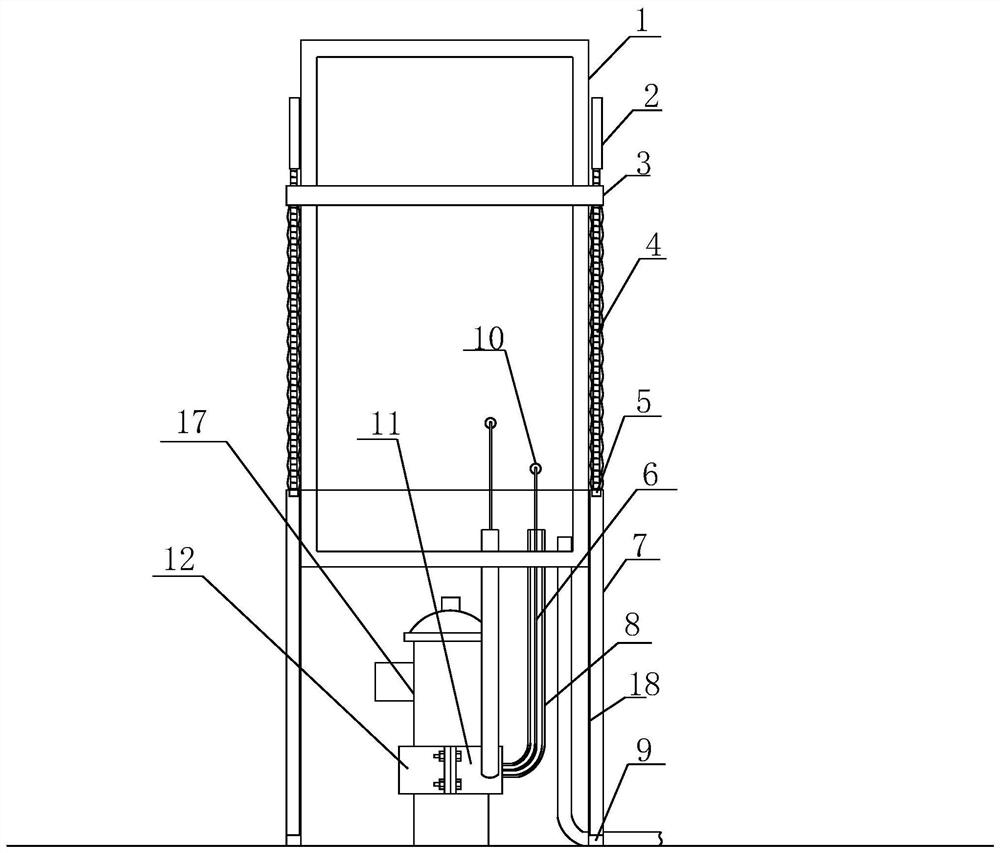

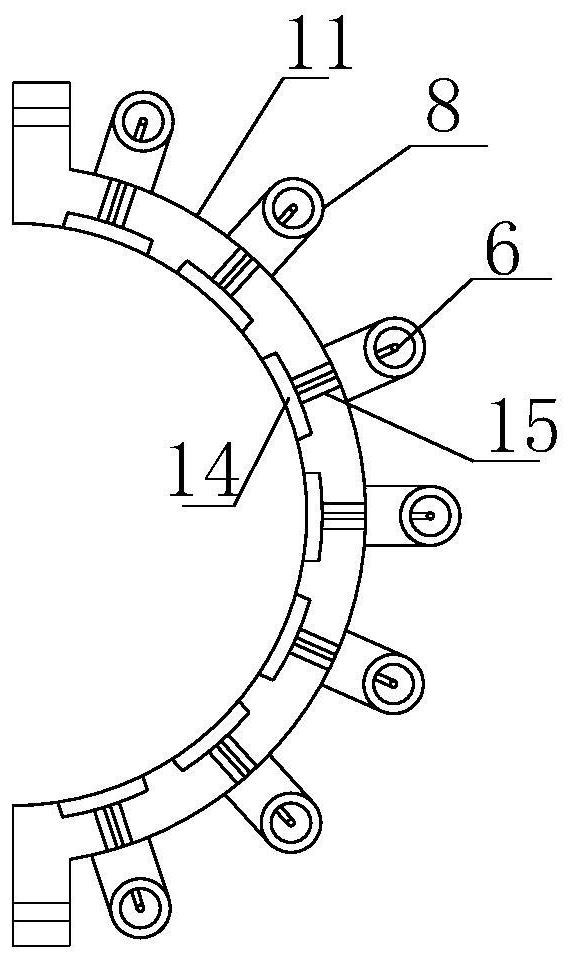

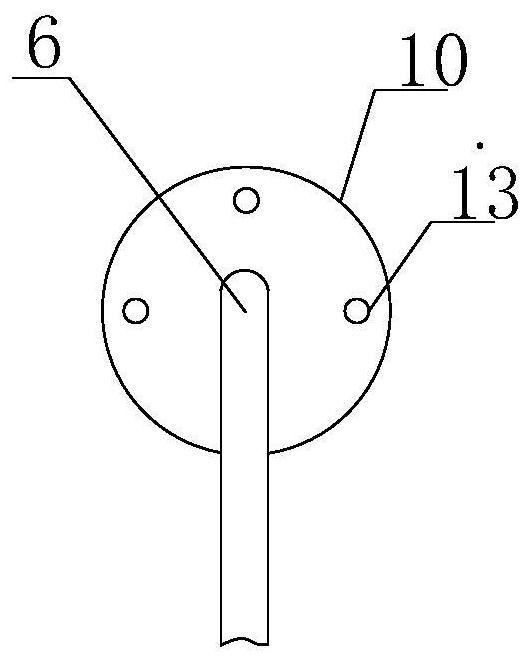

[0017] Such as figure 1 , figure 2 with image 3 As shown, the combined power distribution cabinet includes a fire hydrant 17 poured and fixed on the ground and a power distribution cabinet 1 arranged on the upper end of the fire hydrant 17. A fixture is provided on the fire hydrant 17, and the fixture includes a first arc-shaped plate 12 and the second arc-shaped plate 11, the inner wall surface of the second arc-shaped plate 11 is embedded with more than one first copper sheet 14, the inner wall surface of the first copper sheet 14 is offset against the outer wall surface of the fire hydrant 17, the second The outer wall of the two arc-shaped plates 11 is facing the first copper sheet 14 and is provided with a through hole 15. The outside of the through hole 15 is welded and fixed to install a metal pipe 8, and the upper end of the metal pipe 8 extends through the bottom surface of the power distribution cabinet 1. To the inside of the power distribution cabinet 1, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com