Ball screw

A technology of ball screw and ball, applied in bearings, linear motion bearings, bearing components, etc., can solve problems such as labor-intensive, poor lubricity, and inability to supply lubricating oil, and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The ball screw of the present invention is preferably applied to various equipment such as mechatronic products such as precision positioning tables and detection devices.

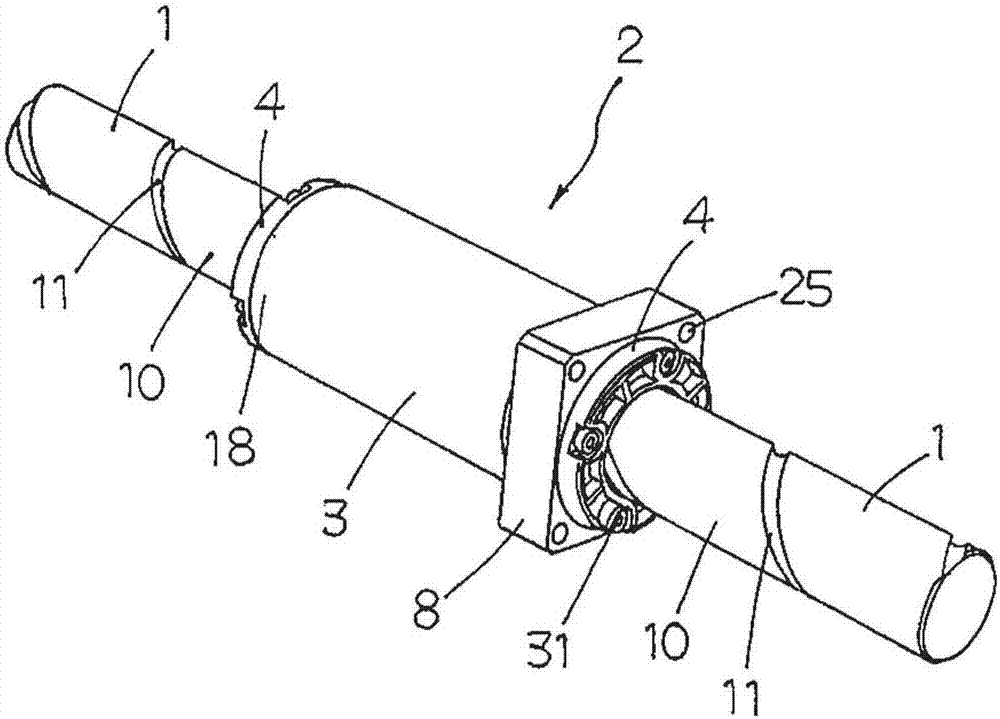

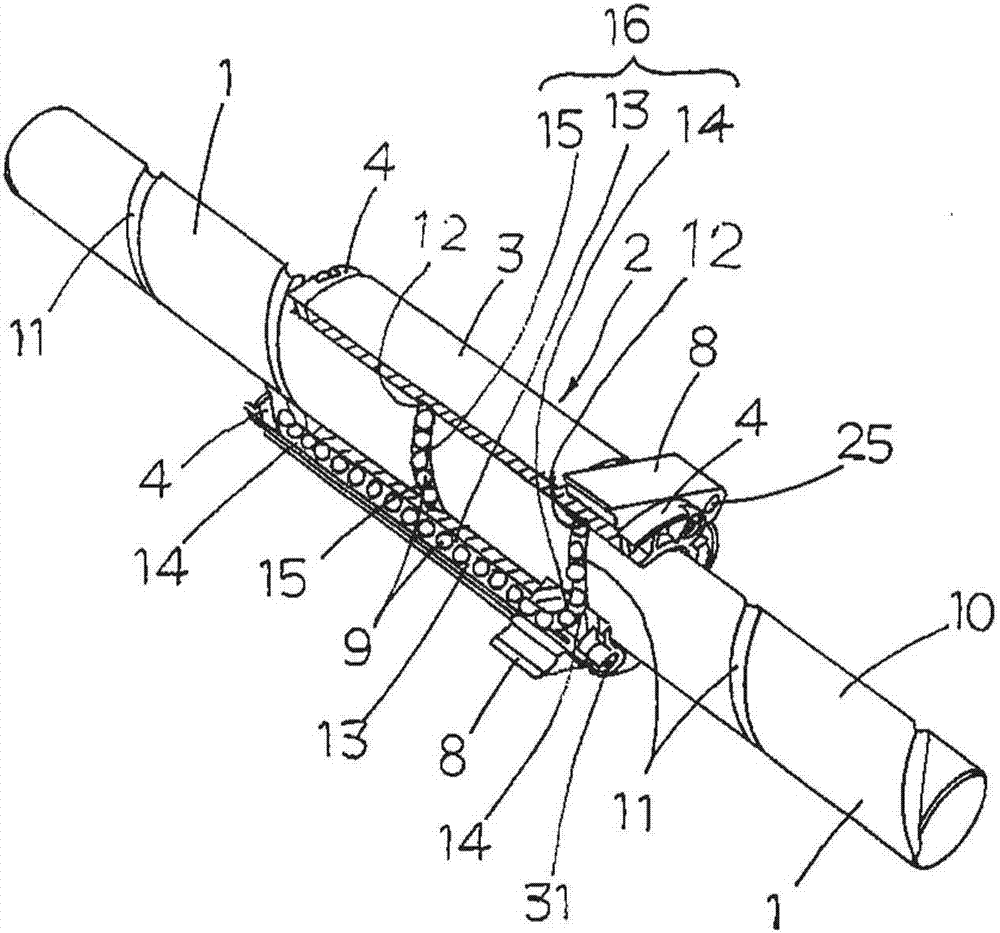

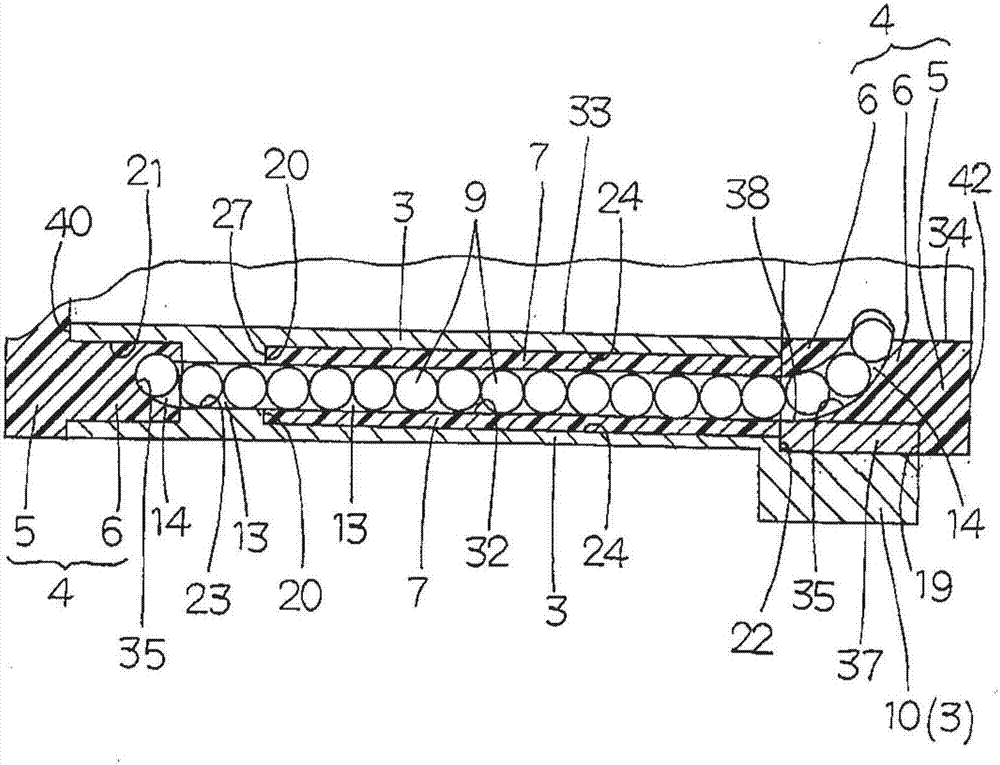

[0070] Hereinafter, an embodiment of the ball screw according to the present invention will be described with reference to the drawings. The ball screw of the present invention generally has: a rotatable screw shaft 1 on which a helical groove 11 (first helical groove) is formed in the axial direction on its outer peripheral surface 10; and a cylindrical nut 2 formed with an insertion The screw shaft 1 has an insertion hole 33 (first insertion hole), and a helical groove 12 (second helical groove) opposite to the helical groove 11 is formed in the axial direction on the inner peripheral surface 17 thereof. This ball screw is configured such that a plurality of balls 9 as rolling elements roll in a helical track path 15 formed by a helical groove 11 and a helical groove 12 as the screw shaft 1 rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com