A drag type vibration suppressor

A compactor and pressure adjustment technology, which is applied in compactors, agriculture, applications, etc., can solve the problems of uneven pressure, insufficient compaction pressure, winding and other problems, and achieve the effect of improving the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

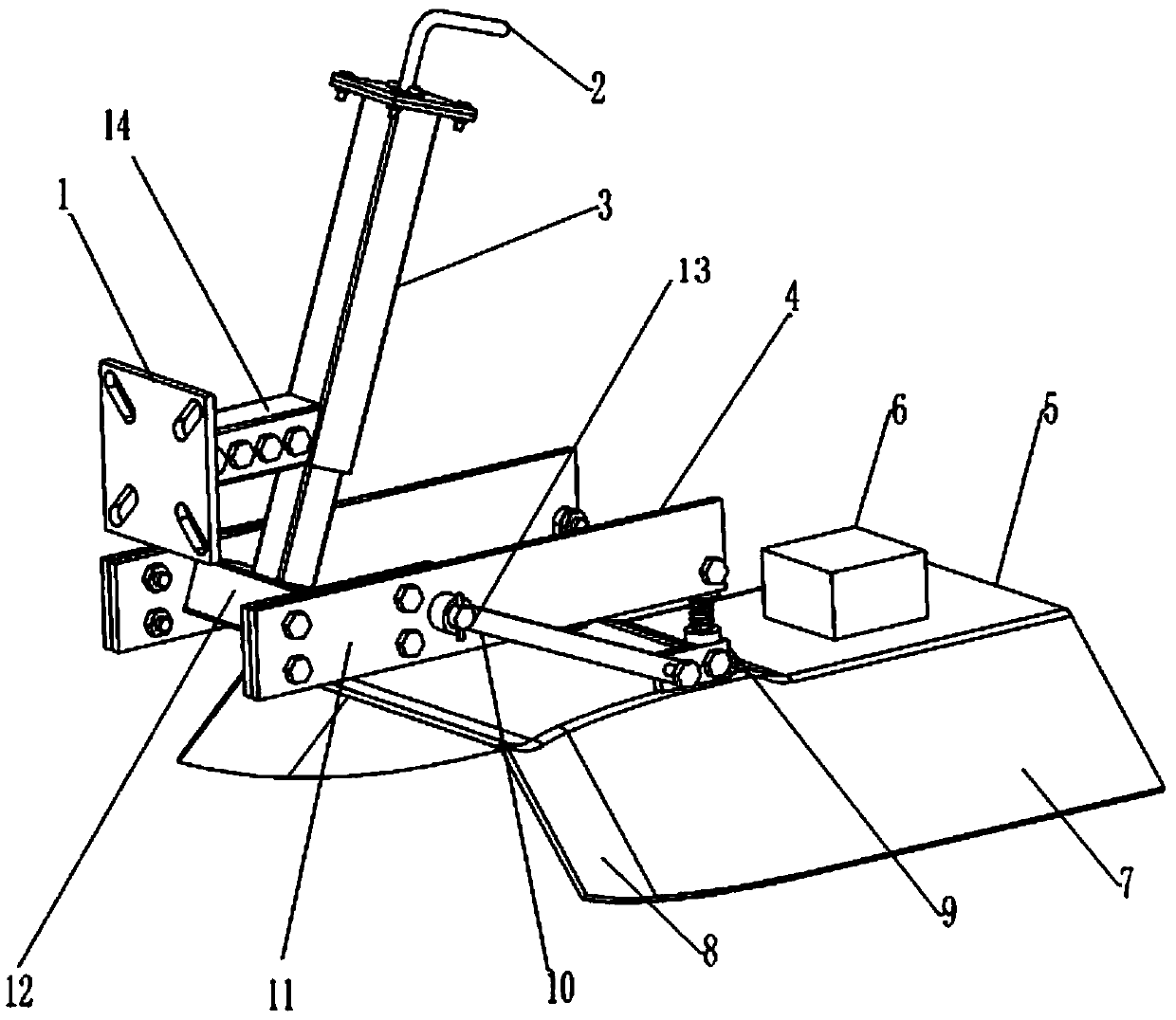

[0016] Such as figure 1 with figure 2 As shown, the front end of the side pressing plate 7 of the present invention has a side soil collecting plate 8, and the soil collecting plate 8 is in the shape of an outward arc, and its outline shape is a star-shaped line equation x is the bending length of the front part of the side soil collecting plate 8, y is the bending width of the front part of the side soil collecting plate 8, the value range of b is: 15≤b≤20, The value range of is: During the advancing process of the dragging suppression device, the side soil collecting plates 8 can gather the soil on both sides toward the middle, which is beneficial to the formation of ridges.

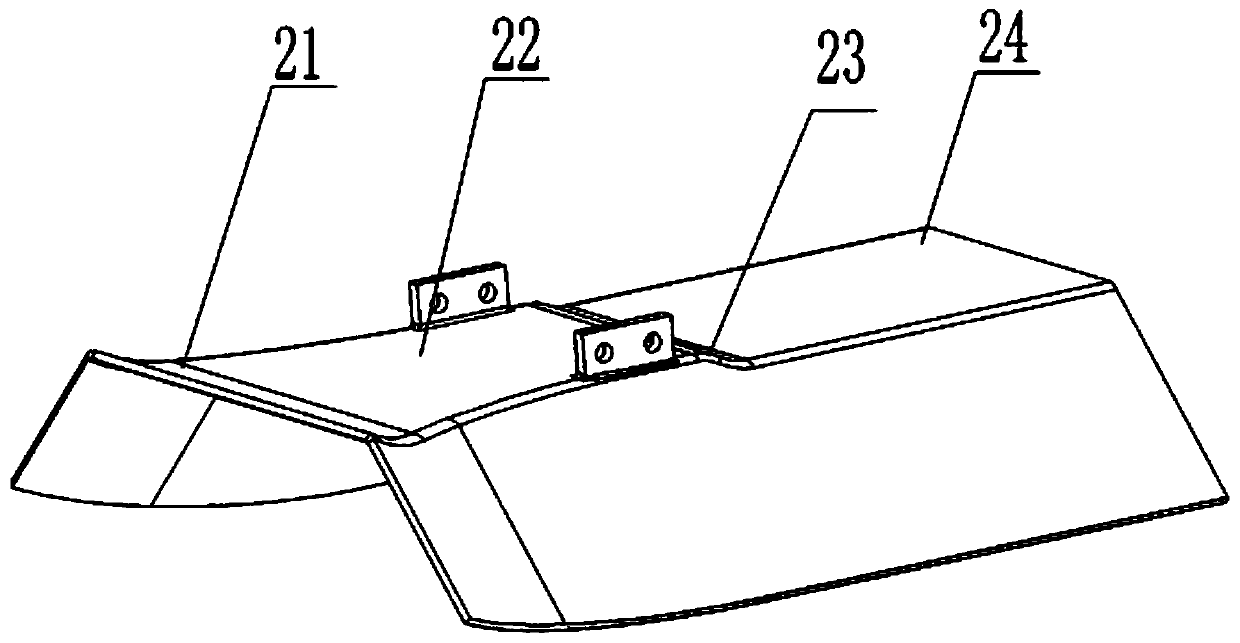

[0017] The earth retaining plate 21 at the front end of the top pressing plate front plate 22 of the present invention is upwardly tilted, and the contour shape of the earth retaining plate 21 is an involute curve Among them: x is the horizontal length of the soil retaining plate 21, y is the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com