Method for fixing measured object from bottom surface

An object and bottom surface technology, applied in the field of three-dimensional measurement, can solve the problem of occupying the surface area of the object, and achieve the effect of improving work efficiency and facilitating three-dimensional measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

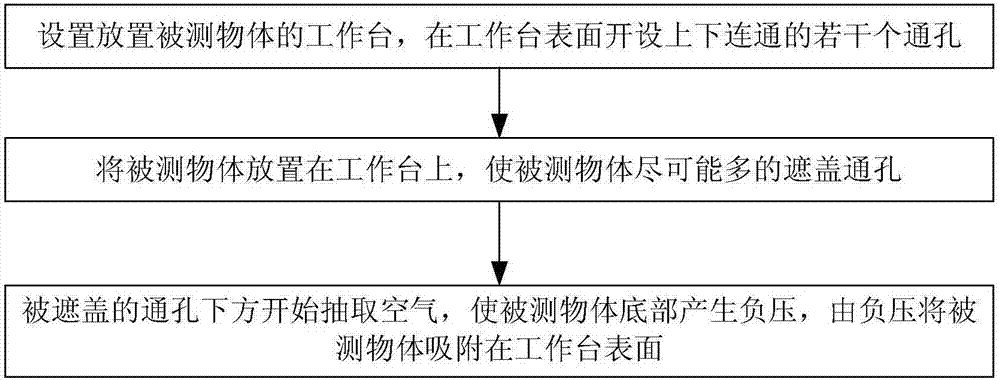

[0019] Such as figure 1 The shown method for fixing the measured object from the bottom surface includes the following steps: (a) setting a workbench for placing the measured object, and opening several through holes connected up and down on the surface of the workbench; (b) placing the measured object on the On the working table, make the measured object cover the through hole as much as possible; (c) start to draw air from the bottom of the covered through hole, so that the bottom of the measured object will generate negative pressure, and the negative pressure will absorb the measured object on the working table surface. The extraction of air in step (c) is carried out by a vacuum pump. A filter screen is arranged in the through hole. The diameter of the through hole is 2-5mm. In the present invention, a number of through holes connected up and down are provided on the surface of the workbench, and the measured object is placed on the workbench, so that the measured obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com