Spark plug

A spark plug and center electrode technology, which is applied in the field of spark plugs, can solve the problems of increased consumption of ground electrode base material, ground electrode breakage, and inability to perform spark plug performance, etc., to achieve the effect of suppressing abnormal combustion and suppressing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

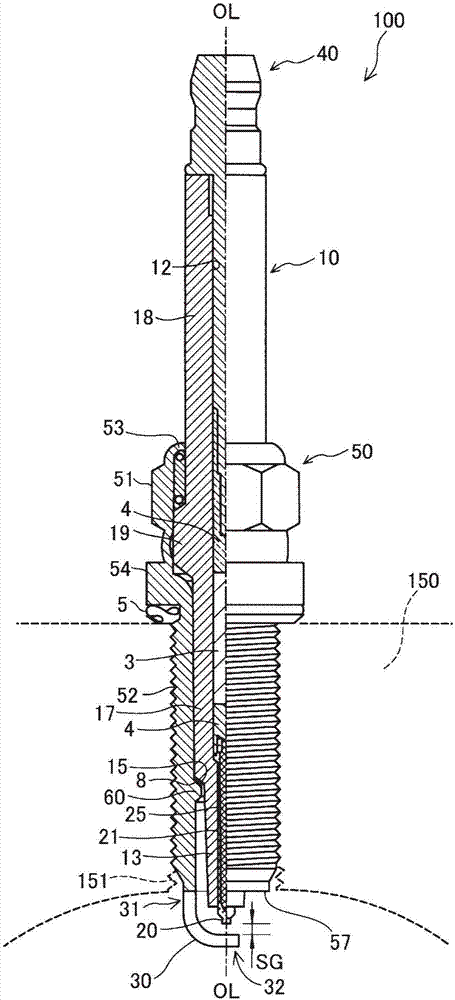

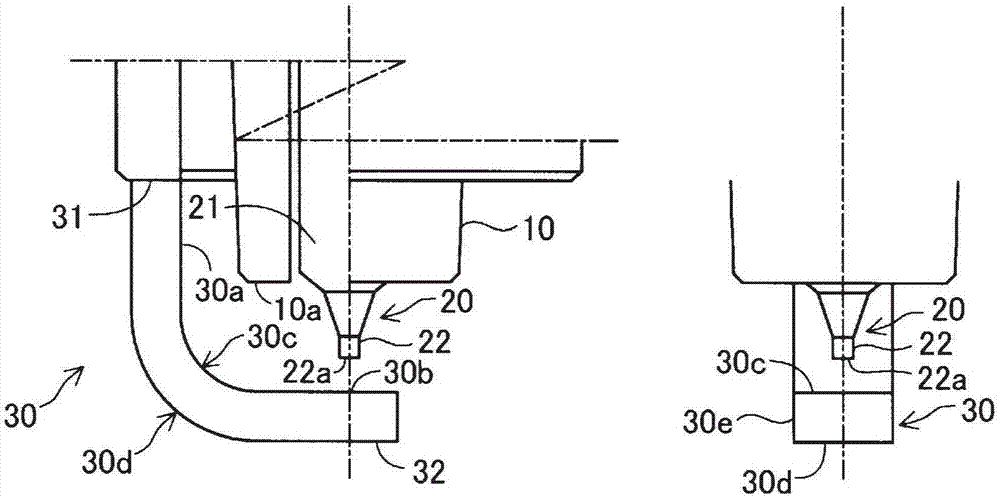

[0075] Hereinafter, a spark plug 100 as a spark plug of the present invention will be described with reference to the drawings. figure 1 It is a partial sectional view of the spark plug of this embodiment. exist figure 1 In , the central axis in the longitudinal direction of the spark plug 100 is indicated by an axis OL of a one-dot chain line. The right side of the axis OL shows an external front view, and the left side of the axis OL shows a cross-sectional view of the spark plug 100 cut by a section passing through the central axis of the spark plug 100 . Below, with figure 1 The lower side of the spark plug 100 in the axis OL direction, that is, the side exposed to the interior of the combustion chamber is the front end side of the spark plug 100, and the upper side, that is, the side where the spark plug cord is installed is the rear end side. The spark plug 100 includes an insulator 10 , a center electrode 20 , a ground electrode 30 , a terminal electrode 40 , and a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com