Wire harness storage and lifting device

A lifting device and wire harness technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as easy entanglement of wire harnesses, increased labor time, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention will be further described.

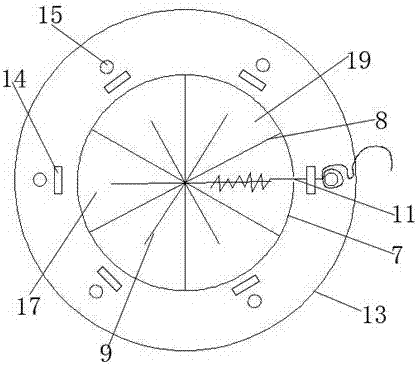

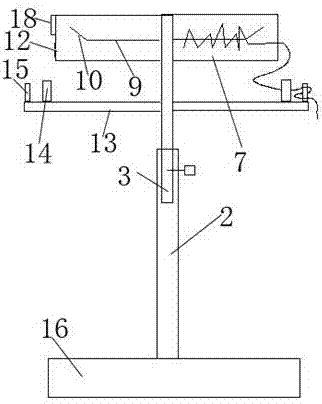

[0023] like Figure 1-3 As shown, a wire harness storage and lifting device includes a storage tray 7, a distribution tray 13 and a base 16 connected sequentially through the lifting rod 1 from top to bottom, the storage tray 7 is located on the top of the lifting rod 1, and the base 16 Located at the bottom of the lifting rod 1; the storage tray 7 is a cylindrical accommodation compartment with an open upper end, and the storage tray 7 divides the accommodation compartment into 6 partitions 17 through 3 partitions 8 passing through the center of the circle. The dividing plate 8 can make the wire bundles in the adjacent grid block 17 relatively independent, and there will be no winding problem of different wire harnesses. Each grid block 17 is provided with a winding rod 9 that radiates from its center to the circumference. Threading holes 11 are provided on the circumferential wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com