Device and method for hoisting container on railway flatcar with F-TR locks

A container and F-TR technology, which is applied in the direction of program control, instrument, control/regulation system in the sequence/logic controller, can solve the problems of economic loss, fast container lifting speed, vehicle derailment, etc., and achieve convenient operation, The effect of avoiding vehicle derailment safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

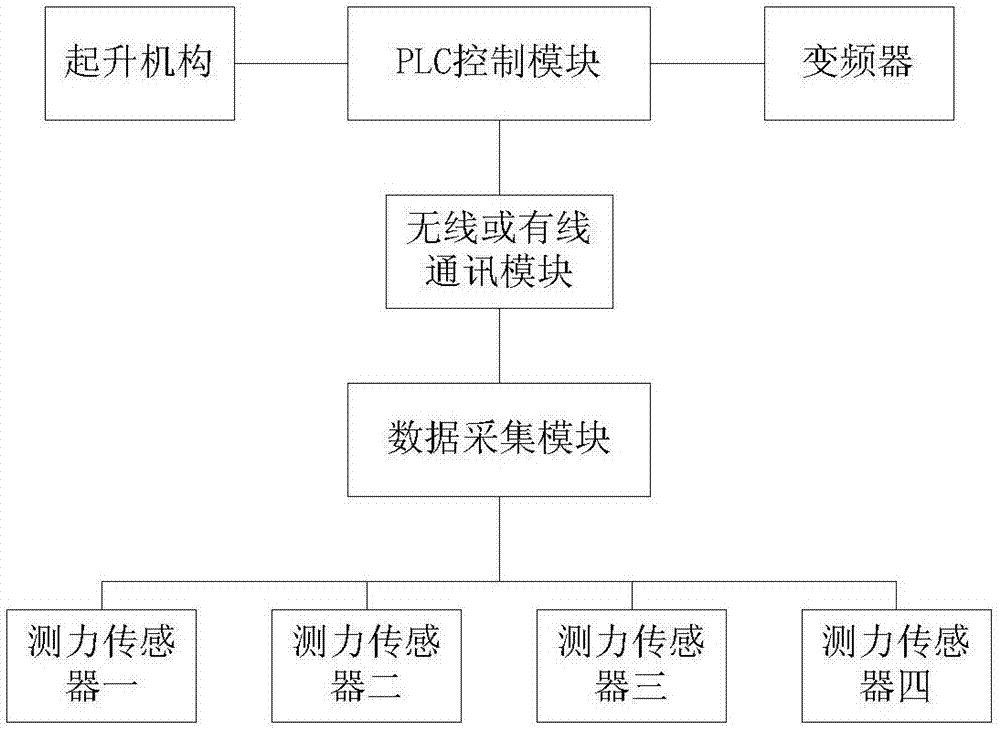

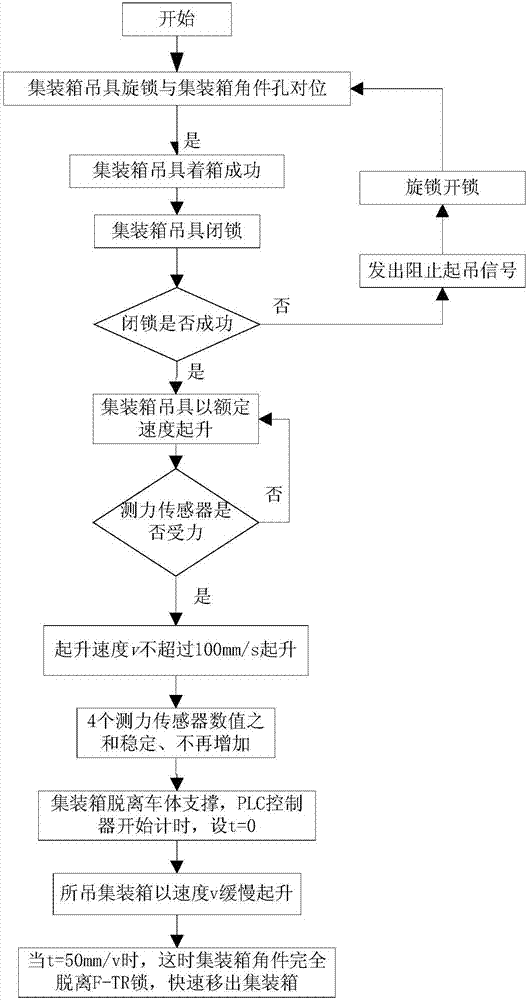

[0021] like figure 1 As shown, the device for lifting the container on the railway flat car with the F-TR lock, including the twist lock force measuring module of the container spreader, the data acquisition module, the wireless or wired communication module, the PLC control module, the frequency converter, the lifting motor, lifting mechanism;

[0022] The twistlock force measuring module includes force sensor one, force sensor two, force sensor three and force sensor four installed on the four twist locks of the container spreader. The data acquisition module is respectively connected with each force sensor of the force measurement module, and reads the force value of each twistlock during the container lifting process;

[0023] The PLC control module receives the force value of each twistlock collected by the data acquisition module through the wireless or wired communication module, and processes the detection data;

[0024] The frequency converter receives the control c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com