Adjustable flaw detection fixture for aero-engine parts

An aero-engine, adjustable technology, applied in workpiece clamping devices, manufacturing tools, material analysis using radiation, etc., can solve the problems of parts being difficult to clamp, unable to adjust the size or thickness, etc., to increase thickness and facilitate convenience Adjustment, beneficial to the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

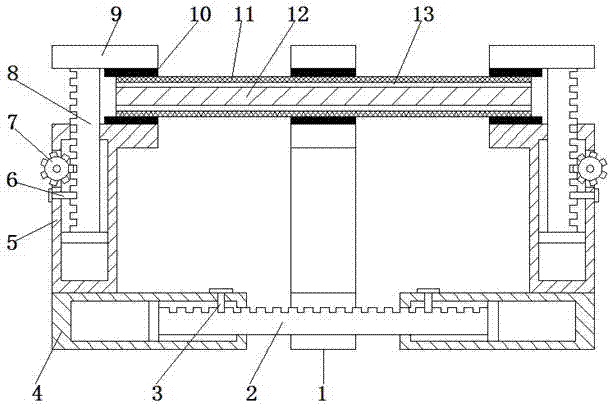

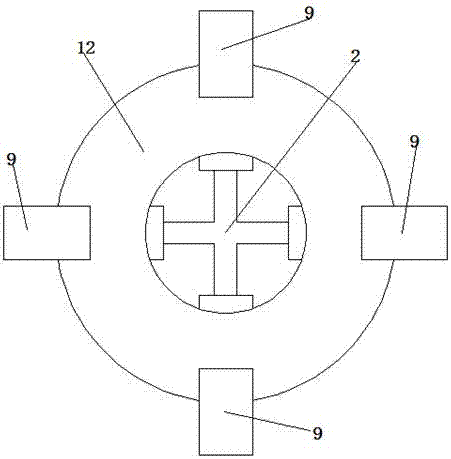

[0021] as attached figure 1 to attach figure 2 Shown:

[0022] The invention provides a technical solution: an adjustable flaw detection fixture for aero-engine parts, including a fixture body 1, a cross-shaped adjustment frame 2, an adjustment screw 3, a base sleeve 4, a clamping base 5, a fixing screw 6, and an adjustment wheel 7. Adjusting column 8, clamping block 9, rubber protective pad 10, lead plate 11, workpiece 12 and X-ray film 13, the bottom of the fixture body 1 is provided with a cross-shaped adjustment frame 2, and the four ends of the cross-shaped adjustment frame 2 The adjusting screws 3 are respectively installed inside the four base sleeves 4; the top of the tail of the base sleeve 4 is connected to the clamping base 5 by welding, and the clamping part on the top of the clamping base 5 is equipped with a rubber protective pad 10; The adjustment columns 8 are installed inside the clamping base 5 through the fixing screws 6, and the adjustment wheels 7 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com