In-situ additive manufacturing equipment for continuous fiber reinforced high performance resin composites

A resin composite material, additive manufacturing technology, applied in the direction of additive processing of solid materials and liquid materials, processing and manufacturing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

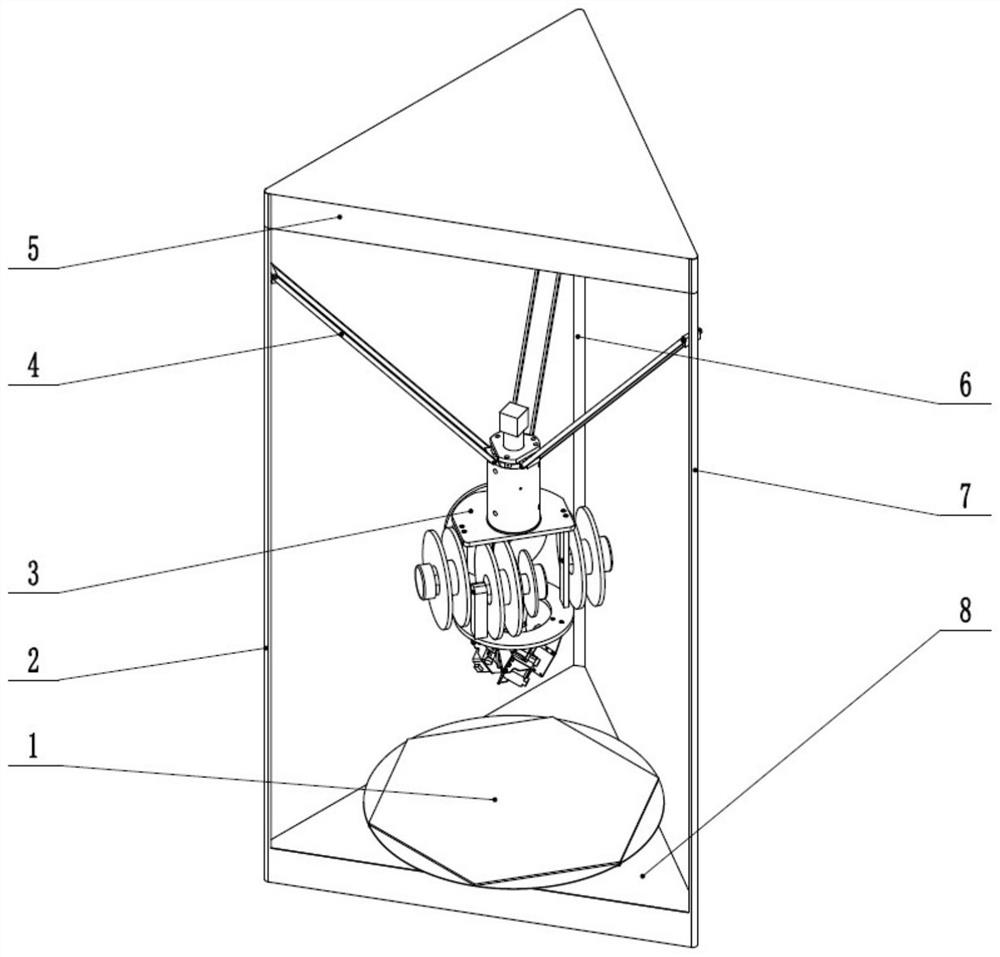

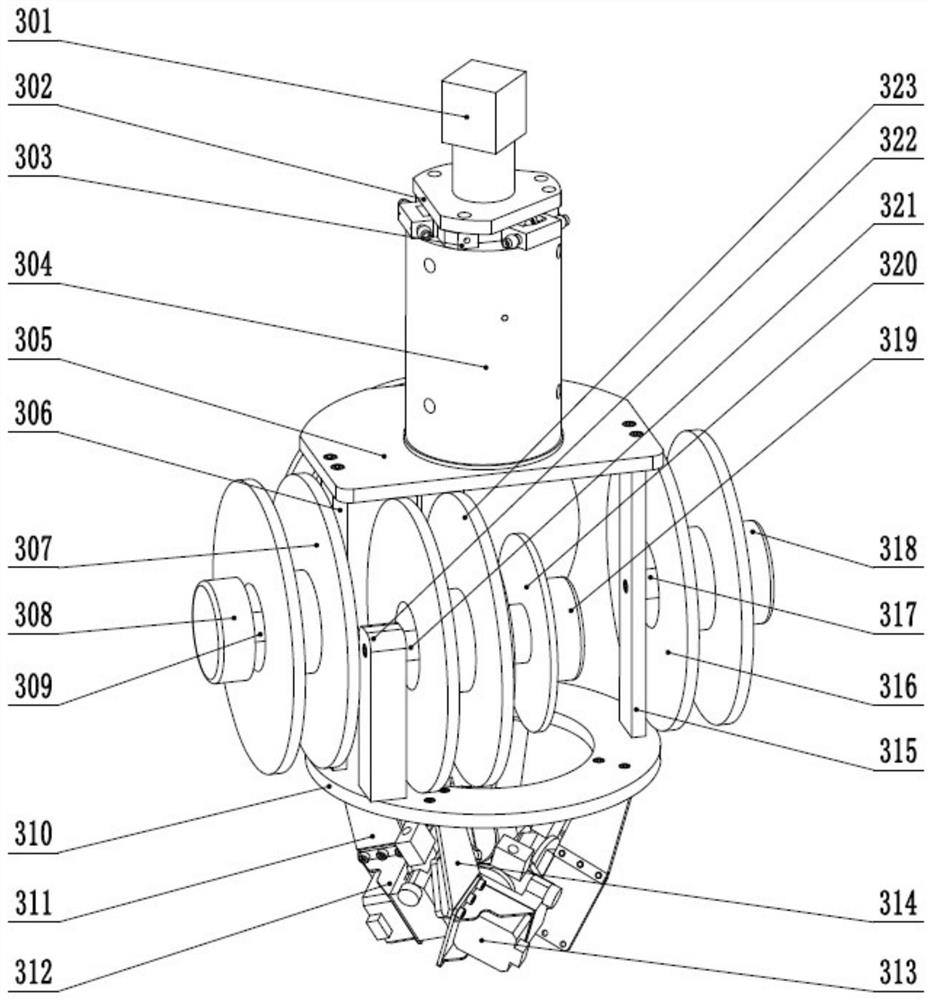

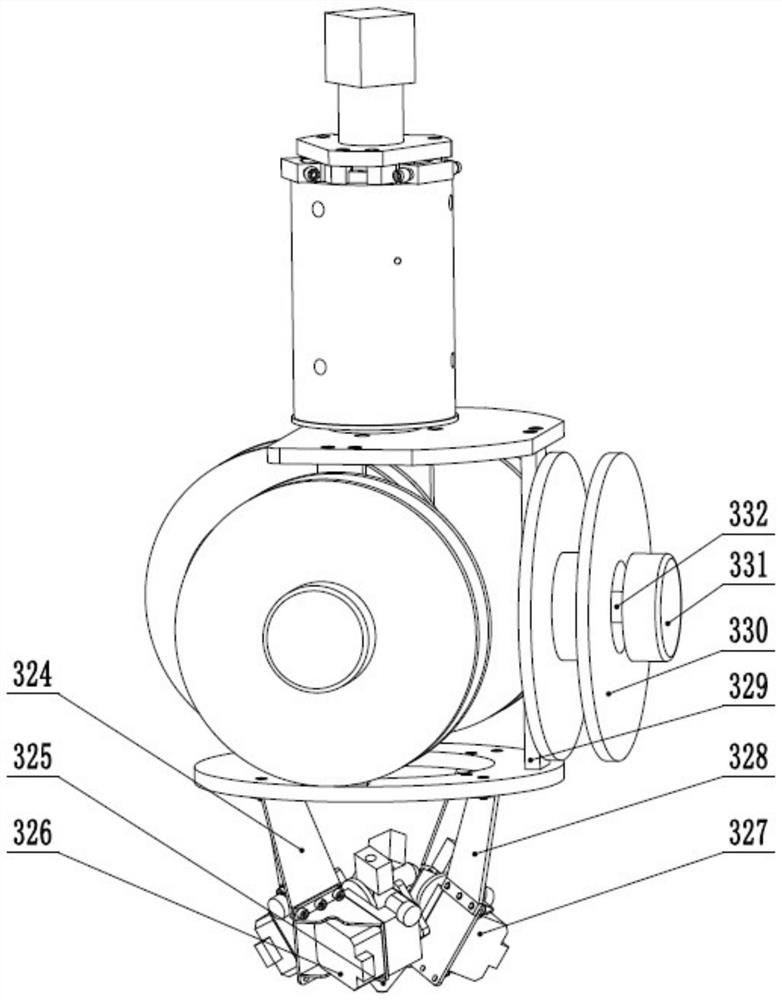

[0036] Such as figure 1 As shown, an in-situ additive manufacturing equipment for continuous fiber-reinforced high-performance resin composite materials consists of a printing heat bed 1, a first support column 2, a print head 3, a support rod 4, an upper support plate 5, and a second support column 6 , the third support column 7, the lower support plate 8 and other components.

[0037] The printing hot bed 1 is fixedly connected to the lower support plate 8 , and the upper support plate 5 and the lower support plate 8 are fixedly connected through the first support column 2 , the second support column 6 and the third support column 7 . Each support column is provided with a slider that can sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com